The upper opening of the fixing clip on the support cannot be closed with the angle steel of the support.

The turning is smooth without sharp water chestnut.

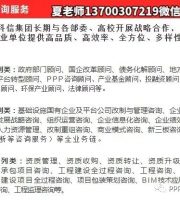

2) It complies with the provisions of gb50057 code for design of lightning protection of buildings, “when the non-conductive roof object that is not within the protection range of the lightning arrester does not protrude more than 0.5m above the plane formed by the lightning arrester, it is not required to add additional protective measures of the lightning arrester.” Non metallic pipes shall be provided with air termination separately.

2.

Construction specification: the construction of roof lightning strip is in accordance with gb50303 code for acceptance of construction quality of building electrical engineering: the lightning rod and lightning strip should be in the correct position, the welding seam fixed by welding should be full without omission, the anti loose parts such as caps fixed by bolts should be complete, and the anti-corrosion paint applied on the welding part should be complete.

Key points of construction control of lightning strip 1.

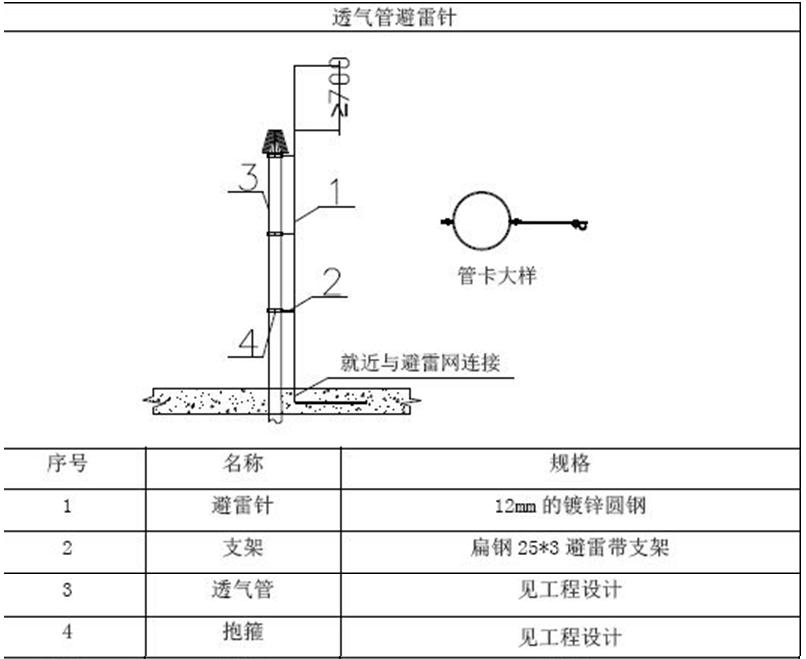

The spacing of lightning strip supports in straight-line section shall be evenly distributed, and the spacing shall be controlled within 0.5-1.5m, which should generally be determined as 1m.

Snap the line smoothly and without distortion.

The height from the finished surface of the building is the same, 150mm.

The installation of lightning strip downlead and support frame should be planned to be set in the magnetic slice joint or when the lightning strip passes through the expansion joint in the magnetic slice, the “Ω” bend downlead should be painted with green / yellow marks to be eye-catching, and the downlead signboard should be made uniformly.

4.

② Support installation 1.

Construct lightning protection and grounding downlead in strict accordance with lightning protection and grounding plan.

If the size of isolated metal objects on the roof that are not protected by lightning arresters does not exceed the following values, additional protective measures may not be required: they are not more than 0.3m higher than the roof plane, the total area of the upper surface does not exceed 1.0 ㎡ and the length of the upper surface does not exceed 2.0m “, they shall be connected with the lightning protection device.

3.

I.

3 common quality problems 1.

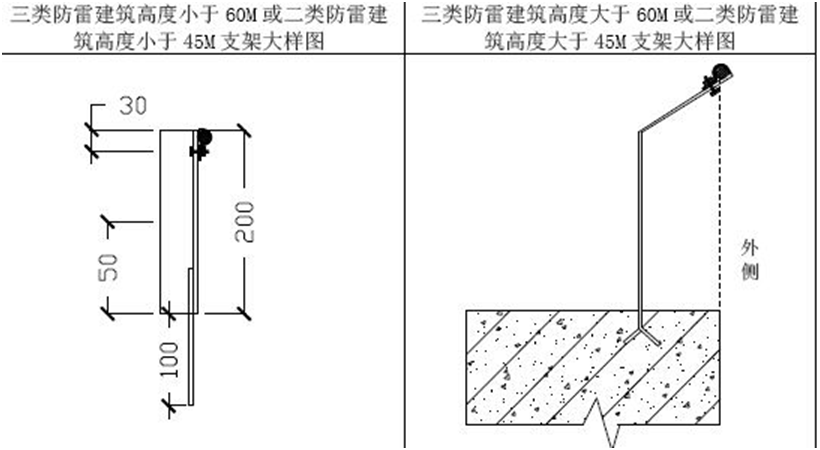

For the prevention of direct lightning strike on the roof of high-rise buildings, lightning protection belts should be set along the periphery of the roof, and their installation positions slightly protrude from the outer edge of the roof, as shown in the figure for special cases (see Atlas 03d501-3p54).

