Through investigation and analysis, the main factors affecting the quality of stairs are insufficient stiffness and stability at the joints of stair formwork, and formwork running, formwork expansion and distortion are easy to occur in the pouring process.

Node formwork node reinforcement method drawing countermeasure implementation and on-site disclosure (1) drawing and review, at the same time, the production personnel should be familiar with the drawings, dimensions, appearance, style, steps, and carry out technical disclosure to the on-site operators.

(2) The verticality of the stair step formwork is poor, and the internal and external corners are not square.

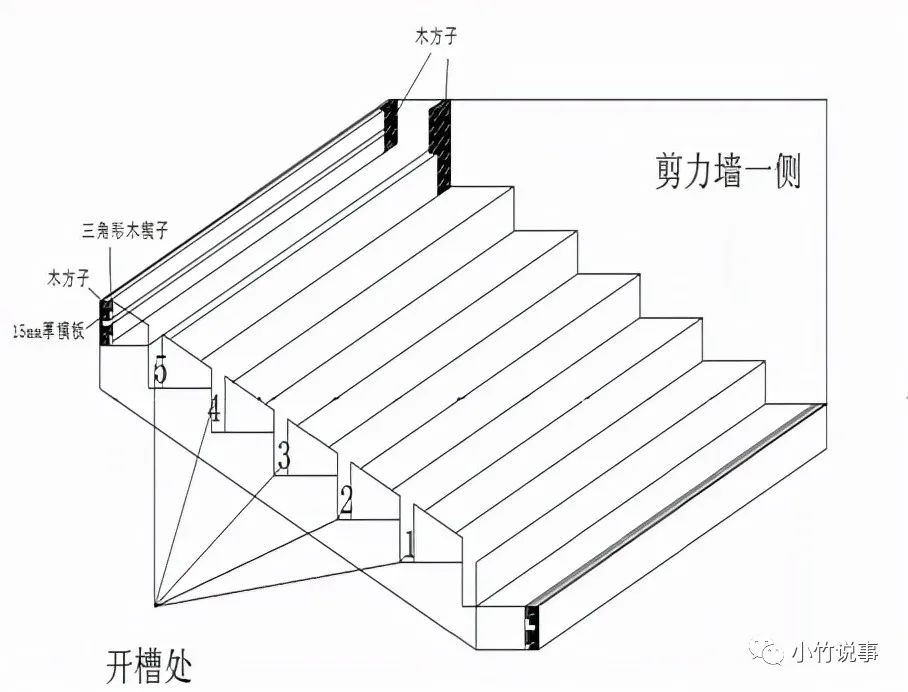

(2) 15mm thick multi-layer plate is selected as the material, and the formwork is processed and installed according to the size of the construction drawing.

The stiffness at the joint is difficult to guarantee.

After removing the formwork, there is no mold running and expansion, and there is no distortion.

