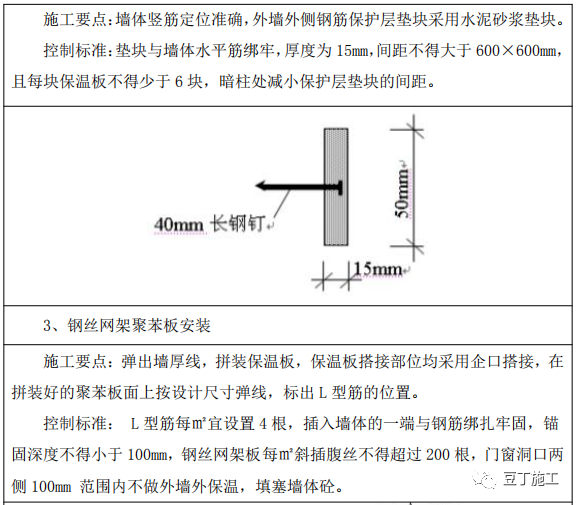

The installed anchor shall be level with the thermal insulation layer.

(3) The number of anchors shall not be less than 5 per square meter, the distance between the installation hole and the outer edge of the insulation board shall not be less than 50mm, and anchors can be added at the door and window openings.

preparation description this part is applicable to the construction of polystyrene board insulation and rock wool board insulation, and the specifications are as follows: jgj144-2008 technical specification for exterior wall external insulation engineering gb/t23483-2009 test method for heat transfer coefficient and heating capacity of building envelope jgj/t132-2009 test standard for energy efficiency of residential buildings jc/t841-2007 alkali resistant glass fiber mesh cloth II Construction preparation (I) technical preparation 1.

Wall conditions (1) the wall is clean and free of pollution.

Prepare special construction scheme and make disclosure.

Construction preparation (I) technical preparation 1.

5.

preparation instructions gb50204-2015 code for acceptance of construction quality of concrete structures GB / t23483-2009 test method for heat transfer coefficient and heating capacity of building envelope JGJ / t132-2009 test standard for energy conservation of residential buildings II.

quality control standards and inspection standards 1.

III.

(3) Preparation of operation conditions 1.

(2) Machine and tool preparation 1.

The horizontal and vertical spacing shall not be more than 500 mm, and the distance from the edge of the base course shall not be less than 60 mm.

This process manual is the construction process of external wall insulation works.

2.

3.

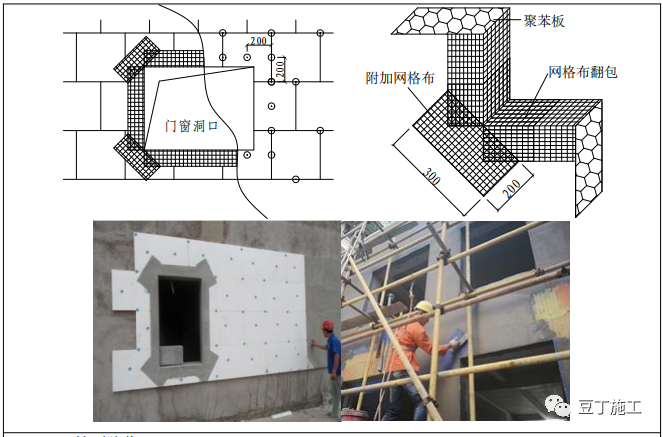

The door and window openings and external corner edges shall be reinforced.

The standard plate size is 2.4 × 0.6m。 III.

Main tools: line support plate, guiding rule, tape measure, internal and external angle trowel, etc.

(5) after the inner formwork is removed, the bolt holes shall be tightly blocked.

The specific installation quantity of the anchor shall be determined according to the drawing.

Prepare special construction scheme and conduct disclosure.

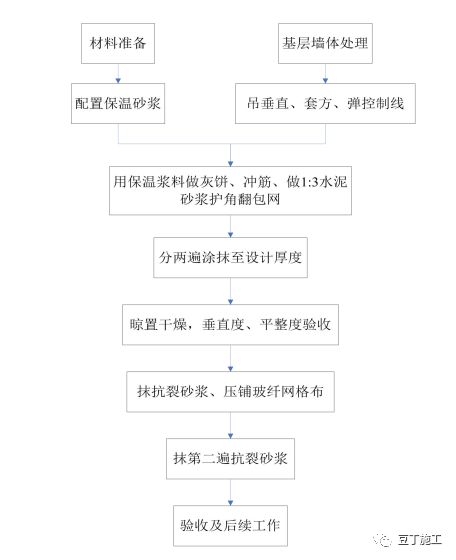

construction process (I) process flow (II) key points of construction IV.

