It can be made of reinforcement with a diameter of 6 ~ 10mm, and its vertical and horizontal spacing shall not be greater than 60mm.

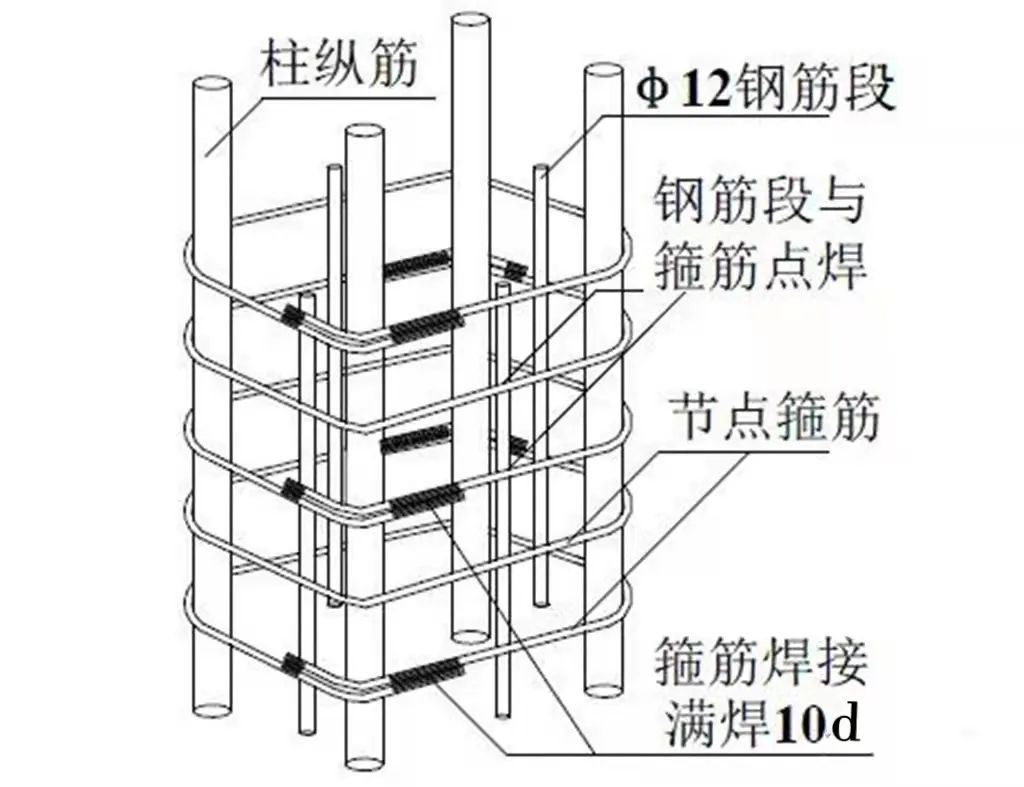

4) If the stirrup is overlapped at 90 degrees, the overlapped part shall be welded, and the weld length of single-sided weld shall not be less than 5D.

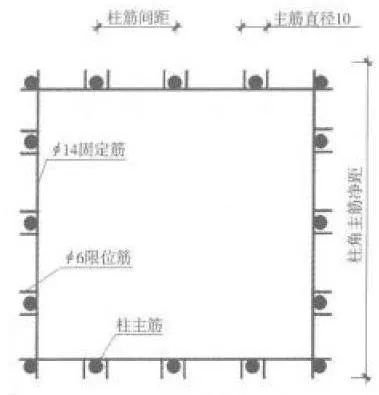

The processing dimension of the column bar positioning card must be processed in strict accordance with the spacing of the column main bars and the diameter of the column main bars, and the allowable deviation of the main bars is ± 5mm.

5.

First set the stirrups on the lap bars protruding from the lower layer, and then erect the column reinforcement (including the connection construction by mechanical connection or electroslag pressure welding).

The horizontal bar inside or outside the vertical bar shall meet the design requirements.

The first stirrup is generally 50mm from the floor.

3.

2.

5) The stirrups at the upper and lower ends of the column shall be densified.