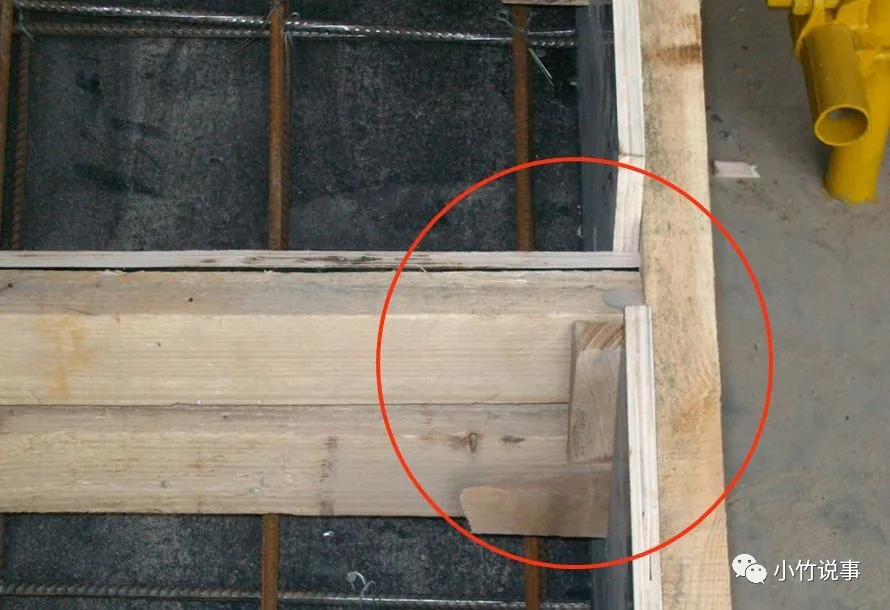

Improvement measures for stair formwork according to the main factors of stair quality, the original reinforcement method of stairs is improved, and the side formwork is slotted: the side formwork of stairs is slotted, and the side formwork is reinforced with wooden wedges and nails.

(3) The slotting at the joint is reinforced with wooden wedges, which increases its stiffness and stability, and effectively avoids the problems of formwork running, formwork expansion and distortion in the pouring process.

What should we start from when we just enter the cost industry?..

Through such an improvement on the traditional formwork support method of stair steps, the construction quality and efficiency of stairs are generally improved: (1) after the formwork removal of stair steps, the edges and corners are straight, the internal and external corners are square, the size deviation is small, and the perceived quality is beautiful.

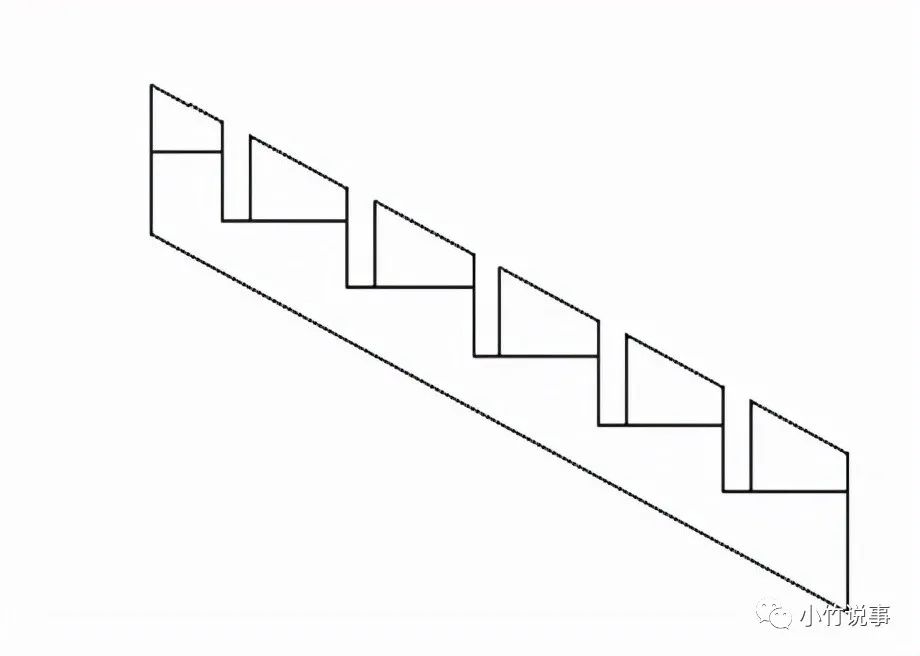

Common problems of stair step quality a detailed investigation and analysis of the stair step formwork support and the appearance dimension deviation after formwork removal at the construction site of residential projects can be found as follows: (1) the section dimension deviation of adjacent stair steps is large, and the phenomenon of formwork running and formwork expansion is serious, which affects the overall appearance quality and the construction of later projects.

Strengthening with wooden wedges can enhance its rigidity and stability, flexible installation and removal, simple operation, and greatly save operation difficulty and time.

