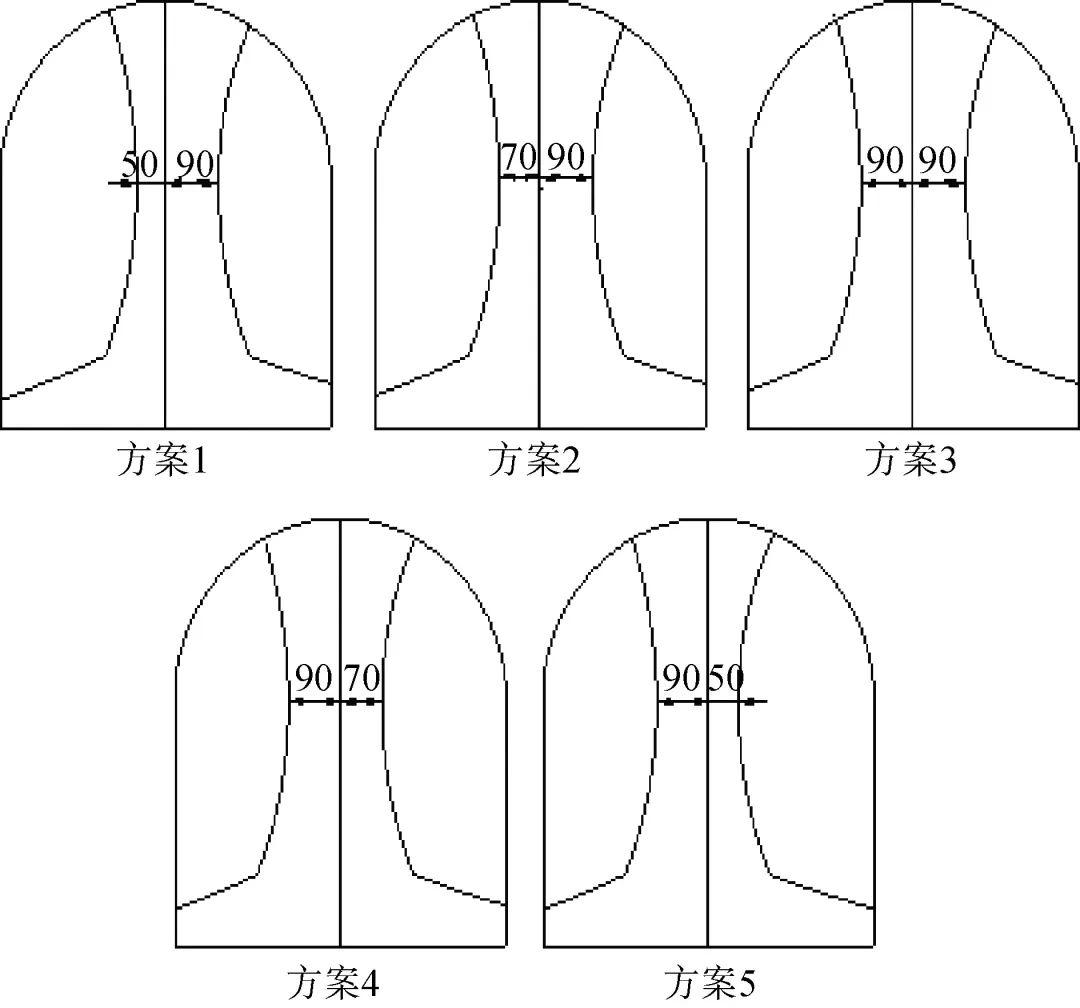

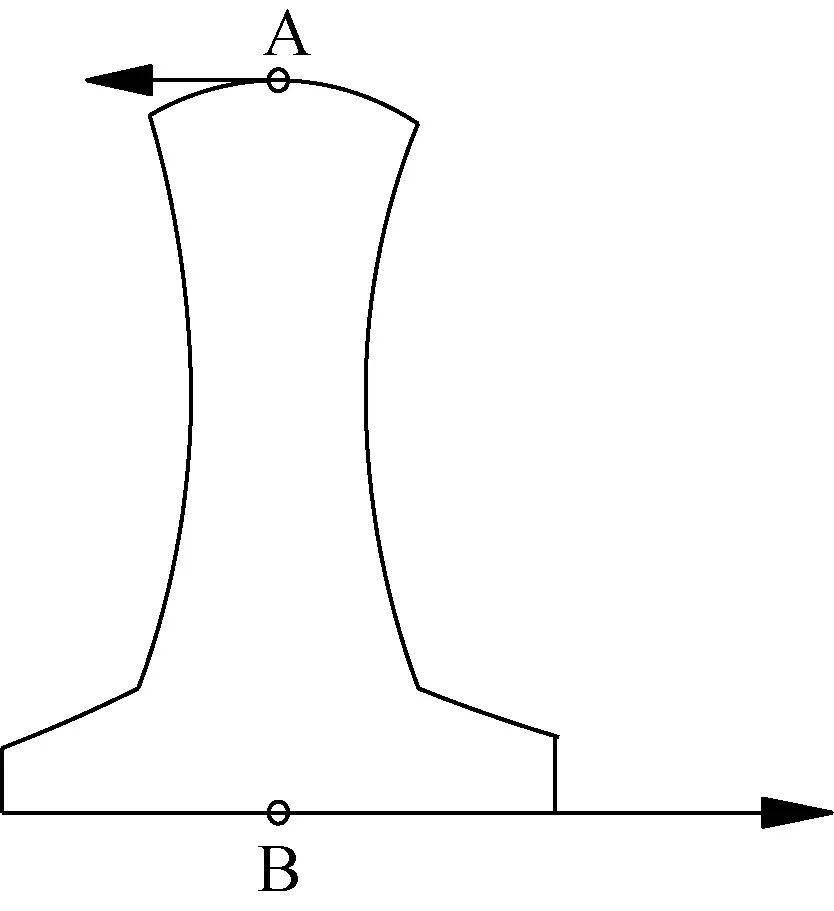

The results show that in asymmetric multi arch tunnels (left large-diameter tunnel and right small-diameter tunnel), the middle partition wall will shift to the large-diameter tunnel and deflect counterclockwise; Symmetrical with the center line of the middle pilot tunnel, reduce the thickness of the middle wall on the side of the small tunnel diameter tunnel, so that when the thickness of the middle wall on the side of the small tunnel diameter tunnel is less than the thickness of the middle wall on the side of the large tunnel diameter tunnel, the settlement of the vault of the left and right tunnels is reduced, the vertical displacement at the lower corner of the middle wall, the top of the center line of the middle wall and the horizontal displacement at the midpoint of the bottom of the middle wall are reduced, and the upper corner of the middle wall is stressed better, the overall deflection amplitude is smaller, and the stability is higher, However, the overall thickness reduction of the asymmetric middle partition wall should be appropriate.

Its deformation and stress during the construction process are very complex, and its stability directly determines the structural safety during the construction period, and also affects the operation safety of the tunnel in the later stage.

However, the above research mainly focuses on the analysis of surrounding rock stress and displacement of asymmetric tunnel excavation, the optimization of construction method and excavation sequence, the mechanical analysis of middle wall construction, and the design location of tunnels with large and small diameters.

[2,3] studied the bearing characteristics of the compound curved middle wall of the multi arch tunnel during the tunnel excavation and the stress change law of the middle wall during the construction.

There is less research on the stability of asymmetric middle wall of asymmetric multi arch tunnel.

Wu Mengjun et al.

