2.3.2 Prestressed tensioning equipment shall be configured according to the controlled tensioning force and stroke.

The stroke length required by the tensioning equipment such as jacks shall meet the elongation requirements of the short strand prestressed tendons during tensioning, and the tensioning of the long strand prestressed tendons should be tensioned and anchored step by step.

1.0.2 This specification is applicable to the machinery configuration in the construction of new railway bridges in general environment.

4 The mixing plant shall be protected from rain, snow and storm, and shall be closed for operation.

1.0.10 During the construction of railway bridges, when the construction organization design changes, the mechanical configuration shall be adjusted accordingly.

The production capacity shall ensure that the concrete can be poured within the required time.

1.

Sewage, waste oil, garbage and other treatment facilities caused by mechanical construction shall be planned, constructed and put into use simultaneously with the facilities in the construction site.

The grinding wheel cutter and thread rolling machine shall be used for the processing of rolling straight threads, the grinding wheel cutter and upsetting straight thread threading machine shall be used for the processing of rutting straight threads, and the press clamp and elevator shall be used for sleeve extrusion.

2.

2.1.4 Electric steel bar bender shall be used for steel bar bending, and special hoop bender shall be used for stirrup bending.

The construction of new railway bridges in plateau, alpine and other special regions shall be configured according to the engineering and environmental characteristics.

3 The measuring system shall be an automatic electronic measuring system, and the measuring accuracy shall meet the requirements of Railway Concrete TB/T3275.

Pump truck or trailer pump can be used for concrete pouring.

1.0.9 The bridge construction shall actively promote the application of “four new” technologies to improve the technical level of bridge construction, and Guoshi shall actively eliminate backward mechanical equipment with low efficiency and high energy consumption.

Its configuration shall be based on the maximum demand for concrete per unit time, according to the following requirements: 1.

The mechanical capacity of tensioning shall be determined by the required tensioning force of the prestressed tendons, which can be calculated according to the following formula: 2.

5 The mixing plant shall be equipped with necessary thermal insulation measures, and ice maker shall be equipped for cooling water in high temperature areas.

1.0.4 The configuration of bridge construction machinery shall be matched with the construction method, adapt to the construction period, meet the construction quality and safety requirements, pay attention to the maximum overall efficiency of machinery, the production capacity of construction machinery configuration shall be greater than the balanced construction capacity, and the balanced construction capacity shall be greater than the construction progress index requirements.

generated by machinery on the surrounding environment.

1.0.7 For bridge construction, the construction machinery operators shall receive vocational training and health education, and work with certificates.

When the flatness of the concrete top surface is required, the mortar lifting vibration leveling equipment shall be used.

1.0.6 The bridge construction shall attach great importance to the protection of the site environment, and take effective measures to reduce the pollution and impact of waste gas, noise, sewage, waste oil, dust, vibration, etc.

The shockproof precision pressure gauge should be selected as the pressure gauge, and the maximum count should be 1.5~2 times of the theoretical pressure gauge reading.

2 General machinery 2.1 Reinforcement processing machinery 2.1.1 Reinforcement processing machinery includes reinforcement straightening, cutting, bending and welding machinery, which shall be configured according to the engineering conditions.

1.0.5 The bridge construction machinery shall meet the quality standards specified by the state.

1.0.8 Mechanical management shall be strengthened for bridge construction, and acceptance, inspection, maintenance and repair of mechanical equipment shall be done well to ensure good mechanical performance and prevent mechanical accidents.

2.1.2 Straightening machine shall be selected for reinforcement straightening.

2.2.2 The concrete for bridge construction shall be configured according to the factory production mode of automatic measurement and centralized mixing.

2.1.6 Three methods of rolling straight thread, upsetting straight thread and sleeve extrusion can be used for rebar mechanical connection.

The delivery capacity of concrete pump and transport vehicle shall adapt to the production capacity, demand and pouring speed of concrete.

Technical Specification for Construction Machinery Allocation of Railway Bridge Engineering Q/CR9225-20151 General Rule 1.0.1 This specification is formulated to improve the level of railway bridge construction mechanization, guide the economic and reasonable allocation of railway bridge construction machinery, meet the construction technical requirements, and ensure the construction quality and safety.

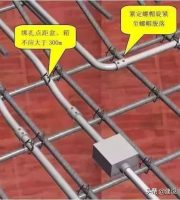

The theoretical pressure gauge reading can be calculated according to the following formula: 2.3.3 When the metal corrugated pipe hole is used, the corrugated pipe rolling machine should be equipped..

2.2.3 Concrete mixer truck shall be used to transport concrete in long distance; concrete pump shall be used to transport concrete in short distance.

When trailer pump is used, it shall be used together with the spreader.

1.0.3 The configuration of bridge construction machinery shall be included in the construction organization design as an important part.

Compulsory mixer shall be used for mixing equipment, and standby mixer shall be equipped.

2.3 Prestressed construction machinery 2.3.1 Prestressed construction machinery includes tensioning equipment, hole forming equipment and grouting equipment, which shall be reasonably selected according to the bridge structure form, production process, prestressed reinforcement specification, type and tensioning force.

2.2.4 Concrete vibrating machinery includes immersion vibrator, attached vibrator, etc.

2.1.3 Mechanical steel bar cutter or hydraulic steel bar cutter shall be used for steel bar cutting.

Concrete production machinery includes mixing equipment, automatic metering equipment, feeding equipment, water supply equipment, power supply equipment, etc.

2.2 Concrete construction machinery 2.2.1 Concrete construction machinery consists of production machinery, transportation machinery, pouring machinery, vibrating machinery, leveling machinery, curing equipment, aggregate cleaning machinery, etc.

1.0.11 In addition to this specification, the configuration of bridge construction machinery shall also comply with the provisions of the current relevant national, industrial and railway standards.

2.1.5 Flash butt welding machine and arc welding machine can be used for rebar welding, and flash butt welding machine is preferred.

The production, use, inspection, detection and supervision and inspection of special machinery and equipment must comply with the relevant requirements of the National Regulations on Safety Supervision of Special Equipment.

2.2.5 Concrete steam curing machinery includes steam boiler, steam curing shed, temperature and humidity control system, etc.

The stretching elongation value of prestressed tendons can be calculated according to the following formula: 3.