If the main reinforcement of the column is overlapped with plain round reinforcement, the angle hook shall be 45 degrees with the formwork, and the hook of the middle reinforcement shall be 90 degrees with the formwork.

construction process flow of column reinforcement binding: column reinforcement binding → installation of column reinforcement positioning fixture → platform concrete pouring → removal of positioning fixture → column stirrup installation → connection of column main reinforcement → binding of vertical stress reinforcement → drawing of stirrup control line → stirrup binding → key points for operation of protective layer setting: 1.

6.

6) If the reinforcement of the lower column is exposed to the floor, the tool type column hoop should be used to retract it into a column reinforcement diameter 50cm above the floor, so that the reinforcement of the upper column can be overlapped.

The main reinforcement within 500mm above the concrete surface shall be wrapped with plastic film to reduce the pollution of concrete to the main reinforcement.

3) The hook overlap of stirrups shall be staggered along the column vertical bars and bound firmly; When the stirrup is closed everywhere and overlaps with the main reinforcement of the column, the stirrup hook shall be set with a straight section to ensure that the stirrup fits with the main reinforcement; The stirrup shall be staggered from the straight thread sleeve connection area as far as possible.

Draw stirrup spacing line: on the vertical reinforcement of the erected column, draw the stirrup spacing line with chalk according to the drawing requirements.

After the concrete pouring is completed, the plastic film shall be cleaned during calendering, and the concrete around the reinforcement shall be plastered and compacted.

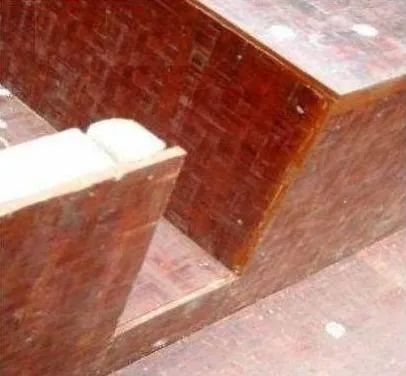

Production of positioning fixture: before column reinforcement binding, make reinforcement fixture according to the spacing of column main reinforcement.

4.

The hook of reinforcement shall face into the concrete.

The lap length of binding joints shall meet the design requirements and regulations.

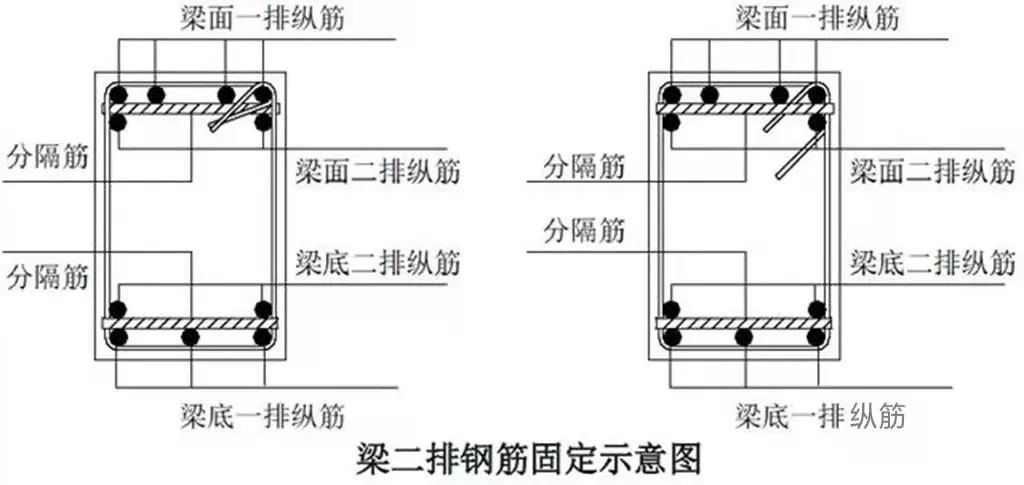

The tie bar or support bar shall be bound between the two rows of reinforcement.

After binding, the positioning fixture shall be installed 20cm above the floor elevation and bound firmly with the main reinforcement.

When the column section changes, the exposed part of the lower column reinforcement must be accurately contracted before binding the beam reinforcement.