Comparison of the effects before and after the improvement: improve the formwork support method of the front stair step: improve the effect after the formwork removal of the front stair: the step is distorted, the section size deviation is large, and the appearance quality is poor.

The “crooked brain” of the budgeter makes the completion settlement faster.

During the process, follow-up inspection and strict control of construction quality are carried out.

(2) After the stair step formwork is removed, there is no phenomenon of mold running and expansion, and there is no need to shave before the next process, which saves the cost of manual shaving and avoids the waste of materials.

(3) Support and reinforce the formwork on site, and check the cross-section size of the step, whether it is twisted, and whether the reinforcement at the node is firm.

The actual effect of the improved stair: after the formwork removal, the edges and corners are straight, the internal and external corners are square, the size deviation is small, and the appearance quality is beautiful.

In addition to the tedious first formwork erection, this method is generally simple, easy to operate and has strong stability, which is worthy of reference.

Therefore, in the case of a residential building project of Shanxi No.1 Construction Co., Ltd., the project department improved the technology based on the original formwork reinforcement method, and used the slotted formwork method to improve the construction quality of stair steps.

In the construction of building engineering, the cast-in-place stair step is prone to the construction quality problems such as the internal and external corners are not square and the verticality is poor due to the improper formwork erection method.

QQ group 925078799, password? How can qq2300665262 add group to improve the level of project cost audit? Do you make the difference between the four grades of project manager a, B, C and D? The difference between the first construction and the second construction.

The actual monitoring shows that the installation speed is fast, the nodes are firm, and the overall stability is good.

There is no need to deal with it before the next process, which saves the cost of manual shaving and avoids the waste of materials.

(4) The installation and removal are flexible, which greatly saves the operation time and difficulty.

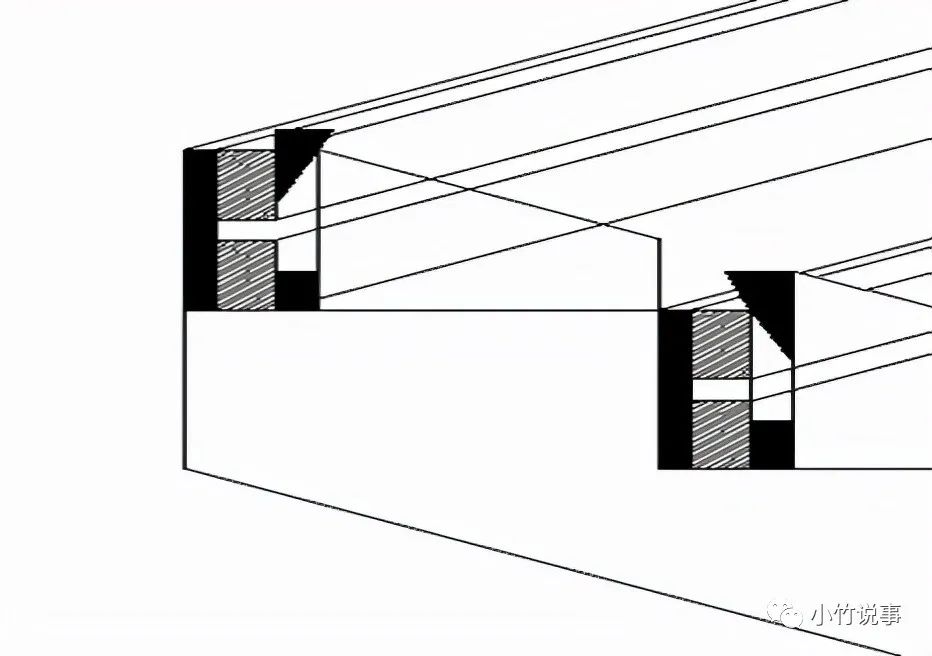

Detailed nodes of slotting formwork: properly increase the spacing of slotting, and fix it alternately with wooden wedges, so as to avoid the loosening and tilting of the stair side formwork during the pouring process.

(3) The formwork erection process is cumbersome and difficult to operate.