II.

The lightning strip shall be smooth and straight, the spacing between the fixed point supports shall be uniform and the fixation shall be reliable, and each support shall be able to have a vertical tension greater than 49n (5kg).

3.

The galvanized round steel lightning strip is connected by single Z-shaped lap (it is recommended to use self-made mold), and the lap length is 6 times the diameter of the round steel, and it is overlapped up and down.

Strictly control the construction materials, and the materials meet the drawings.

Roof lightning strip is a lightning receiving device that bears direct lightning strike on buildings and introduces strong lightning current to the earth.

2.

2.

5.

3.

The paint must be antirust paint, and the color is generally silver.

The lightning strip shall be straight and consistent in height, and the deviation of flatness per 2m inspection section shall not be greater than 3/1000.

2.

The lap length of downlead and lightning strip shall not be less than 6D (d galvanized round steel diameter), and welding shall be carried out on both sides.

The spacing of support locating points is uniform.

As an important part of lightning protection engineering, its design and construction are very important.

The spacing between fixed supports shall be ≤ 1000mm, and the spacing between corner supports shall be ≤ 500mm.

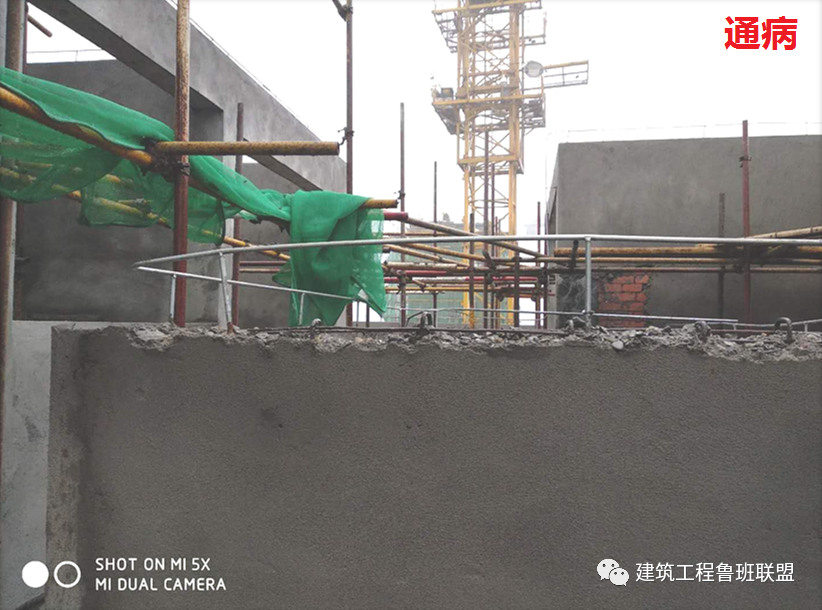

The height of lightning strip is inconsistent, and the bending is not smooth and straight.

When there are no requirements in the design, the spacing of supporting parts shall meet the horizontal straight-line part of 0.5-1.5m; The bending part is 0.3-0.5m.

It is smooth and straight, beautiful and without distortion.

Materials do not meet the requirements, and threaded steel is used to replace galvanized round steel.

Construction process of lightning strip ① setting out and positioning 1.

3.

2.

The weld is full, without slag inclusion, undercut, cracks, pores, etc.

⑤ Welding antirust treatment 1.

Then, how can the roof lightning strip be standardized? This article is summarized for your reference and exchange.

The specific spacing shall be adjusted appropriately.

The lightning strip shall be smooth and straight, the spacing between the fixed point supports shall be uniform and the fixation shall be reliable, and each support shall be able to bear a vertical tension greater than 49n (5kg).

