After the lifting is in place, the scaffold is fixed to the building, Remove the restraint between the scaffold and the lifting mechanism, install it at the position required for the next lifting, and then fix the scaffold on it to achieve the next lifting.

Fall arrest device: the fall arrest device is installed with a return spring.

The on-site personnel shall check whether the safety protection, emergency access, lighting, toxic and harmful gas content and other working environment meet the requirements before operation.

Key points for supervision before construction of attached lifting scaffold key points for supervision of construction risks of attached lifting scaffold climbing installation (1) the height of the scaffold shall not be greater than 5 times the floor height.

Wall bearing: (1) a wall bearing shall be set at each floor covered by the vertical main frame.

When in use, a group of anti tilting devices are set on each wall attached support, with a total of three groups from top to bottom.

When lifting, the binding force between the scaffold and the building is loosened and fixed to the lift structure.

The on-site personnel shall supervise and check whether the operators have passed the three-level safety education.

From | network data introduction to attached scaffold attached lifting scaffold is to set up a certain height and attach it to the engineering structure through the attached support structure.

4.

(3) The support span of the frame arranged in a straight line shall not be greater than 7 meters.

Those who have not passed the safety education and are qualified shall not work.

(4) The horizontal cantilever length of the frame shall not be greater than 2 meters, and shall not be greater than 1/2 of the span.

The length of the screw exposed from the end of the nut shall not be less than 3 buckles, and shall not be less than 10mm.

5.

However, when the lifting frame falls unexpectedly, due to the existence of gravity acceleration, the lowering speed of the frame body accelerates, so that the anti falling device cannot be reset at a uniform speed, resulting in the failure of the guide rail cross brace to pass through the anti falling device and complete the anti falling braking.

The size of the base plate shall be determined by the design, and shall not be less than 100mm × 100mm × 10mm。 (5) The strength of the concrete at the connection of the attached bearing supported on the building shall be determined according to the design requirements, and shall not be less than C10..

7.

2.

Relying on its own lifting equipment and devices, it climbs layer by layer with the construction of the engineering structure to the top of the structure, which can meet the requirements of structural construction, installation construction The construction process and safety protection needs of workers when operating outside the building in the construction stages such as decoration construction.

Those who do not hold certificates or whose certificates do not meet the requirements shall not operate.

(1) The fall prevention device shall be set at the vertical main frame and attached to the building.

3.

6.

There shall be no less than one fall prevention device at each lifting point.

When the frame body drops normally according to the design speed, the return time of the fall arrest device is that the guide rail cross brace of the frame body just passes through.

Electric hoist should be checked and maintained regularly.

The guide wheel on the anti tilt device and the guide rail on the main frame form a guide wheel guide rail device, which makes the frame slip and plays an anti tilt guide role during the lifting process.

(3) Fall arrest devices and lifting equipment must be separately fixed on the building structure.

(3) In the process of lifting, anti tilting and guiding structural devices shall be set on the wall attached support.

The on-site personnel shall check the personal safety protection measures of the operators before operation.

(2) The width of the frame shall not be greater than 1.2m.

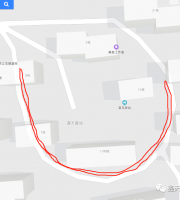

Only one span and two folds are allowed for the broken line layout, and its support span should not be more than 5 meters, and the outer edge of the break point should not be more than 2 meters from the span center.

(5) The product of the full height of the frame and the support span shall not be greater than 110 square meters.

(2) During use, the vertical main frame shall be fixed on the wall bearing.

For the frame arranged in a broken line or curve, the distance outside the frame at the support points of the two adjacent main frames shall not be greater than 5.4 meters.

(4) The support attached to the wall shall be connected with the building by anchor bolts, and the nuts of tension bolts shall not be less than 2, or the spring coil plus single nut shall be used.

Anti roll device: it can prevent the attached lifting scaffold from overturning inside and outside.

When installing the electric hoist, it should be noted that the electric hoist should not collide with the frame, the chain should be smooth without kinking, and the hook is equipped with anti decoupling.

The on-site personnel should always pay attention to the changes of the weather environment and stop their construction in time when they do not meet the construction requirements.

The fall prevention device must play a role in the use and lifting process.

Whether the certificates held by the operators of special types of work meet the requirements.

(2) The fall prevention device must be a mechanical full-automatic device, with dust-proof and pollution prevention measures, and should be sensitive, reliable and operate freely.

Attached lifting scaffold construction safety supervision classification safety site supervision content 1 Before operation, the on-site personnel must be familiar with the safety technical disclosure of the divisional and subdivisional works, whether there is a construction plan and whether the technical measures are in place, and supervise the operators to carry out safe operation according to the technical disclosure.

Adjust the lifting direction of each electric hoist hook to be consistent with the specified direction of the electrical control device, and install a tension sensor to slightly tighten the electric hoist.

When working at heights and standing by, always pay attention to the movement of people around, and avoid cross operation.

Basic principle of attached lifting scaffold: the scaffold and specially designed lifting mechanism are respectively fixed (attached) to the building structure by using the bearing capacity of the poured concrete of the building.

The on-site personnel shall set up safety warning measures during the on-site process, patrol the construction site and the surrounding environment, and timely correct the illegal command, illegal operation and violation of the operation process.

It has anti overturning and anti falling devices.

The lifting of the scaffold is realized by lifting power equipment.