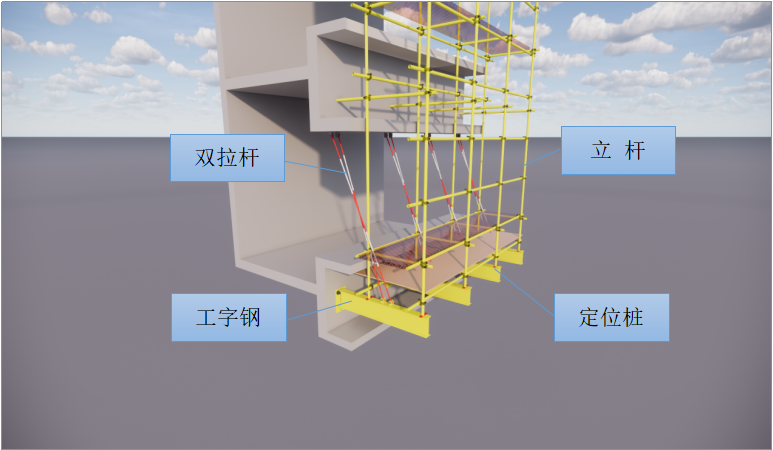

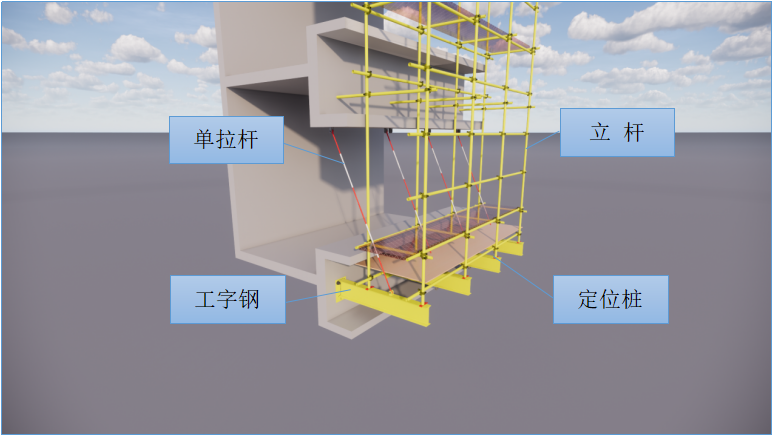

After the mobile positioning pile is in place, install the vertical pole.

After the concrete strength of the main structure of the erection of bolt embedded cantilever beam and scaffold reaches 10MPa, the cantilever beam shall be installed.

Set up the scaffold to the design elevation in turn, and the erection height of each scaffold shall not exceed 20m.

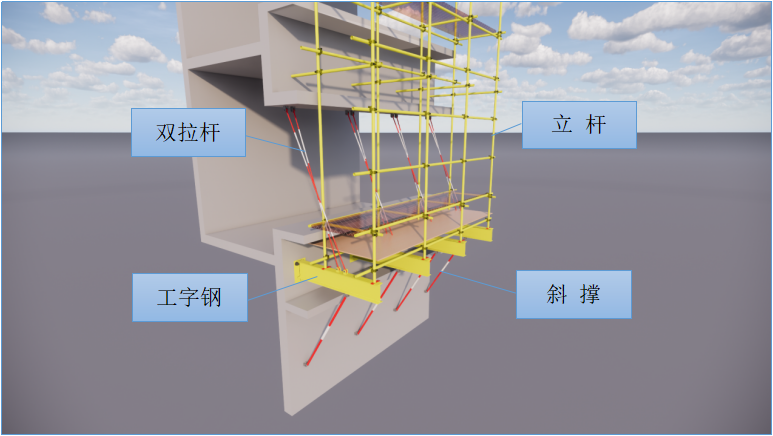

According to the structural characteristics of different positions, the length and structural form of cantilever I-beam are determined.

The new cantilever scaffold has the characteristics of no through wall installation, simple construction, lightweight operation and high reuse rate.

For each cantilever beam embedded with embedded parts, open two round holes on the outer formwork (10cm to 20cm below the concrete pouring and tamping surface), and then temporarily fix it through supporting special screws, Ensure that the embedded parts do not deviate during concrete pouring, and the contact surface between the embedded parts and the formwork is seamless and close, so as to prevent the concrete slurry from penetrating into the embedded parts pipe.

The longitudinal distance of the vertical pole shall not be greater than 1.5m.

Single tie rod: 0.5m < cantilever I-beam length ≤ 1.8m double tie rod: 1.8m < cantilever I-beam length ≤ 2.4m double tie rod + diagonal brace: 2.4m < cantilever I-beam length ≤ 3.0m.

Deepen the design and layout of cantilever beam, and issue relevant construction plans according to the specifications.

While reducing the construction cost, it can effectively ensure the construction quality and reduce the hidden danger of external wall leakage.

New cantilever scaffold..