1、 Introduction to the construction process of diaphragm wall I.

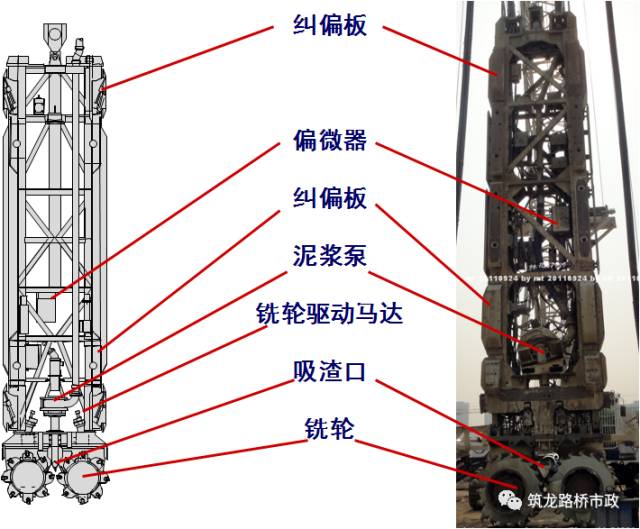

can be excavated; High construction efficiency, fast excavation speed, medium hardness rock can reach 1 ~ 2m3 / h; The grooving accuracy is high, and the verticality can be as high as 1 ‰ ~ 2 ‰; The grooving depth is large, generally up to 60m, and the special model can reach 150m; The equipment has high degree of automation, flexible operation and convenient operation.

2、 Guide wall construction 1.

construction preparation construction road 1.

Depth: at present, the construction speed of conventional equipment is 60-80m.

(generally only used in rock stratum, and also used for backfilling large block stones in some areas) disadvantages: low efficiency.

The former is mostly used in the soil layer with good soil quality, while the latter is mostly used in the soil layer with slightly poor soil quality, and the bottom extends outward to expand the bearing area.

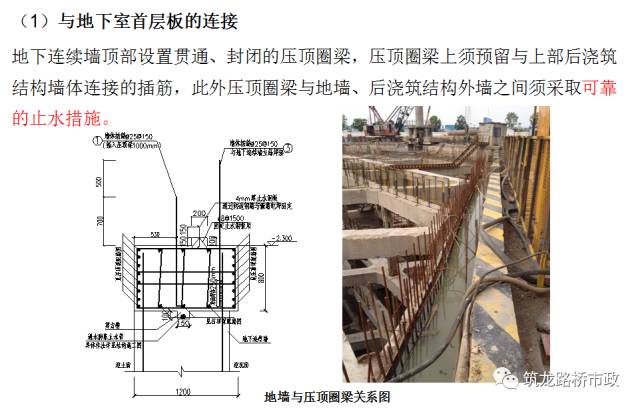

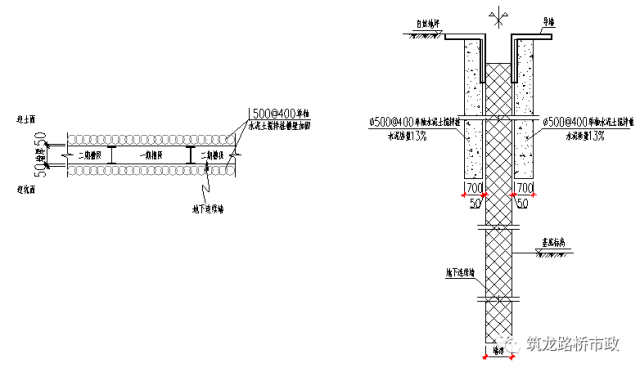

(the depth of the guide wall is mainly based on 200mm into the non filling layer.) 2、 The common structural forms of the guide wall are inverted “L” type and “[” type.

Except for large boulders and bedrock, general overburden can be used.

The grooving accuracy is high.

In addition, it also has the functions of slag carrying, cooling machines and tools and soil cutting lubrication.

Low noise and low vibration; 2.

Work efficiency: the work efficiency of grab is mainly related to depth and soil strength.

At present, slot milling machine and impact drill are only used for rocks with high strength.

Grab bucket has strong trenching capacity and efficient construction; 3.

3.

Division of trench section and excavation unit, and the length of trench section should be 4 ~ 6m..

(desander must be used during mud circulation) IV.

The function of mud: it is mainly used to protect the wall.

Due to the large volume, the mud pit is usually set as semi buried diaphragm wall protection.

Characteristics of impact grooving machine: it has strong adaptability to the stratum, is suitable for general soft soil stratum, and can also use sand gravel, pebble and bedrock.

The road width mainly depends on the traveling width of reinforcement cage hoisting equipment.

The mix proportion of general mud can be selected as follows: quality control of mud: the performance indexes of newly mixed mud and circulating mud shall meet the requirements of the following table.

At the same time, attention should be paid to: 1.

