When passing through the cast-in-place concrete column horizontally, the structural strength of the column will be weakened.

Pipe grounding pipe and pipe, pipe and box shall be electrically connected.

The piping and the concrete surface shall not be less than 15mm, otherwise the floor slab is prone to cracks.

K.

B.

It shall not be bound with the main reinforcement.

If the lamp position is not a slab joint, the hole can be cut in the slab hole to bury the box (using ordinary lamp head box), but the slab rib cannot be damaged.

On the concrete slab, prestressed hollow slab, cast-in-place concrete floor slab and precast thin concrete floor slab, the position and size of the lamp cap box shall be marked.

F.

50.

When using the wooden formwork, the lamp box can be nailed to the formwork with nails, and the pipe shall be kept at a certain distance from the reinforcement and bound tightly.

A.

Laying of pipes in the hollow brick partition wall of frame structure: when the pipes are laid horizontally in the hollow brick wall, a line of ordinary bricks can be used in the piping layer, or a section of concrete can be poured to protect the pipes.

3、 The box and box holes can be reserved for the box and box, and the box and box can be embedded stably by digging holes, and then connected with short pipes.

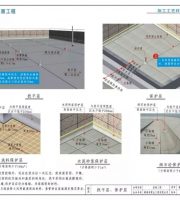

1、 Snap line positioning according to the requirements of design I drawings, determine the position of boxes and boxes at brick walls, large formwork concrete walls, sliding formwork concrete walls, wood formwork concrete walls, composite formwork concrete walls, etc.

When the steel pipe (thickness not less than 2mm) is connected by screw thread, the round steel with diameter not less than 6mm shall be used for welding.

C.

Laying of pipes in the cast-in-place concrete column: the pipes shall be laid in the middle of the column and bound with the main reinforcement or stirrup every LM.

When piping in the floor (roof) coke slag cushion (other insulation layers), the surrounding of the pipeline shall be protected with cement mortar with a thickness of not less than 50mm before the cushion construction to prevent the pipeline from mechanical damage.

The light box, switch box and socket box on the inner wall of the cast-in-place rod concrete column shall be laid in the middle of the column.

The outer diameter of the pipes shall not exceed 1/3 of the thickness of the concrete slab.

H.

J.

Laying of pipes in the ground: generally, the pipes are laid in the composite soil cushion, and the cushion is compacted and leveled before laying.

E.

The lamp position box should also be buried in the slab joint as far as possible (DF type).

When laying pipes in balcony and awning, it should be carried out after the bottom formwork is erected and before the reinforcement is bound.

4、 Steel pipes, especially power lines, are often used for the piping inside the concrete frame of cast-in-place rods for concealed pipe laying.

Laying of pipes in the floor (roof) cushion (post cast layer): the thickness of the cushion (post cast layer) shall be able to protect the pipes, the minimum thickness of the protective layer of the pipes shall not be less than 15mm, and the uneven parts of the floor (roof) shall be leveled.

It shall be ensured that the main reinforcement is surrounded by concrete, so that the mechanical strength of the beam can be guaranteed.

Laying of pipes in the cast-in-place concrete floor slab: after the formwork of the cast-in-place concrete floor slab is erected, before the reinforcement is placed, the electrician shall snap a cross line according to the edges of the walls and beams around the room to determine the accurate position of the lamp position.

The pipes in the wall of the cast-in-place rod shall be laid between two layers of reinforcement, and the pipes and reinforcement shall be bound firmly.

Rigid PVC pipes with high strength can be used for lighting lines and weak current systems, and steel pipe protection shall be provided at important parts of the structure.

It shall be laid near the middle position of the beam, at least 50mm away from the upper part of the beam bottom reinforcement.

Laying of pipes in balcony and awning plate: the stress of cast-in-place concrete balcony and awning plate is that the upper part is under tension and the lower part is under pressure, so the reinforcement mesh is set in the part.

2、 Cold snuggling method and hot feeding method can be used to process pipe bending and prefabricate pipe bending.

1.

The binding point at the box inlet shall not be greater than 0.3m.

Pipe laying in the cast-in-place concrete wall: the pipe box shall be connected in the cast-in-place concrete wall first, and the box (box) laid in the wall shall be in the reinforcement grid.

Pipe laying of aerated concrete block partition wall of frame structure: the pipe laying of aerated concrete block partition wall, except for the distribution box, shall not cooperate with the wall laying and embedding, and the wire boxes and pipes of other appliances shall be grooved and laid after the wall laying.

Galvanized steel pipes can not be welded, but can be crimped with copper wires of not less than 4m ㎡, with special grounding crimping clips..

When the steel pipe is bent, the flattening degree shall not be greater than 10% of the outer diameter of the pipe The bending angle should not be less than 90 °.

D.

The exposed section shall be protected by steel pipes.

First, the pipe shall be connected with the box, and the box shall be tightly blocked with waste paper wrapped with plastic film or plastic film wrapped with sawdust or hemp rope, so as to avoid mortar penetration during pouring.

For the pipes laid in the ground, the height of the pipe orifice above the ground shall not be less than 200mm, and shall be vertical to the ground.

The method is the same as that of open application.

The buried end of the steel pipes shall be sawn into a 30-45 degree inclined mouth to increase the underground fixed length.

G.

Pipe laying in cast-in-place concrete beam: when the pipe needs to cross the beam, the position of crossing the beam shall be some distance from the beam end, and it shall pass through the middle of the beam; When the pipe needs to vertically cross the beam, it is better to cross it near 1/3 of the clear span of the beam, where the stress on the beam is the smallest; When the pipe is laid horizontally in the beam, the plastic pipe shall be laid at a certain distance from the main reinforcement.

The steel pipe shall be used as the casing, leaving the end of the column as far as possible.

Pipe laying of precast hollow floor slab: the pipes of precast hollow floor slab can be laid in the slab joint or slab hole in a concealed manner, and cannot be laid horizontally.

The binding point shall be no more than 1m away, and a point shall be bound near the box.

When the hollow bricks are laid horizontally, they can also pass through the hollow hole of the hollow bricks.

The outer end of the sleeve shall be tightly blocked, closely attached to the formwork and fixed, and directly poured into the concrete.

When piping leads out of the column, in order not to stretch out the formwork, a sleeve shall be sleeved at the pipe orifice and glued.

The pipelines shall be laid in a shortcut without being parallel and vertical to each other.

The pipe shall be connected with the lamp position box, the box shall be blocked tightly and fixed firmly with the formwork, and the pipe shall be padded on the formwork at least 15mm high.

After the floor bottom reinforcement is bound and padded, the piping shall be carried out before the gluten (some called cover iron) is bound.

The pipeline shall be laid between the two layers of reinforcement, and the gluten shall be bound after the piping is completed.

When the pipeline passes through the deformation joint (settlement joint) of the building, the junction boxes shall be buried on both sides as compensation devices.