The upper part is chiseled by air compressor, and the lower part is left with 10cm for manual chiseling.

The open weld shall be repaired and polished and cleaned with diesel oil; (After each formwork removal, the formwork shall be cleaned and cleaned with diesel oil.

The stacking of finished products shall be marked with the used position, length and specification.

After the installation, check whether the release agent meets the requirements, and brush the nonconforming parts.

Immersion vibrator shall be used for tamping concrete.

During concrete pouring, special personnel shall be assigned to strengthen inspection and adjustment to ensure that the shape, size and mutual position of concrete buildings are correct.

The conditions of concrete curing water are the same as that of mixing water.

There shall be no missing or loose binding of reinforcement buckle, and the cushion surface shall be cleaned.

The sundries in the formwork shall be removed.

In order to prevent the seepage of the foundation pit from collecting, the artificial blind ditch shall be built within the foundation range of the foundation pit to form a drainage network so that the seepage of the base can be completely discharged, and the sump shall be built, equipped with enough submersible pumps to pump water, and the inspection shall be reported in time to avoid exposure and immersion for a long time.

The pouring concrete shall be poured layer by layer from one end along the long side on both sides of the cushion cap to the other end, with a layer thickness of 40cm.

The tamping rod shall be inserted quickly and pulled out slowly, and no undertamping or missing tamping is allowed.

The concrete poured to the top surface must be plastered and polished.

The watering curing time of concrete is generally 7 days, which can be extended or shortened according to the air humidity, temperature, cement type and admixture used.

Ensure that the concrete surface of the pile top is roughened and free of loose debris, and the reinforcement of the cushion cap can be bound only after it is cleaned; Ensure the pile top elevation and the length of the pile reinforcement extending into the cushion cap.

The steel formwork used shall be repaired every time.

If water seepage is found during the excavation of the foundation pit, drainage ditches and intercepting ditches shall be arranged at appropriate positions around the foundation pit to prevent surface water from damaging the excavated foundation pit.

The reinforcement shall be compacted and braced with the pit wall around the foundation pit through steel pipes, jacking, square timber to ensure that the formwork is stable and firm, and the size is accurate.

It is strictly forbidden to break the pile head with excavator or forklift to avoid damaging the main reinforcement.

The bottom reinforcement cushion blocks shall be mortar cushion blocks of the same grade as the cushion cap concrete, arranged in quincunx form, with a spacing of 1.5m.

To prevent slurry leakage and root rot, sponge strips shall be pasted at the bottom of the formwork before the formwork is in place.

The excavation shall be carried out manually with the excavator, and the plane size and elevation of the foundation pit shall be measured and controlled at any time.

④ Quality control of reinforcement processing and binding: during reinforcement blanking, the quality shall be strictly controlled.

⑤ Formwork installation quality control: Before installation, the formwork shall be coated with release agent.

When the temperature is lower than 5 ℃, it shall be covered with thermal insulation, and water shall not be sprayed on the concrete surface.

The number of side cushion blocks shall not be less than 4 per square meter.

For each vibrating part, the vibration shall be carried out until the concrete at that part is dense, that is, the concrete will no longer emit bubbles, and the surface will appear flat and ooze (20~30s is appropriate).

⑦ Concrete curing quality control: after the concrete pouring is completed, it shall be covered and watered for curing as soon as possible after the initial setting, and the concrete surface shall not be damaged or polluted during the covering.

During chiseling, ensure that the concrete of the pile shaft below the design pile top is not disturbed.

When the pile head is broken, air compressor and manual chiseling are used.

② Quality control for chiseling off pile head: before breaking the pile head, mark the elevation line with red paint on the side of the pile body to prevent the pile head from being chiseled too much, which will cause the pile top not to extend into the cushion cap sufficiently.

Attention shall be paid to the binding method of reinforcement skeleton.

The upper layer of concrete shall be poured before the initial setting of the lower layer of concrete.

