The ambient temperature is greater than 12 ° C and the humidity is not greater than the guaranteed quality.

First, it is good.

The fabric is a resin rich layer, which is a key part of corrosion resistance, and must be full, pinhole free and bright (3) Quality and technical standards of raw materials: epoxy resin E44, curing agent T31, aluminum tripolyphosphate APW-1, active diluent 690, silane coupling agent II, construction scheme 1, cement mortar base course grinding: to ensure the quality of the protective layer and ensure the binding force between the protective layer and the substrate, after polishing with an electric wire brush, clean it with a soft brush or compressed air 2 Spraying epoxy resin adhesive for the bottom layer: after the cement mortar base course is treated, the adhesive for the bottom layer shall be sprayed as early as possible to avoid secondary contamination; The spraying interval of the bottom layer rubber shall be more than 8 hours.

The specification and number of layers of glass cloth shall comply with the design requirements.

The spraying shall be uniform and no defects such as sagging shall be missed.

The prepared surface rubber must also be used up in 60 minutes Quality acceptance and verification guarantee items: basic items of inspection items that have a decisive impact on the project quality: items with allowable deviations that have an important impact on the project quality: inspection items that can meet the project safety and use functions 1.

The prepared lining rubber must be used up in 60 minutes.

Before the lining cloth, first brush and spray a layer of epoxy resin adhesive, pave the glass cloth without bubbles and hollows, and then brush and spray a layer of epoxy resin adhesive to complete the three cloth lining.

3.

The construction site shall be kept clean, and the remaining flammable, explosive and other debris shall be cleaned after the operation is completed.

The curing time of glass fiber reinforced plastic ground shall be ≥ 10 days, the storage tank shall be ≥ 20 days, and the service time of room temperature solidification shall be 30 days..

(3) Allowable deviation items: the surface flatness and slope tolerance of ground FRP are the same as the requirements of the base course.

The construction site shall be well ventilated, equipped with fire-fighting equipment and no smoking and fire warning signs to ensure safety.

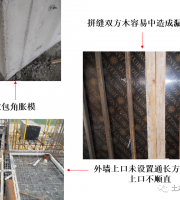

Treatment of cement mortar or concrete base course (1) guarantee items: strength test report of cement mortar or concrete base course, It should meet the requirements of the design and construction specifications (2) Basic items: cement mortar and cushion should be firmly combined without obvious cracks, sanding and shelling, and the internal and external corners should meet the requirements of the Construction Specifications.

The concrete base course shall be dense and flat without obvious honeycombs and pitted surfaces.

Resin rich layer rubber: after 12 hours of natural curing of the lining, evenly spray the surface layer epoxy resin rubber, and then spray the second layer rubber after the first layer is hardened.

In addition, the resin rubber of FRP is full, and the thickness is not less than the design thickness.

Click the blue words above to pay attention to I.

The mix proportion of the layer, lining cloth, and surface rubber shall meet the requirements.

Safety protection and precautions Strictly control the technical conditions of the construction environment.

The base material shall be applied with two layers of epoxy resin thin oil, so that the rubber can penetrate into the cement mortar to drive away the air of the cement mortar, improve the strength, and ensure the connection with the base course.

(3) Allowable deviation items: the surface evenness of the base course shall be checked with a 2m ruler, the allowable deviation shall not be greater than 5mm, and the maximum deviation may be 6mm; The allowable deviation of the slope is ± 0.2% of the slope length, and the maximum deviation value shall not be greater than 302.

The prepared epoxy resin rubber shall be used up in 40 minutes, Reach the number and thickness of layers.

4.

4.

5.

4.

Construction standard (1) GB50212-91 Code for Construction and Acceptance of Anticorrosion Engineering of Buildings (2) GB50224-95 Standard for Quality Inspection and Assessment of Anticorrosion Engineering of Buildings (1) Base course treatment requirements: according to GB8923 and GB50212, cement mortar or concrete base course must be firm, dense and flat, and the slope and strength shall meet the design requirements without sand, shell, cracks, honeycombs, pits and other phenomena; When flatness is checked with a 2m ruler, the allowable gap is not more than 5mm; The moisture content is no more than 6% when the thickness is 20mm, and the wet curing formula used in this scheme is not subject to this restriction; Before construction, the floating ash, cement and loose parts on the surface shall be cleaned; The surface polluted by grease and chemicals must be pretreated (2) FRP anticorrosive coating: referring to HGJ229 and GB50212, the anticorrosive coating is designed as the process of base oil, three cloth six oil and two surface oil.

The curing during and after the construction shall meet the requirements of the Construction Specifications Delamination is qualified first; And the rubber material is full, the surface is smooth, and the color is uniform.

Glass fiber reinforced plastic lining (1) Guarantee items: the materials shall meet the quality requirements of the Construction Specifications.