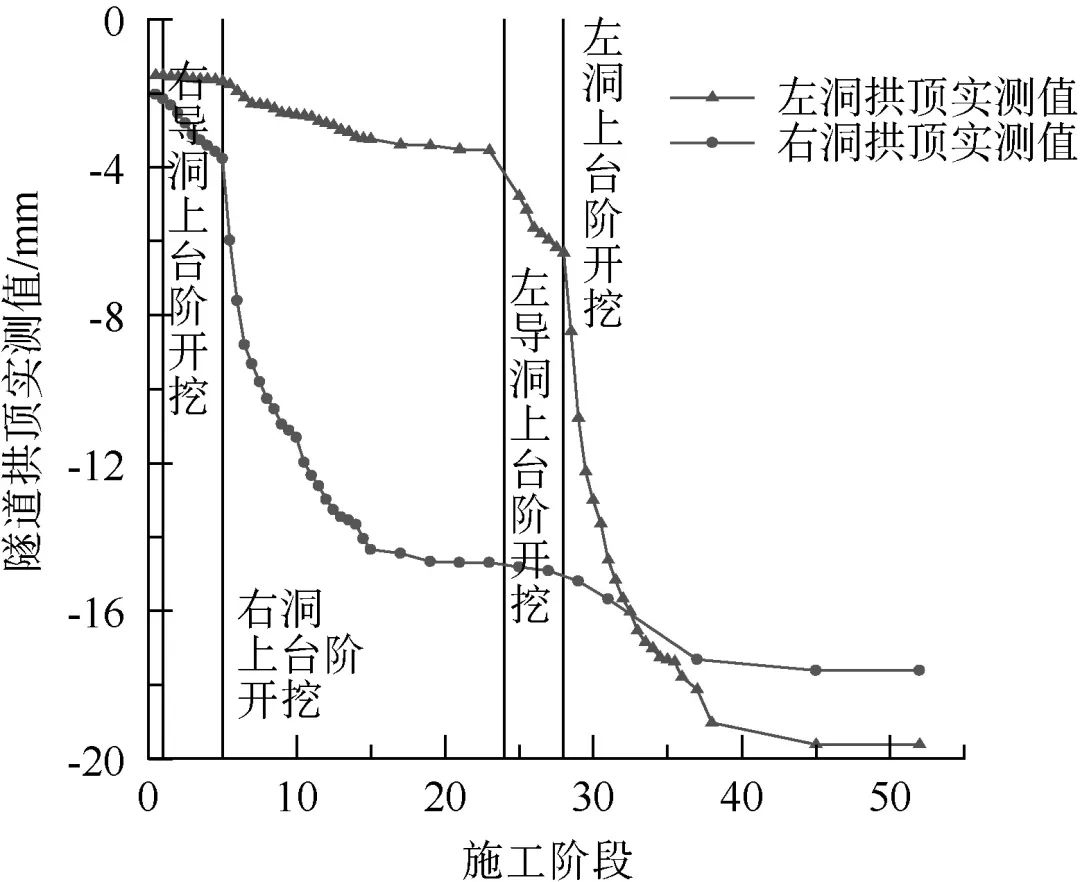

[5] based on the leijiatai multi arch tunnel, compared and analyzed the numerical simulation values with the tunnel construction monitoring data, and obtained the stress characteristics of the multi arch tunnel structure.

Key words: asymmetric multi arch tunnel; Middle partition wall; Engineering monitoring; Numerical simulation; In recent years, the multi arch tunnel structure is often used in highway tunnels and urban tunnels because of its many advantages, such as avoiding the opening division, maintaining the smooth alignment of the route, occupying less land, high utilization rate of underground space, being conducive to environmental protection, adapting to urban development and so on.

The tunnel axis is nearly vertical to the contour line of the terrain, and there is no bias pressure; The surrounding rock of the tunnel body is mainly moderately weathered slate, with developed joints and fissures, broken rock mass, and relatively poor engineering geological conditions.