Binding of wall reinforcement shall be carried out before formwork installation.

9.

Set column stirrups: calculate the number of stirrups for each column according to the spacing required in the drawing.

If the design requires that the stirrup is provided with tie bars, the tie bars shall be hooked at the joint of the stirrup and the main reinforcement.

Connection of vertical stressed reinforcement: column main reinforcement ≥ Φ 16mm is mechanically connected with straight thread sleeve, Φ 12mm、 Φ 14mm electroslag pressure welding connection or steel bar binding and overlapping connection shall be considered according to the actual situation on site< Φ 12mm is connected by overlapping and binding reinforcement.

When Binding lap connection is adopted, at least 3 stirrups shall be bound within the lap length, and the binding buckle shall be toward the center of the column.

The specification, shape, size, quantity, anchorage length and joint position of the reinforcement must comply with the provisions of the design and construction drawings and specifications.

Bind the vertical bar with the lap bar protruding from the lower layer, draw the horizontal bar grading mark on the vertical bar, bind two horizontal bars at the lower part and chest level for positioning, draw the vertical bar grading mark on the horizontal bar, then bind the rest of the vertical bars, and finally bind the horizontal bars.

After the column reinforcement is bound, it is not allowed to climb.

8.

2.

4.

It is advisable to bind them with buckles.

2) The joints of stirrups (at the overlap of hooks) shall be staggered on the four corner longitudinal reinforcement; The corner of stirrup and the intersection of longitudinal reinforcement shall be fastened (the intersection of the straight part of stirrup and longitudinal reinforcement can be fastened at intervals).

After the main reinforcement positioning card is made, it shall be painted with yellow paint.

3.

The spacing shall be controlled at about 1000mm to ensure the correct thickness of the protective layer of the main reinforcement.

The reinforcement such as frame beam, bracket and column cap shall be placed inside the longitudinal reinforcement of the column.

The end of stirrup shall be bent to 135 °, and the length of straight part shall be 10d.

Positioning fixture for column reinforcement: bind the column reinforcement according to the drawing requirements.

2.

The installation position of the positioning card shall be strictly controlled to avoid being too high and too low, and it is not easy to take out after pouring concrete.

5.

The surface of the positioning card shall be clean and free of rust, defects and oil stains.

Schematic diagram of column bar positioning card example drawing of fabrication of column bar positioning card practice quality requirements within 5000mm of binding column root of frame column: 1.

When the storey height exceeds 4m, the scaffold shall be erected for binding, and measures shall be taken to fix the reinforcement to prevent the column reinforcement framework from being not vertical.

Binding of column stirrups: 1) move the set stirrups upward according to the drawn stirrup position line, and bind them from top to bottom.

Binding of column reinforcement: the reserved column reinforcement on the upper part of the slab shall be corrected according to the reinforcement position line, and the column reinforcement shall be hoisted and bound.

6.

The concealed acceptance of reinforcement shall comply with the code for acceptance of construction quality of concrete structures and other relevant requirements.

2.

When the reinforcement enters the site, samples shall be taken for mechanical property inspection according to the current national standard hot rolled ribbed reinforcement for reinforced concrete, and its quality must meet the provisions of relevant standards.

The stirrup shall be perpendicular to the main reinforcement.

Setting of protective layer: the cushion block of the protective layer shall be bound to the outer skin of the longitudinal reinforcement of the column, and the cement mortar cushion block and plastic card shall be used.

Fixture fixing rib adopts φ 14 reinforcement and spacing reinforcement φ 6 rebar, spacing of spacing rebar is the diameter of column main rebar +10mm.

When binding reinforcement, the binding buckles shall be splayed with each other.

7.

The reinforcement skin shall be bound with cushion blocks or plastic cards..

3.

1.

The length of the densified area and the spacing of stirrups in the densified area shall meet the requirements of the design drawings.

The shear wall reinforcement shall be bound point by point.

construction process flow of shear wall reinforcement binding: erect 2 ~ 4 vertical bars → draw horizontal bar spacing → bind positioning horizontal bars → bind other bars and vertical bars → set reserved holes → operation points of additional bars in reserved holes: 1.

In case of any change, the design change document shall be handled.