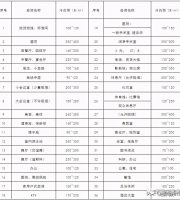

The maximum value of low-speed air duct (m/s) is the field, so the noise control is based on the friction resistance to control the main air duct, supply air, main air duct, return air, main air duct, supply air, branch air duct, return air, branch air duct, residence 35433 apartment, hotel room 57.56.565 office, library 6107.586.1 medium and large venue 46.55.4 bank, and high-end restaurant 7.5107.58.6 department store 9107.586 standard friction loss per unit length (equal pressure method) has always been in the low-speed air duct.

Conversion of various pressure units: standard atmospheric pressure=760mmHg=10.33mH2O=1Kg/cm2=0.1MPa; Introduction to basic parameters of static pressure, dynamic pressure and total pressure External static pressure (discharge part+suction part) The pressure loss calculated here is called external static pressure.

The supply air duct is based on 0.8 – 1.5Pa/m (average 1.00Pa/m), and the return air duct is based on 0.6 – 1.0Pa/m (average 0.82Pa/m).

Millimeter mercury (mmHg): mainly used to indicate the atmospheric pressure.

At this point, it would be wrong to think that no matter the circular or square section area is the same.

But in turn, it is not economical to increase the power of the motor.

The pressure loss of the air duct is increased; 4.

When it becomes a flat rectangular duct, the difference becomes larger.

If the wind speed is high, fine air ducts can be used to save project costs.

In addition to dealing with noise, there are also reasons for reducing the wind speed of the return air duct.

The heat loss on the surface of the air duct is increased; 3.

The total pressure method is designed according to the established principle of P t=P s+P v and the total pressure benchmark.

Purpose: Pneumatic conveying powder.

This relationship becomes larger with the ratio of long side to short side of square duct, that is, aspect ratio.

As the return air duct is located in the air intake part, opposite to the air duct, it is subject to external pressure, so its load should be reduced.

However, the side length of the corresponding round air duct is 3.54m, 13% less than that of the square air duct.

For example, a square air duct with a sectional area of 1m2 has a side length of 4m.

Equal pressure method (equal friction method, constant pressure method) takes the loss per meter of air duct as the method of planting.

Duct design method and step constant velocity method is a method to pre determine the velocity (wind speed) of each part in the duct and determine the sectional area size of the duct.

The bias flow caused in the air duct will also cause the fluctuation of the air volume.

The only method is to reduce the aspect ratio..

When the loss reaching the benchmark is determined, the air supply volume of each part will be planted based on the loss, and the repeated operation of determining the wind speed will be automatically formed.

The production cost of the air duct is increased; 2.

Classification of air duct system composition Air duct name and pressure range According to air duct name of pressure classification Pressure range Velocity range [m/s] Common pressure [Pa] {mmAq} Limiting pressure [Pa] {mmAq} Low pressure air duct under+490 {+50} – below 490 {- 50}+980 {+100} – below 735 {- 75} – below 15 High pressure 1 Air duct over+490 {+50}+980 {+100} – below 980 {- 100} – below 1470 {+150} – below 1470 {- 150} – below 20 High pressure 2 Air duct over+980 {+100} +Below 2450 {+250} and beyond – 980 {- 100} – 1960 {- 200} and below+2940 {+300} and below – 2450 {- 250} and below 20 design related units, the common pressure unit is Pascal (Pa): the international standard pressure unit, which represents the Newtonian force per square meter.

This method has become the mainstream of air duct design.

The so-called internal resistance refers to the loss part inside the air conditioner (coil, filter screen, shell).

If the air volume (m3/h) and standard friction loss (Pa/m) have been determined for the conversion of round air duct to square air duct, the friction loss, wind speed and round air duct diameter can be read out at one stroke from the “air duct resistance line diagram” in the book.

As soon as the diameter of circular duct is read, the dimension can be changed from round to square.

The air velocity in the air duct is specially noted to deal with noise.

Although the speed has been determined, this method is not practical due to different friction losses of each part, as well as many air ducts in branch parts and other factors.

The larger the aspect ratio is, the larger the perimeter of the air duct will be, which will cause the following problems: 1.

The loss of straight pipe section can be obtained immediately after calculating the reference loss when the duct is extended to the maximum length.

This is the most reasonable method in the existing air duct design and has become the mainstream of air duct design.

The static pressure reacquiring method is used for the rare high-speed air duct.

Air duct system design steps Air duct design 1.

Millimeter water column (mmH2O): mainly used to indicate the pressure of air flow, and the main unit used in air duct design; Also used to indicate air resistance.

This is because the outside perimeter of the duct is different.

Kg/cm2 (Kg/cm2): mainly used to indicate the pressure inside the air conditioning system.