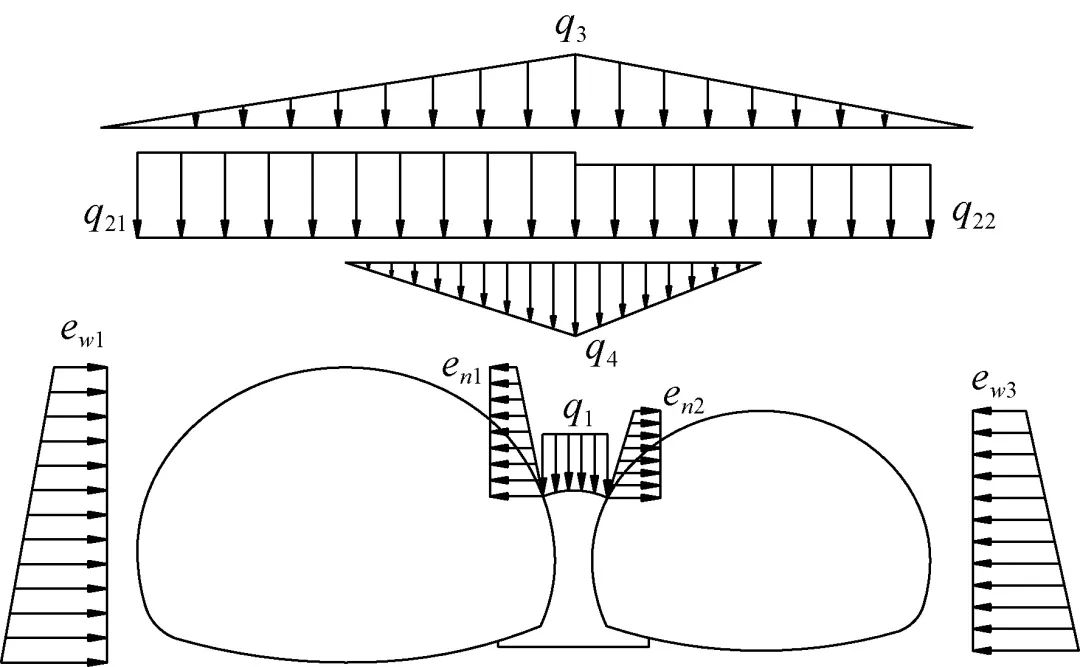

Abstract: in order to study the mechanical properties of the asymmetric middle partition wall in the asymmetric multi arch tunnel during construction, taking the saizijie tunnel in Hunan Province as the engineering background, based on the Platts equilibrium theory, the mechanical characteristics and deflection mechanism of the middle partition wall are analyzed; Midas/gts three-dimensional numerical model is established to simulate and analyze the change rules of displacement and stress of different forms of middle partition wall during construction, and the tunnel construction monitoring data and numerical simulation data are compared and analyzed.

[4] carried out numerical simulation of the construction process of a biased multi arch tunnel, and obtained the variation law of the stress and deformation of the key points on the top of the middle partition wall with the construction steps under different excavation sequences.

[1] compared and analyzed the numerical simulation of the composite middle wall with two shapes, and optimized the thickness of the middle wall.

At present, there is no corresponding design, construction technical specifications and standards to follow.

The deformation and stress of the middle partition wall of asymmetric multi arch tunnel is more complex than that of symmetric multi arch tunnel, which makes it more difficult to determine the reasonable form and size of the middle partition wall.

The compound curved middle wall is adopted, and the tunnel excavation adopts the “middle pilot tunnel – double side pilot tunnel construction method”, in which the main tunnel adopts the construction sequence of small tunnel first and then large tunnel [7], and the specific construction procedures are shown in Table 1..

The thickness of the overlying soil layer is about 6m, and the underlying bedrock is strongly ~ moderately weathered slate.

Therefore, it is of great significance to study the stability of different forms of middle partitions in the construction of asymmetric multi arch tunnels.

Based on the monitoring and measurement data, Yang Guolin et al.

Project background: the plug boundary tunnel is an asymmetric double arch short tunnel, with a design length of 208m, the pile number of the monitoring section is zk2+595, the maximum buried depth of the left tunnel is 56.5m, the net width is 15.8m, and the net height is 12.2m; The maximum buried depth of the right tunnel is 58.5m, the net width is 12.8m, and the net height is 9.8m; The middle partition wall is 2.2m thick.

As the most important stress-bearing structure of the multi arch tunnel, the middle partition wall is the focus of the design and construction of the multi arch tunnel.

1.

Caoyuanyuan et al.

Zhang Niu, Liu Hui, Liu Chang, Deng Xiaozhao, Changsha University of technology, Changsha tuozheng Transportation Technology Co., Ltd.

Li Jianyu and others [6] analyzed the stress mechanism and stability of symmetrical and asymmetric middle partitions based on theoretical analysis, three-dimensional modeling and field measured data of Nanshan Road double arch tunnel.

Zheng Zongxi et al.

