The longitudinal reinforcement of the column shall be reliably positioned, firmly bound and vertically vertical.

The position of the protruding reinforcement of the lower wall and column deviates too much from the design requirements, and it cannot be overlapped with the reinforcement of the upper wall and column.

When the protruding reinforcement of the lower layer is smaller than that of the upper layer, the overlapping position should be in the lower layer.

⑥ The anchoring of horizontal reinforcement at the corner of the wall does not meet the requirements.

The anchoring length and method of horizontal reinforcement at the corner of the wall do not meet the requirements.

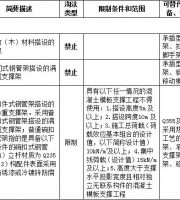

The anti-seismic anchorage length of 18mm grade III reinforcement is not enough, and it should be 42d in C25 concrete.

The horizontal reinforcement of the shear wall is not long enough and does not reach the edge of the end column.

② The anchorage length of the secondary beam reinforcement into the main beam does not meet the requirements.

③ The length of wall and column reinforcement extending into the foundation cushion cap or extending out of the floor and roof is not enough.

Stable supporting measures such as hooping and temporary support can also be taken.

The wall column reinforcement joints shall be staggered for at least 500mm and not less than 35d.

The vertical reinforcement of the wall is evenly distributed, and the binding level and spacing of the horizontal reinforcement are uniform, meeting the requirements.

The anchoring length of the beam reinforcement into the wall is not enough, and the bending end is not up to 15d.

③ The material shall be cut in strict accordance with the design requirements and the requirements of 03g101-1 leveling method to ensure that the anchorage of reinforcement at all places meets the requirements.

② The size, grade, shape, size, quantity, anchorage length, joint position and blanking length of reinforcement meet the design requirements.

The top structure of the vertical reinforcement of the shear wall does not meet the requirements, and the anchoring length and anchoring method do not meet the requirements.

The staggered length of adjacent joints of wall column reinforcement meets the requirements.

The distance between the two rows of bars at the bottom of the beam and the bottom bar is too large.

The spacing of beam reinforcement at the beam column joint does not meet the requirements, and the position of reinforcement does not meet the requirements..

The anchorage length of the beam into the wall meets the requirements, and the bending section also reaches 15d.

③ The negative reinforcement of the beam support is disconnected at the node, and the full-length reinforcement is not used, but is installed by binding and overlapping.

⑤ The size and proportion of the main load-bearing reinforcement are wrong, or the reinforcement is missing.

④ If the anchorage length is not enough, it is necessary to re cut or weld to lengthen, or adjust the position of reinforcement appropriately.

Quality standards for installation of main stressed reinforcement of walls and columns and common quality problems: ① the measures for fixing reinforcement are unreliable, or when pouring concrete, it is bumped and tilted by vibrators or other things, and it is not reset and corrected in time.

The beam reinforcement is anchored into the column and does not cross the column centerline for 5D.

The first horizontal reinforcement is too far from the root.

③ The length of horizontal reinforcement of shear wall is insufficient.

⑦ The concealed acceptance of reinforcement shall be done well before concrete pouring to ensure the installation quality of reinforcement.

The reinforcement of the end column of the shear wall is seriously offset and has not been properly treated.

⑤ The anchorage length of plate bottom reinforcement or surface reinforcement into the beam is not enough to meet the design or specification requirements.

Quality standards for the installation of the main stress bars of the beam and common quality problems: ① the spacing between the bottom of the beam and the surface bars does not meet the minimum clear distance requirements, or the spacing between the bars is different and chaotic, and the spacing between two or more rows of bars does not meet the requirements (falling into the beam or the upper and lower rows are too tight).

② The joint bars of wall columns in the foundation shall be short bars inserted, connected layer by layer, and fixed by spot welding with positioning stirrups that make the joint bar skeleton not deformed.

The anchorage length of the surface reinforcement of the cantilever beam is not enough, and the reinforcement skeleton is inclined.

② The pre inserted reinforcement of the foundation is skewed or out of position.

If it is not long enough, it should be removed and redone in time.

③ The stirrup shall be made as required and bound firmly with the longitudinal reinforcement of the column.

The anchorage length of the ground beam into the cushion cap is not enough.

The method and length of reinforcement anchoring meet the requirements of design and leveling method.

The column reinforcement shall be firmly positioned, accurately positioned and evenly spaced.

The length of shear wall reinforcement extending out of the floor is insufficient.

⑧ The vertical stressed reinforcement of the wall column and the adjacent reinforcement joints are not staggered as required or the staggered distance does not meet the requirements.

⑥ When the column intersects with the beam and wall, the principle that the column reinforcement wraps the beam and wall reinforcement should be followed.

If the reinforcement material is wrong, the column should be all grade III steel of 22, and one of them is the wrong reinforcement of 20.

At the intersection of primary and secondary beams, the secondary beam reinforcement is placed under the main beam reinforcement, and the installation position does not meet the requirements.

⑤ If the length of wall and column reinforcement extending out of the floor is not enough, it should be pre inserted in time before concrete pouring to ensure the length of the upper end.

⑥ When the section size of the wall and column changes, the main reinforcement is improperly bent, which does not meet the requirements.

The reinforcement of the top anti beam is anchored incorrectly and is not anchored into the wall column.

2.

Source: quality standards and common problems of supervision reinforcement anchoring quality common problems: ① the anchoring length of beam reinforcement extending into the wall and column is insufficient or the anchoring method is improper, and the materials with seismic requirements are not cut according to the design requirements.

The anchoring length of the top column reinforcement is insufficient, and the beam reinforcement is not anchored into the node.

④ The anchorage length of the horizontal reinforcement of the shear wall at both ends, corners, cross joints, coupling beams and other parts, as well as the reinforcement around the hole, all meet the seismic design requirements.

⑦ The deviation reinforcement is not handled properly.

The staggering of adjacent joints of wall column reinforcement is only 460mm, which does not meet the requirements of 35d and 500mm.

The vertical bars of the wall are evenly distributed, the horizontal bars are bound horizontally and evenly spaced, and the spacing of tie bars is less than 600, which meets the requirements.

④ The spacing of wall and column reinforcement is uneven, too large or too small, and the binding is not vertical.

The negative reinforcement of the beam support is disconnected at the node and is bound and overlapped, which does not meet the requirements.

④ The anchorage of cantilever beam reinforcement or cantilever plate reinforcement does not meet the design requirements or specification requirements.

The shear wall reinforcement is seriously offset, and the treatment method does not meet the requirements.

Prevention measures: ① make technical disclosure.

The pre inserted reinforcement of the wall is skewed, and one end deviates from the axis.

After the completion of column head concrete construction, the reinforcement is completely reset and meets the requirements.

Prevention and control measures: ① mark the dimension line of the wall and column cross-section frame on each floor according to the design requirements, and then use two stirrups or positioning horizontal bars to spot weld and fix the longitudinal bars extending from the lower layer with each longitudinal bar at the floor elevation of this floor and 500mm above, so as to ensure the position of each longitudinal stress bar.

④ The rebar position of the main and secondary beams is incorrect.

④ The length of the horizontal reinforcement of the shear wall must be cut in strict accordance with the requirements of the drawing.

3.

The vertical reinforcement and horizontal reinforcement of the shear wall are evenly distributed, the position is accurate, and the tie bars are in place and installed reasonably.

The anchor length of the ground beam into the cushion cap is too short to meet the requirements.

② Review the reinforcement blanking sheet of the team.

③ Tie bars or support bars shall be bound between the two rows of reinforcement of the shear wall, and the vertical and horizontal spacing shall not be greater than 600mm.