Mixing: aggregate, cement, water and admixture shall be measured by weight first.

6.

In recent years, the types of concrete have become more and more.

The water sealing time should not be less than 5 days.

The cement, ceramsite, sand, etc.

For the ground with slope requirements, after finding out the high and low points according to the slope required by the design, draw a small line and then plaster the slope pier, so as to control the surface elevation of the cushion.

Ceramsite concrete construction technology is one of the problems we need to understand in our daily life.

Ceramsite concrete construction technology? 1、 Construction preparation 1.

Almost every building will use ceramsite concrete, so the construction technology of ceramsite concrete is very important, and the acceptance standard of ceramsite concrete is also what we need to know.

Construction technology is very important and directly related to the construction quality, so every step should not be sloppy, no matter which step is missing, it may cause quality problems.

2.

Materials and main machines and tools ceramsite shale ceramsite: the particle size is 5 ~ 30mm, the loose density is 500 ~ 700kg / m3, the water absorption is 3.5% ~ 5% (30mm in dry state), the immature flakes should be less than 10% ~ 15%, and the content of powder and particles with particle size less than 5mm should be less than 5%.

Admixtures: the dosage must be determined through tests and implemented in accordance with relevant technical regulations.

3.

The ceramsite concrete cushion and the base must be firmly bonded, and there must be no hollowing, surface looseness, cracks and other defects.

Clay ceramsite: the particle size is 5-30mm, the loose density is 580-680kg / m3, the water absorption is 8.3% – 10% (1h in dry state), and the content of powder and particle size less than 5mm should be less than 5%.

5.

Use a large aperture sieve (the sieve hole is 30mm) for the first time, and a small aperture sieve (the sieve hole is 5mm) for the second time, so that the 5mm particle size content is controlled within the requirements of no more than 5%.

Ceramsite concrete construction technology has now become particularly rapid progress.

Laying, vibrating or rolling: the thickness of ceramsite concrete cushion shall not be less than 60mm, and the strength grade shall not be less than C10.

Sand: medium sand or coarse sand, and the silt content shall not be greater than 5% when the concrete strength grade is ≥ C10 ~ C30.

Cement: generally, 325 and 425 slag Portland cement or ordinary portland cement are used.

Main machines and tools: forced concrete mixer or self falling concrete mixer, scale, narrow trolley, admixture, dilution container, flat vibrator, spade, clapper, iron roller, small hammer, chisel, wire brush, brush, half bucket, small bucket, rubber water pipe, wood float, small kettle, 2 ~ 3M wooden bar, 5mm and 30mm aperture sieve.

I hope Xiaobian’s introduction can help you…

Before pouring the cushion, water the haydite pile evenly, and seal the haydite thoroughly.

4.

Fly ash ceramsite: the particle size is 5 ~ 15mm, the density is 630 ~ 700kg / m3, the water absorption is 16% – 17% (1h in dry state), and the content of particles with particle size less than 5mm or greater than 15mm should not be greater than 5%.

5.

Now let’s take a look at the relevant knowledge of ceramsite concrete.

Base course treatment: before pouring the ceramsite concrete cushion, treat the base course of the concrete floor, remove the loose concrete and mortar bonded to the base course with a chisel, brush off the cement slurry with a steel wire brush, and then sweep it with a broom.

Since the ceramsite is subject to water tightness treatment in advance, the specific water consumption is adjusted according to the moisture content of the ceramsite before mixing.

The allowable deviation of aggregate measurement shall be less than ± 3%, and the allowable deviation of cement, water and admixture measurement shall be less than ± 2%.

3.

If the room is large, the fine aggregate concrete leveling pier can be plastered at an interval of about 2m.

2.

6.

Inclusions or clay blocks shall not be mixed.

Now the continuous progress of high technology has also brought progress in all aspects.

4.

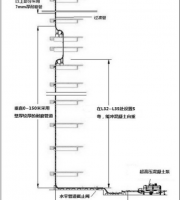

Base course treatment → finding the elevation and snapping the horizontal control line → ceramsite screening and water tightness → mixing → laying ceramsite concrete → curing 2.

2、 Operation process 1.

The material, strength and compactness of ceramsite concrete cushion must meet the requirements of design and construction specifications.

Ceramsite concrete acceptance standard? 1.

The acceptance standard of ceramsite concrete also needs to be understood, so that the quality can be guaranteed.

There are many small steps in construction.

Sieving and water tightness of ceramsite: in order to remove sundries and fine powder in ceramsite, ceramsite should be sieved twice after entering the site.

3.

Find the elevation and snap the horizontal control line: measure the cushion elevation downward according to the + 50cm horizontal elevation line on the wall, and snap it on the surrounding walls if possible.

used for ceramsite concrete cushion must meet the design requirements and the provisions of construction acceptance specifications.