④ Mark the cross centerline of the pad stone before erecting the beam; Check the longitudinal and transverse misalignment of piers and abutments, and the transverse distance between the centers of bearings at the same end.

(8) When the mortar strength does not reach 20MPa, it is strictly prohibited to remove the temporary upper and lower connecting rods of the bearing and the bridge erecting machine to pass the hole..

2.1.3 Formulate construction safety assurance measures and propose emergency plans.

The grouting shall be carried out from the center of the bearing to the surrounding with a special funnel, hard hose and flexible hose until the grouting materials are fully filled, and appropriate curing measures shall be taken according to the site conditions.

When the mortar strength reaches 20MPa, remove the upper and lower connecting rods of the support.

After the technician determines the position and installation direction of the support, use a 3-ton forklift to manually install the support at the bottom of the box girder.

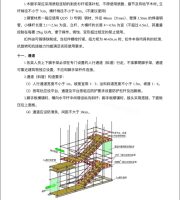

(2) Guidance for bearing grouting: formwork installation → mortar mixing → mortar grouting → mortar curing → removal of temporary supports → removal of bearing fasteners.

⑥ The gravity grouting method is adopted for grouting.

The estimated slurry volume is sufficient, and the grout is filled at one time.

The reaction force of each jack does not exceed 5% of the average value.

(7) The bearing and the beam bottom, and the bearing and the supporting pad stone shall be closely attached without gaps.

⑤ Stop when the bearing is 400mm away from the top of the pad stone when falling the beam, and the front and rear pier operators shall install and tighten the bottom plate bolts of the lower bearing; Technicians use plumb bob for preliminary alignment; When it is 50mm away from the top of the pad stone, conduct longitudinal and transverse fine adjustment to make the center line of the bearing coincide with the center line of the pad stone.

(5) All components on the support must be aligned vertically and horizontally.

Operation preparation 2.1 Office technical preparation 2.1.1 Organize personnel to get familiar with design drawings, specifications and technical standards, and conduct joint review of drawings.

Operation instruction for bearing installation 1.

③ Before the installation of the support, mark the center line on the support.

The grouting hole is not lower than the bottom of the beam.

Support installation construction process and construction methods and requirements 3.1 The support installation process is as follows: ① Before the support installation, carefully check whether the support connection is normal, and do not loosen the upper and lower support connecting bolts at will; Check the relative height difference of the four corners of the base plate of the bearing and the longitudinal and transverse misalignment of the movable bearing.

(4) After the support is installed at the bottom of the box girder, the connecting bolts between the support and the girder shall be tightened.

The actual grouting volume should not have too much error with the calculated value, and the lack of grout in the middle should be prevented.

Check whether there is mortar leakage, replenish the mortar at the leakage place if necessary, tighten the anchor bolts of the bearing plate, and remove the temporary connecting angle steel and bolts of the upper and lower plates of the bearing.

⑥ After the box girder is correctly aligned, the support anchor bolt shall be anchored in the anchor bolt hole of the pad stone with mortar.

Scope of application: bearing installation for prefabricated box girder and beam fabrication at bridge site.

2.2 Field technical preparation 2.2.1 Establish a sound overhaul and maintenance system, and conduct flaw detection on important parts of equipment regularly.

2.

④ Special mortar mixer shall be used for mixing, and mixing shall be carried out in strict accordance with the construction mix proportion, material consumption and time to ensure that all construction can be completed before the mortar loses its fluidity.

The pier operators shall be arranged to roughen the top surface of the pad stone, and the soil, floating sand, water, ice, snow, oil and other debris on the anchor bolt hole and pad stone surface shall be cleaned.

(3) The bearing shall be stored away from direct sunlight, rain and snow, and kept clean; It is strictly forbidden to contact with objects that affect the bearing, such as acid, alkali, oil, organic solvent, etc., and it is more than 1m away from the heat source.

⑤ Before grouting of the bearing, the surface of the bearing pad stone shall be wetted with water.

① Roughen the surface of the bearing pad stone at the position of the bearing, and clean the sundries in the anchor bolt hole; 5 cm formwork × The 5cm equilateral angle steel is made, and it is closely connected with the top surface of the pad stone with engineering double-sided adhesive tape, and is sealed externally with clay to prevent slurry leakage during gravity grouting.

② Clean the embedded steel plate at the beam bottom, and apply grease to the bolt hole connecting with the upper support.

2.1.2 Prepare technical disclosure data and operating procedures for bridge bearing installation, and carefully organize technical disclosure.

When the installation temperature is different from the design temperature, the staggered distance of each component of the longitudinal support must be determined by calculation.

If there is a gap, it shall be filled by grouting.

There shall be no gap between the bearing and the embedded steel plate at the beam bottom.

③ The box girder falls on the temporary support jack, and the position and elevation of the beam body are adjusted by the jack.

2.2.2 Collection of various external technical data involved in the construction operation layer, such as bearing size.

(2) The quality of the support and accessories shall meet the design requirements, the support connection shall be normal, and the connecting bolts of the upper and lower plates shall not be loosened at will.

② The anchoring mortar shall be the special bearing grouting mortar (CGM-9 high-strength non shrinkage grouting material).

After the materials arrive at the site, they shall be accepted and tested in a timely manner, and shall be marked for use after being qualified.

The gap between the lower part of the bearing and the anchor bolt hole is filled.

⑦ When the mortar strength is greater than 20MPa (about 2 hours), remove 320t oil cap.

There shall be no gap between the upper support plate and the embedded steel plate at the bottom of the beam.

2.2.3 Understand the traffic, power lines, communication lines along the line and the obstacles that affect walking.

(6) The nuts of the upper and lower bolts of the support shall be installed completely and coated with grease without looseness.

3.

3.2 Construction methods and requirements ⑴ After the bearing arrives at the site, the product certificate, the list of accessories and the relevant material report or inspection report must be checked, and the bearing appearance must be comprehensively checked.

Screw the connecting bolts between the support and the beam body with a force amplifier.