The anchoring depth shall be 50 mm.

The materials are qualified in the mobilization retest, such as the thermal conductivity, density, compressive strength or compressive strength of the insulation board, the bonding strength of the mortar, the mechanical properties and corrosion resistance of the alkali resistant mesh cloth, etc.

Anchor bolt pull-out test: under standard experimental conditions, the pull-out strength of anchor bolt of concrete wall shall not be less than 0.6MPa, and that of autoclaved aerated block wall shall not be less than 0.3MPa.

The overlapping width of mesh cloth pressing in cloth and cloth is 100mm, the overlapping length of upper and lower cloth is 80mm, and a layer of 300mm is added to the external corner of window opening × 200mm mesh cloth for reinforcement.

Construction preparation (I) technical preparation 1.

(2) The wall surface shall be flat and less than 4mm / 2m.

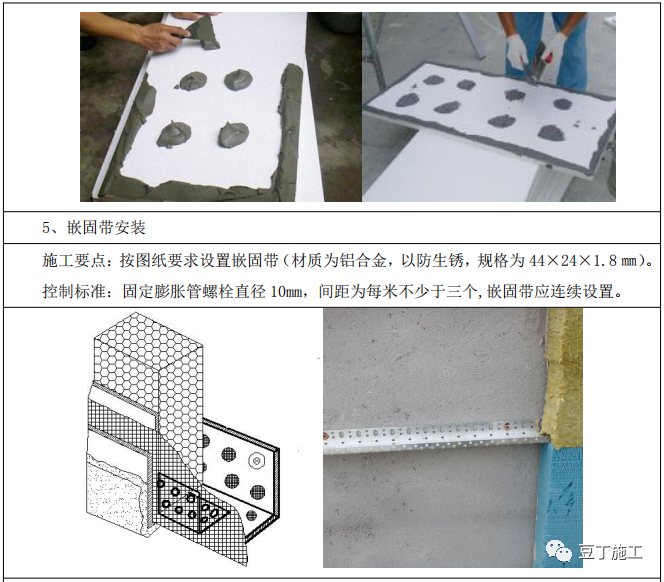

The effective bonding area ratio between the insulation board and the base course shall not be less than 70%.

According to the insulation materials and construction methods, the external wall insulation can be divided into five parts.

Installation of external scaffold or hanging basket is completed.

2.

Part I construction process of post bonded insulation board I.

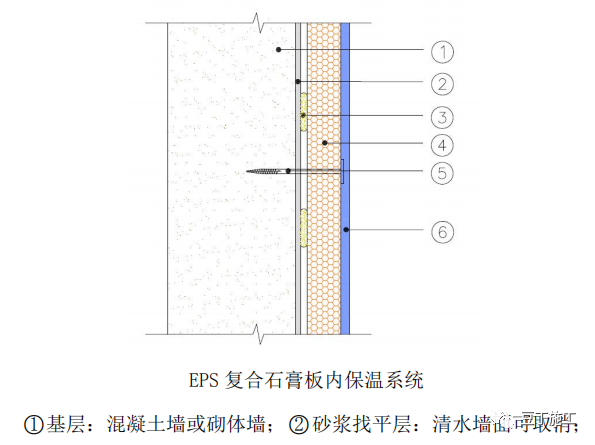

It mainly includes: Post bonded insulation board, cast-in-situ composite insulation external formwork, insulation mortar plastering, built-in insulation system of large formwork, and internal insulation system of composite insulation board.

2.

The anchor can be installed more than 24 hours after the thermal insulation board is pasted.

(3) The wall surface is basically dry.

construction process (I) process flow (II) key points of construction (IV) quality control standards and inspection standards (1) wood shall be placed at the bottom of the thermal insulation board when stacking; Stack by category and hang signboards.

