The rated minimum speed to the maximum speed of the mixing plant shall be adopted respectively, during which a cold bin shall be separately fed for 5-10min at least at 5 points.

Once the opening size is changed, the above curve must be re measured.

Before the construction of test road, the performance of modified asphalt shall be inspected.

The optimum asphalt amount shall be determined by the designed asphalt amount and the three kinds of asphalt amounts of ± 0.3%.

It is required to meet the requirements of the volume characteristics of the mixture specified in the design, and trial mixing and trial paving shall be carried out to verify the production mix proportion.

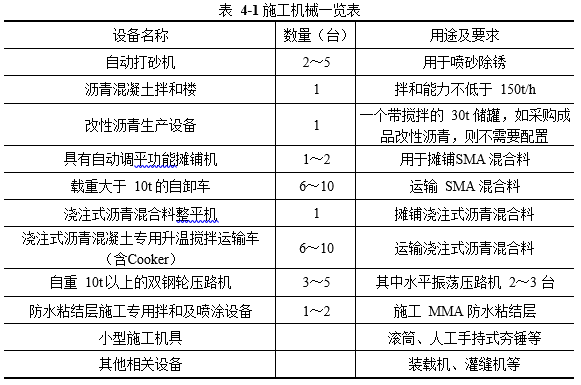

4.2.1 mechanical equipment requirements see table 4-1 for details of construction mechanical equipment, and the specific quantity shall be determined according to the situation of each project.

4.2.5 construction organization design before the construction of test road, the construction organization plan of test road pavement and steel bridge surface pavement shall be formulated..

4.2 preparation before the pavement construction: before the steel bridge surface pavement construction (including the test road pavement construction), the mechanical equipment, test and detection equipment, pavement materials required for the pavement construction shall be prepared according to the contract requirements, and the site proportioning design, test mixing and sampling performance test, raw material performance inspection and detailed construction organization design shall be completed.

When the feeding speed needs to be adjusted, the corresponding feeding speed of each cold bin shall be found from the above-mentioned relationship curve to maintain the feeding balance of the cold bin.

The relationship curve between the rotational speed and the feeding speed shall be drawn for each cold bin.

After the test, the opening size of the cold bin must be completely fixed.

The following methods are for site reference, and other suitable methods can also be used.

4.2.3 metering inspection of mixing plant and measurement of cold material feeding speed (1) metering inspection of weighing system of mixing plant metering inspection of mixing plant mainly refers to the metering inspection of hot material bin, mineral powder bin and asphalt weighing system of mixing plant to confirm the accuracy of weighing of mixing plant.

When a certain feeding speed required by a certain graded mixture is higher or lower than the allowable speed range of the mixing plant, the opening size of the cold bin shall be readjusted and the above measurement shall be completed again, so that the corresponding speed of all required feeding speeds is within the allowable range of the mechanical equipment.

All other vehicles (including trolleys), personnel and machinery unrelated to the construction are strictly prohibited from entering the pavement construction scope.

If the project provides a test Road site, the summary and commencement application report shall be submitted after the completion of the construction and inspection of the test road, which shall be signed and approved by the supervision engineer, The construction can be started only after the commencement order is issued.

(2) The feeding speed of the cold bin shall be determined by a suitable and easy to operate method on site to determine the relationship between the feeding speed and the actual feeding speed under the condition of a fixed opening size, so as to ensure the feeding balance of the cold bin during the mixing process.

The processes to be accepted include: (1) sand blasting and rust removal; (2) Waterproof adhesive layer; (3) Lower pavement layer (protective layer); (4) Pavement surface course.

The accuracy of the weighing system of the mixing plant shall be tested by appropriate methods that are easy to operate on site.

After the design of the target mix proportion of the on-site mixture is completed, the SMA mixture must be subject to leakage test (the test temperature is the actual mixing temperature) to check the stability of the mixture during storage and transportation.

During each construction, it is necessary to test the softening point, penetration, ductility and other key performance indicators of the provided modified asphalt samples in batches to master the properties of the modified asphalt in time.

According to the needs of the project, the experienced operators of the mixing plant shall initially determine the opening size of the discharge opening of the cold bin of the mixing plant and fix the opening size.

Focusing on the road (bridge) methacrylic acid resin (MMA) specialty, specialty, and then specialty steel deck pavement construction requirements 4.1 basic provisions for pavement construction before the commencement of pavement construction, the construction unit shall submit the quality inspection report of the raw material supplier and the project inspection report.

After the completion of each pavement construction process, the next process can be carried out only after the acceptance of the supervision engineer.

All mechanical equipment shall be kept in good working condition, and all measuring equipment shall be checked.

After the design of the target mix proportion of the pouring asphalt mixture and SMA mixture is completed, the production mix proportion design shall be carried out to determine the proportion of each hot bin and mineral powder.

4.2.2 raw material performance inspection each raw material requires the material supplier to provide a quality inspection report.

The design results of the target proportion of the mixture shall meet the requirements of the above technical indicators.

The metering accuracy of the mineral powder metering bin and asphalt metering tank in the mixing plant shall be tested, and the error shall be less than 1.0%.

The test methods and results shall be approved by the supervisor.

After the pavement is completed, the construction unit of other works (such as anti-collision railings, traffic signs, etc.) shall pay full attention to protecting the steel bridge surface pavement.

The material truck shall enter the pavement construction scope according to the specified operation and driving method.

The modified asphalt can be used only after it is confirmed that the modified asphalt meets the performance requirements of the modified asphalt in the implementation requirements.

The management and technical personnel shall be present.

4.2.4 mix proportion design of on-site mixture before the pavement construction of test road, the target mix proportion design and performance test of SMA mixture and pouring asphalt mixture shall be conducted.

When mixing the mixture, it can be calculated according to the estimated mixing capacity of the mixing plant and the target proportion of the mixture, and the required corresponding rotation speed can be found from the relationship curve between the above rotation speed and the feeding speed, and the material can be fed according to this speed to ensure the balance of the feeding speed of the cold bin.

Before the completion of steel bridge surface pavement, construction vehicles are not allowed to turn, turn around and emergency brake on each pavement layer, and the driving speed shall not be higher than 10km / h.

The metering system of the mixing plant shall be used to measure the stones fed, so as to determine the relationship curve between the speed and the feeding speed of the bin under the condition of the opening size.

The following materials shall be inspected by the supervisor in the field laboratory or sent to the project quality inspection center to complete the quality inspection and issue the inspection report: (1) aggregate; (2) Mineral powder; (3) Asphalt.

From the beginning of construction (sand blasting and rust removal) to the completion of pavement surface construction, traffic shall be closed and other works other than pavement construction are not allowed to cross.