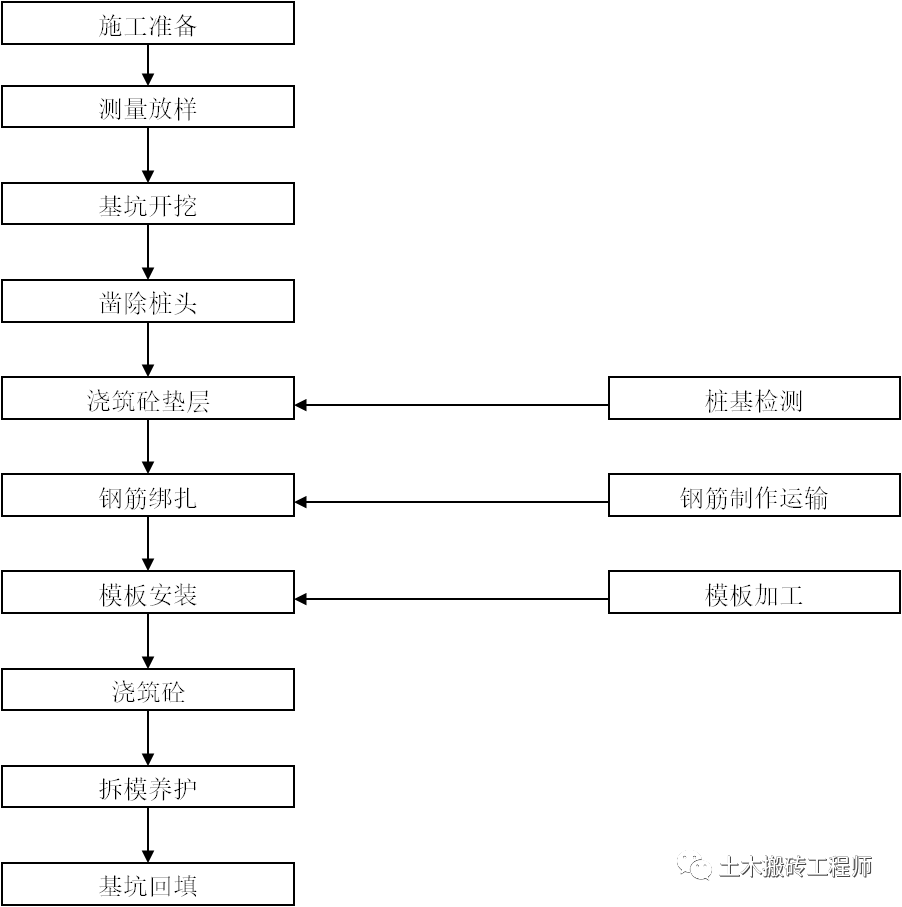

Process flow chart 2.

Snap the peripheral contour line of the reinforcement on the cushion surface, and mark the plane position of each reinforcement with paint.

3.

The allowable deviation of the pile top elevation from the design elevation is 1cm, and the allowable deviation of the length of the pile reinforcement penetrating into the cushion cap is 5cm.

The tamping spacing shall not exceed 40cm, and the vibrator shall be 5~10cm away from the formwork.

③ Quality control of pile foundation inspection and pouring of concrete cushion: first chisel the pile head to the design elevation, cut the acoustic pipe 10 cm above the top of the pile to the same level, and fill the pipe with clean water; In order to ensure the smooth detection, the measuring rope shall be used first φ 28 ㎜ rebar head shall detect all acoustic pipes once, and verify whether the pile length conforms to the design; After the pile foundation is inspected as qualified, the elevation of the cushion surface shall be marked with the reinforcement head before the cushion concrete is poured to ensure that the elevation and flatness of the concrete surface meet the design requirements.

Moreover, the on-site technical management personnel and quality inspection personnel shall irregularly spot check the reinforcement processing in the reinforcement yard, compare the blanking length with the design length, and re fabricate if the error is greater than the design and specification requirements.

It is strictly forbidden to collide with reinforcement and model during vibration.

The unused formwork shall be brushed with diesel oil for rust prevention and sealed with film.) ⑥ Quality control of concrete pouring: the concrete of cushion cap shall be poured into the formwork by chute, and the cushion cap that cannot be set with chute shall be poured into the formwork by pumping concrete.

Ensure that the spacing, quantity and thickness of the reserved reinforcement of the pier column are correct.

The concrete strength of the cushion cap meets the design requirements, the concrete surface is flat and smooth, without honeycomb, pitted surface and exposed reinforcement, and the thickness of the reinforcement protective layer is not less than the design requirements.

Cushion cap construction 1.

When the concrete surface is covered with formwork, the formwork shall be kept wet frequently during curing.

After the installation of the cushion cap formwork, the size, axis and elevation shall be checked.

Before each use, the formwork shall be carefully repaired and leveled.

The formwork shall be straightened by the hanging line method, and its perpendicularity shall be controlled by the hanging plumb ball method.

When the reinforcement is being cut, the reinforcement worker shall cut in strict accordance with the requirements of the design specification, and the overlapping length of the reinforcement shall meet the requirements of the specification.

Key points and requirements for process quality control ① Quality control of foundation pit excavation: the foundation pit shall be excavated only after the pile concrete reaches a certain strength.

When the concrete pouring is close to the top surface elevation of the cushion cap, the line must be hung for leveling, the top surface elevation of the concrete must be strictly controlled, and the laitance generated by vibration shall be removed until the coarse and fine aggregates of the top surface concrete of the cushion cap are uniform.

When tamping in layers, the tamping rod shall be inserted into the lower concrete 5~10cm deep.

The times of watering every day shall be such that the concrete surface can always be kept wet..

Reinforcement binding shall be carried out after the cushion concrete reaches 75% of the design strength.

Cross buckle binding method shall be adopted instead of straight buckle to prevent deformation of reinforcement.