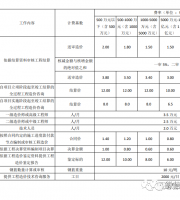

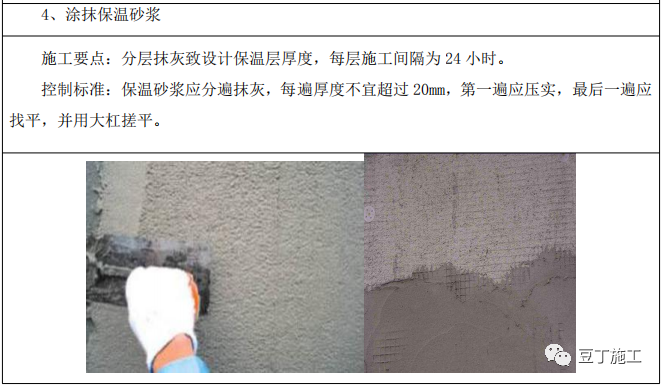

(7) The allowable size deviation and performance requirements of composite insulation external formwork are as follows: Part III construction process of insulation slurry plastering I.

preparation instructions this part is applicable to the construction of EPS insulation mortar and vitrified micro bead insulation mortar, The specifications are as follows: jgj144-2008 technical specification for exterior wall external insulation engineering jg158-2004 rubber powder polystyrene particle exterior wall external insulation system GB / t23483-2009 test method for heat transfer coefficient and heating capacity of building envelope JGJ / t132-2009 test standard for energy efficiency of residential buildings JC / t841-2007 alkali resistant glass fiber mesh cloth II.

(2) Machines and tools preparation 1.

There shall be no less than 5 anchors per square meter and the spacing shall not be greater than 500mm on any non main specification board.

Main tools: thread support plate, guiding rule, tape measure, internal and external angle trowel, etc.

(2) The composite insulation external formwork shall be pre assembled on site before installation, and the size shall be checked.

Drawing test of insulation board: under standard test conditions, the drawing strength of insulation board shall not be less than 0.1MPa.

2.

Mechanical equipment: electric cutting machine, impact drill, grinder, mixer, etc.

Inspection standard part II construction technology of cast-in-situ composite insulation external formwork I.

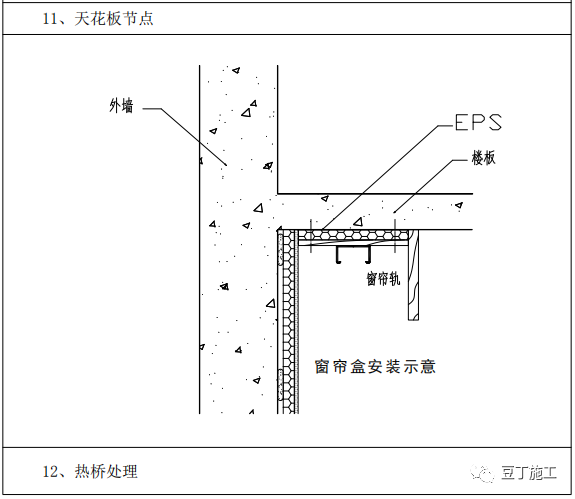

The door and window frames or auxiliary frames are installed, the screw holes of the external wall are sealed tightly, and the embedded parts and connectors of various household pipelines and air conditioners are installed.

2.

(4) The horizontal joint of the splicing joint of the composite insulation external formwork shall be filled with sponge strip or pasted with sealing tape during splicing.

2.

The materials are qualified in the mobilization retest, such as the thermal conductivity, density, compressive strength or compressive strength of the insulation board.

(3) Material preparation: the composite thermal insulation external formwork is a laminated plate formed by single-sided steel wire mesh plus extruded polystyrene board and its outer side covered with light composite concrete with a thickness of (10 ~ 15) mm.

Install the anchor.

4.

Construction conditions during construction and within 24 hours after construction, the on-site ambient temperature and foundation wall surface temperature shall not be lower than 5 ℃.

6.

This process manual introduces each item according to construction preparation, process flow, key points of construction and quality inspection standards.

Prepare special construction scheme and make disclosure..

Mechanical equipment: electric cutting machine, electric hand drill, grinder, mixer, etc.

(6) Anchor bolt pull-out test: under the standard test conditions, the anchor bolt pull-out strength shall not be less than 0.6MPa, and the insulation board pull-out test: under the standard test conditions, the insulation board pull-out strength shall not be less than 0.1MPa.