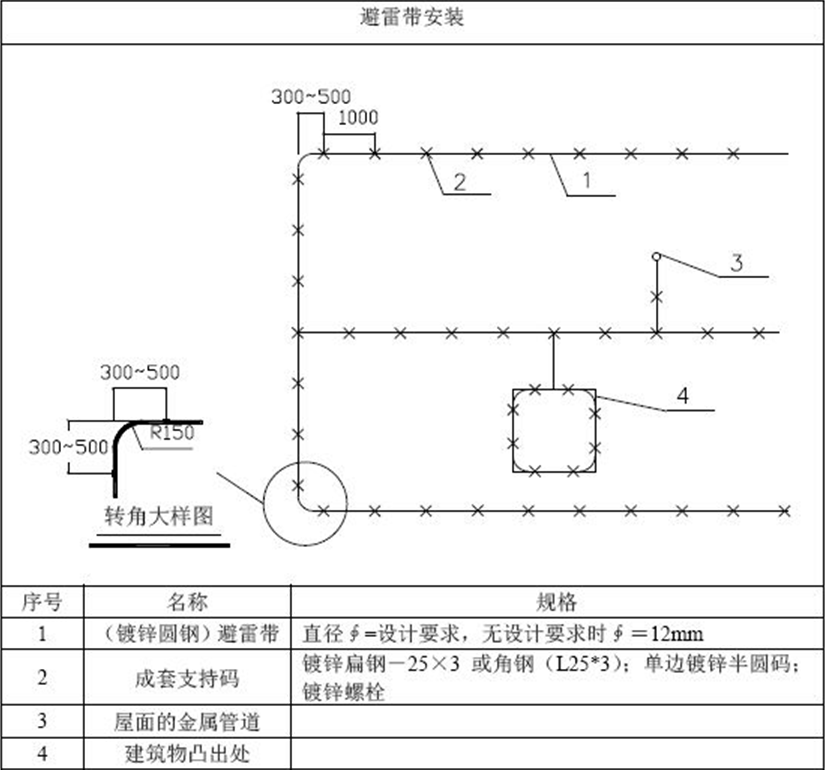

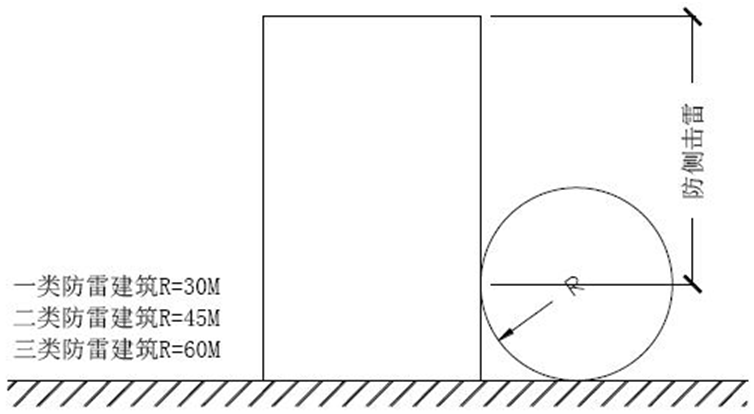

See the description of the protected area in the figure below for details.

3.

3) For high-rise buildings, if the first-class buildings exceed 30m, the second-class buildings exceed 45m, and the third-class buildings exceed 60m, side lightning protection should be done.

③ Installation of lightning strip 1.

2 key points of process: galvanized angle steel (l25*3) or galvanized flat steel (-25) shall be used for lightning strip support in actual construction × 3) Special clips or wire rope clips can be used for clamp installation.

1.

The lightning strip laid along the periphery of the roof with the height of the second type of lightning protection building more than 45m shall be set on the outer surface of the outer wall or the vertical surface of the eaves, and can also be set outside the outer surface of the outer wall or the vertical surface of the eaves.

④ Lead down spot welding 1.

The lightning strip is 150-200mm higher than the parapet or the finished surface of the roof.

design code 1 is based on the design of roof lightning strip, gb50057 code for design of lightning protection of buildings, and the lightning protection measures of class I, II and III lightning protection buildings are implemented in accordance with the provisions of articles 4.2, 4.3 and 4.4 respectively.

The three construction examples of lightning strip stereotyped support frame are the construction control points and process flow of lightning strip summarized by the country garden project department based on the engineering examples, for construction guidance, you can refer to and implement.

Before painting antirust paint, the welding slag and coating shall be cleaned; If there is rust, remove the rust to the primary color of round steel.

The hole shall be positioned in the middle without collapse.

The lap length of lightning strip and lightning strip shall not be less than 6D (d galvanized round steel diameter), and welding shall be carried out on both sides.

The lap length of lightning strip (Network) and downlead meets the specification requirements, and the welding quality meets the requirements.

2.

The spacing is uniform, the horizontal spacing is not more than 1000mm, the vertical spacing is not more than 1500mm, and the spacing at turns is 300-500mm.

3 precautions 1) the metal pipes protruding from the roof shall comply with the provisions of gb50057 “code for design of lightning protection of buildings”.

2.

Firm without looseness, with consistent height.

4.

3.

The antirust paint shall be applied evenly without omission.

Sharp corners are formed at the corners, which is easy to discharge at the tips..

The semicircular surface of expansion compensation is vertical or parallel to the sky.

Accurate positioning, vertical without inclination.

Under special circumstances, metal pipes and accessories in accordance with gb50057 code for design of lightning protection of buildings need to be provided with separate lightning receiving devices.

2.

The spacing of supports is inconsistent, and the spacing at turns is greater than 500mm.

3.

See the following figure for the specific method.