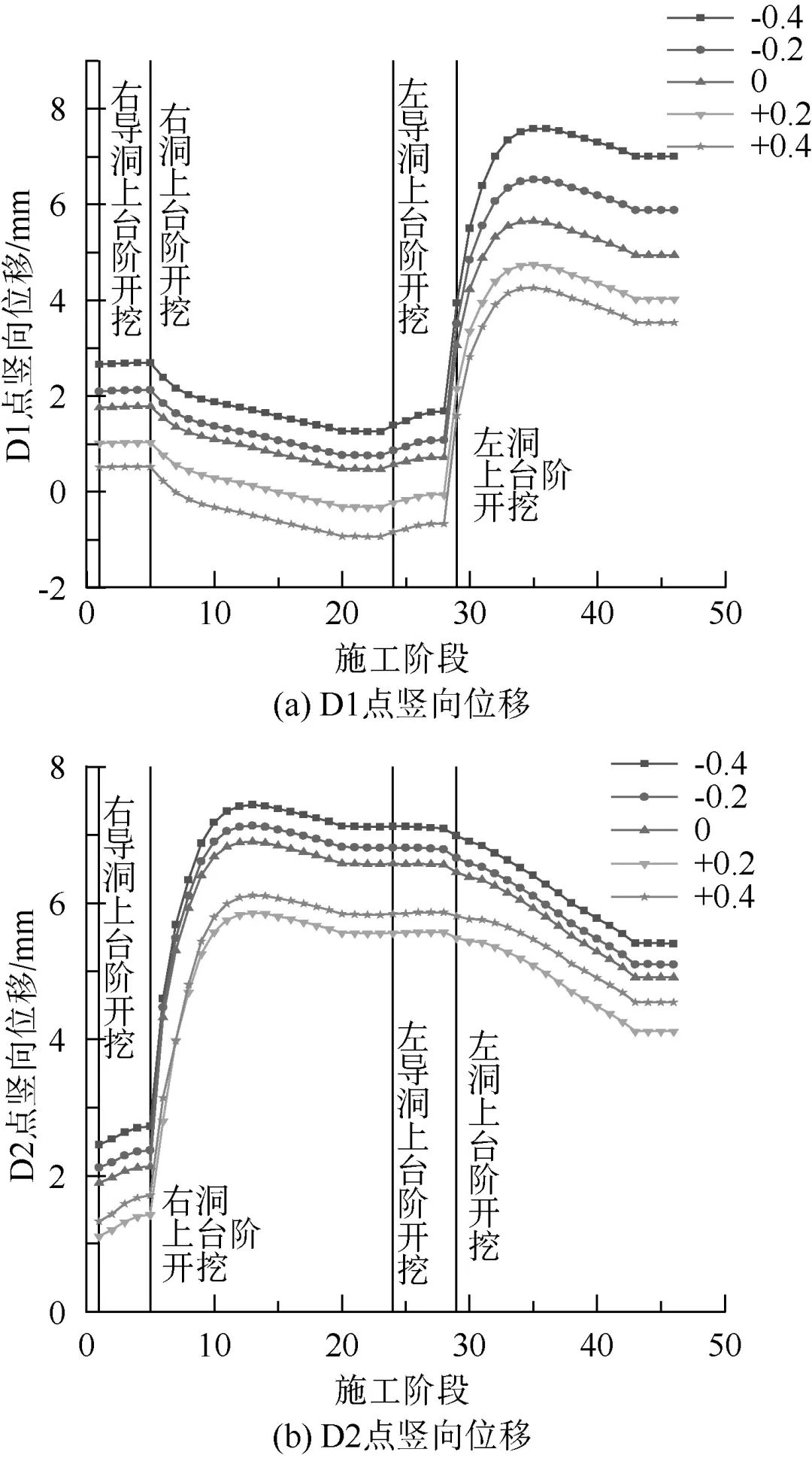

Based on the asymmetric multi arch tunnel in Hunan Province, midas/gts finite element software is used to simulate the actual excavation process of the asymmetric multi arch tunnel, and the force and deformation laws of the two types of middle walls in the asymmetric multi arch tunnel are compared and analyzed, which provides more references for the selection of the structural type of the middle wall in the asymmetric multi arch tunnel under similar conditions.