During the fabrication and installation of the support, pay attention to whether the specifications of the suspender and section steel used are qualified, so as to ensure that the support can bear the maximum load of the pipeline or equipment.

Controlling the cooperation and coordination between them can save materials, shorten the construction period and ensure quality.

All the mobilized materials must pass the inspection before entering the construction site.

Try to walk 45 when turning or climbing.

All subdivisional works must be constructed in accordance with the drawings, taking into account various factors affecting the construction quality at the construction site, control the quality inspection and construction progress of construction materials, and improve the quality of construction personnel.

Strengthen the technical disclosure, material control, construction process control, mechanical equipment control, construction process quality control, finished product protection, etc.

Controlling each sub project is the foundation of the whole project, so it is particularly important to control each sub project.

2.

The supervisor shall strictly supervise the construction procedure, and complete the insulation construction after the non-seepage test is qualified, the pipeline pressure test is qualified, and the ceiling keel is installed.

The difficulty of HVAC insulation lies in the construction of water system.

If the requirements in the work are not strict, it will cause the installation quality to fail to meet the design and specification requirements and rework..

It is strictly prohibited to use unqualified materials for construction.

The insulation layer of water pipes and air ducts shall be continuous and tight at the places where they pass through the wall, floors and technical joints, and the anti-corrosion of pipes and wooden strips used as cushions shall be qualified.

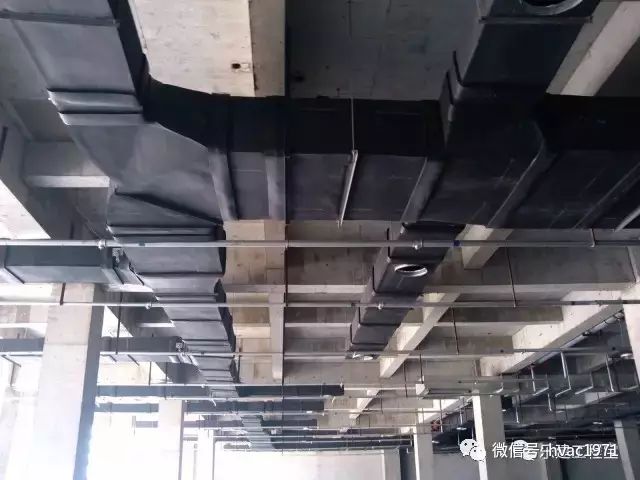

In the process of project construction, the construction of HVAC project is closely related to the construction of civil engineering, electrical, fire protection and other types of work.

Most pipelines and equipment of HVAC project are concealed by ceiling, and there are other construction in the subsequent process, such as ceiling construction.

The insulation construction shall ensure that all parts are tightly closed without leakage joints or points.

2.

4.

After the ceiling construction, the supervisor shall recheck the concealed works of the ceiling and require the construction unit to repair the damaged parts in time.

Pay attention to the special requirements of purification air conditioning system.

It shall be installed as straight as possible to avoid excessive bends.

Strengthen the quality of construction personnel and improve their professional skills.

The project acceptance must meet the relevant provisions of the code for acceptance of construction quality of building water supply, drainage and heating engineering, and there must be no potential quality hazards.

Those who fail to pass the quality inspection form and certificate shall not enter the site.

If some holes are not blocked properly, there will be quality problems of HVAC engineering, such as air leakage, insufficient fresh air, exhaust gas unable to be emptied and ventilation unable to be carried out.

participate in the “courtesy of newcomers” and draw vouchers of 120 yuan and 60 yuan for permanent members, 100% of which will win the prize! The installation quality of HVAC engineering is directly related to the normal use function of buildings.

Precautions for HVAC installation: check whether the reserved works are in place, mainly whether the position of the reserved holes is accurate, whether the size meets the design and process requirements, whether the embedded parts of equipment and foundation are correct, and whether the manufacturing materials are qualified.

Pay attention to the official account (id:mepbbs) of electromechanical world politely, and the dialog box reply: pay attention, 1 Send word version of electromechanical installation disclosure; 2.

Specific measures for HVAC engineering construction 1.

Construction personnel must work with certificates, and no inexperienced team is allowed to enter the site for construction.

to the construction personnel.

3.

Therefore, first of all, technical safety disclosure should be made to the construction teams to let them understand what to do and how to do it.

They are less specified in various specifications, but the specific location is set by the designer according to needs.

The specifications and dimensions of commonly used metal air ducts meet the design requirements.

3.

Whether it is the materials purchased by the construction unit or the materials supplied by Party A, the professional and technical personnel shall conduct a comprehensive and strict inspection on their specifications, models and quality.

Quality control of anti-corrosion and thermal insulation works.

Angle to reduce air retention at the elbow.

The design and construction units shall be strictly required to carry out technical disclosure for different types of work at different stages.

The project acceptance must comply with the specifications.

2.

The reinforcement of round air duct, rectangular air duct and irregular air duct and the fabrication of pipe fittings must comply with the specifications.

It is required that all test reports must meet the national technical standards and design requirements.

HVAC engineering is the final work of the whole construction project, so the final project must be meticulous.

It is required that the thermal insulation material shall be pasted firmly, the interface shall be tight, and the gas and moisture barrier shall be tight.

The fan coil valve and filter shall be installed within the ponding pan as far as possible to facilitate drainage during maintenance.

1、 Strengthen the preliminary preparation, get familiar with the drawings, and clarify the design intent, structural features, quality requirements and relevant precautions in the drawings to ensure that the construction is carried out according to the drawings.

The undercut and flange connection of air duct shall comply with the specification.

If quality problems are found, they must be handled as soon as possible and seriously to ensure construction quality.

Establish a sound construction system.

For example, the insulation layer of valves that are prone to quality problems shall have sufficient coverage.

Strengthen the control in the installation stage of the project, and inspect all the mobilized materials.

The fabrication of air duct shall meet the design requirements.

However, most of the front-line workers in the construction industry today are migrant workers, whose professional knowledge and technical level are uneven, and the technical content of HVAC engineering is relatively high.

The insulation materials shall be closely bonded with the skid, and the size of the skid shall match the pore size of the pipeline, so as to strictly prevent construction quality accidents caused by condensate dripping.

The installation of air duct shall be the shortest and most economical.

Support fabrication and installation supports play the role of fixing and supporting pipes in the HVAC system.

Construction personnel are the soul of the quality realization of HVAC engineering.

The valve shall be installed in the same direction as the water flow.

Reasonably arrange the construction progress to ensure the construction quality and safety.

Reserved hole plugging inspection many reserved holes through the wall or floor will be left after the construction of HVAC pipes.

Control the quality inspection of construction materials.

The supervisor shall check the reserved sealing.

Key construction points of HVAC Engineering 1.

Condensate drainage pipe shall be a separate system and shall not be shared with other drainage pipes.

Coordinate with relevant departments to deal with hidden dangers in time.