At present, the traveling width of 200t ~ 320t mainstream crawler cranes at home and abroad is 7 ~ 9m, Considering the reserved safety distance and not affecting the construction of concrete pouring, it is recommended that the width of the road is 9 ~ 12m.

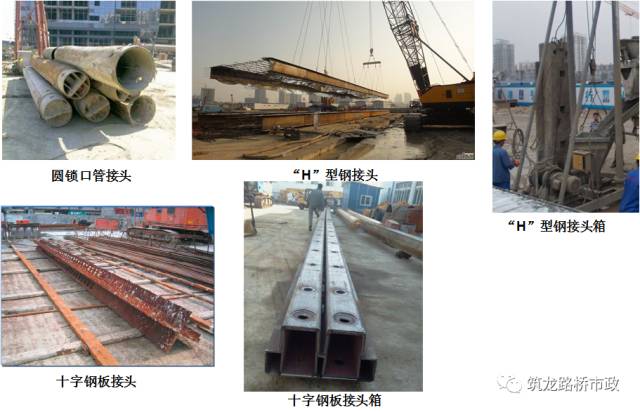

grooving equipment: at present, grab type grooving equipment is commonly used in China (multi head rotation process was adopted in the early 1990s) and milling process or other processes such as impact and rotary excavation are used in rock layer (now high power grab can also directly grab and excavate soft rock).

The mud circulates between the mud pit and the unit tank section through the mud pump and mud pipe.

Mud pit: the mud performance parameters are controlled through the mud pit circulation system to ensure the grooving quality of underground diaphragm wall.

Disadvantages: the excavation depth and when encountering hard layer are limited, which reduces the efficiency of grooving.

Mix proportion of mud: the mix proportion of mud shall be designed and tested according to the geological conditions of the site and the state of groundwater.

The function of 250mm thick Reinforced Road (generally single-layer and two-way) guide wall: measuring datum and grooving guidance; Store mud, stabilize liquid level and maintain the stability of tank wall; Stabilize the upper soil mass to prevent notch collapse; At the same time, it acts as a construction load platform to bear the loads of grooving machinery, reinforcement cage hoisting, etc.

Simple structure and easy operation and maintenance; 4.

The perpendicularity of groove wall reinforcement construction; 2.

Road requirements: according to the site conditions, a circular construction Road (or temporary passing point) shall be set on the outside (or inside) of the foundation pit as far as possible.

When the guide wall meets the unfavorable geology such as flowing soft soil and miscellaneous fill, it is advisable to replace and reinforce the groove wall or adopt deep guide wall.

After the completion of construction, a continuous reinforced concrete wall will be formed underground, which can be used for water interception, seepage prevention, load-bearing, water retaining structure, etc.

About 8-10 hours for 35m deep ground wall (three grabs) and about 20 hours for 60m deep ground wall.

The stability of the hole wall depends on the performance of the mud, and the sediment at the bottom of the hole depends on the sediment content of the mud.

Grab grooving machine features: 1.

The bearing capacity needs to meet the requirements: for large equipment such as trencher, hoisting machinery and concrete transportation used in the construction of diaphragm wall, the foundation bearing capacity is required to be greater than 100kN / m2.

The equipment is cheap.

It is equipped with inclination measurement and deviation correction devices to adjust the verticality of grooving at any time.

The reserve volume of mud should be more than 2 times of the maximum grooving volume planned every day.

The bottom of the guide wall shall be set in the soil layer with high bearing capacity without slurry leakage; The thickness shall not be less than 200mm, and the buried depth of the guide wall shall not be less than 1.5m.

The traveling load of crane is mainly considered.

At present, the equipment sg35 \ 40 \ 46 \ 50 refers to the lifting capacity of grab (35-50 tons), The main machine weight of the grooving machine is about 60-100 tons, the grab is about 20 tons, the grab capacity is about 1m3, and the maximum opening distance of the grab is 2800mm.

(powder jet grouting pile and triaxial mixing pile can be used for groove wall reinforcement.

The whole mud circulation system is composed of mixer, mud storage tank, mud pump, transmission pipe, vibrating screen, sedimentation tank, etc.

Chutes should be set on both sides at the same time to avoid affecting the perpendicularity) III.

Generally, the grounding specific pressure of 300t crawler crane is about 0.08mpa.

Is diaphragm wall a very common construction method in municipal engineering? It will be used in the deep foundation pit engineering of the city.

Conventional practice: 2.

Limitations: the equipment is expensive and the maintenance cost is high; It is not applicable to the formation with large pebbles and boulders; It is sensitive to the falling of iron tools in the formation or the reinforcement existing in the original formation.

The applicable conditions of grab grooving machine: wide adaptability of stratum, such as cohesive soil, sandy soil and gravel soil with n < 40.

Structure of double wheel milling grooving machine advantages of double wheel milling grooving machine: strong adaptability to stratum, and sludge, sand, gravel, pebble, medium hardness rock, etc.

As the equipment currently relies on import, according to statistics, the number of domestic equipment is only about 10, and the equipment cost is high and the maintenance is inconvenient, so it is rarely used.