3.3.6 The wiring workers with good wiring technology shall be selected to be responsible for the wiring construction of the project.

Cable wiring 3.3.1 After the cable is laid, make cable heads at both ends, wrap them with plastic tape, and then use heat shrinkable tubes to heat shrink.

2、 Control standard for cable tray construction process 2.1.

3.3.2 The shielding layer of shielded cable, conductor and compensation conductor shall be grounded according to the design or manufacturer’s requirements.

3.2 Cable laying 3.2.1 Before cable laying, the overall planning of cable routing shall be carried out.

3.2.9 Cables shall be fixed at the following places: 3.2.9.1 Cables laid vertically or laid at an inclination of more than 45 ° shall be placed on each support at every 2m of the bridge.

3.1.2 Before the installation of the cable trench formwork, the cable embedded pipe laying construction shall be completed to avoid the impact on the civil construction quality due to the cable trench drilling and pipe laying.

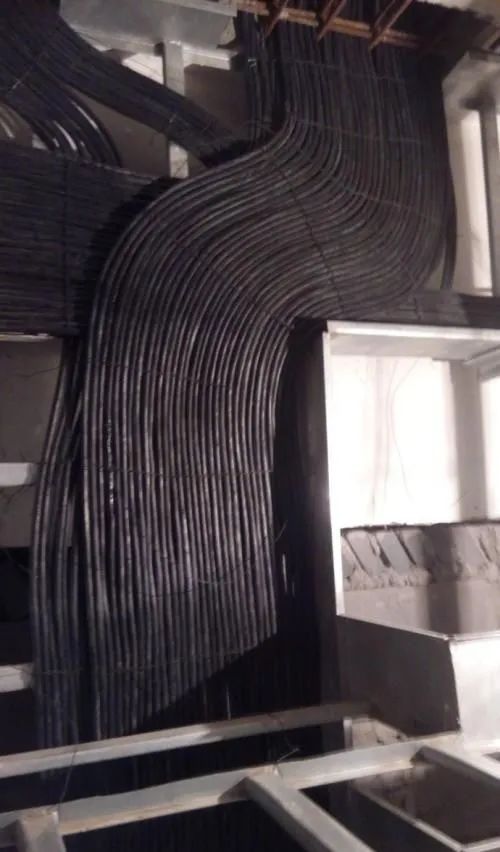

Cables of the same route shall be laid uniformly.

3.2.4 The cable shall be led out from the cable rack with a hole opener, installed and fixed with cable pipe by welding, and connected with a flame-retardant hose connector.

3、 Control standard for cable laying and wiring construction process 3.1.

The cable plate shall not be clamped in the cable, but shall be firmly tied and arranged outside the cable.

2.3.

For the cables with more lead wires under the cabinet and panel, vertical cable bridges can be added in the cable interlayer to make the lead wires of the cables more orderly and beautiful.

The corbel on the same layer shall be on the same horizontal plane, and the height difference shall not exceed ± 5mm.

3.3.3 Cables leading into panels and cabinets shall be arranged in order, numbered clearly and fixed firmly.

Cables in the same channel shall avoid crossing.

3.1.3 In addition to the construction according to the drawing, the actual position of equipment wiring shall also be taken into account to ensure that the cable embedded pipe is buried in place at one time, so as to avoid the impact on the appearance of the cable lead wire due to the position deviation of the buried pipe.

The bending radian of the cable core shall be neat and consistent.

For armored cables, the steel tape shall be fastened with hoops.

The protective pipe end shall be thermoplastic pipe instead of hose connector.

2.2 The supports and hangers are generally directly welded to the embedded parts, and no embedded iron can be fixed with expansion bolts.

3.3.4 The length of control cable head shall be consistent.

The leading part of the cable core is arranged in rows, and the binding tape is neat and uniform.

3.2.8 When handling cables, the cables shall not be loose, and the cable reel shall roll in the direction indicated by the arrow on the cable reel.

The cable laying shall follow the design route.

The bending radian of the secondary wiring core shall be consistent, and the length of the wiring rubber head shall be consistent.

3.2.10 The speed of mechanical cable laying shall be no more than 15m/min, and the traction strength shall be no more than 7kg/mm2 to prevent the cable from mechanical damage.

If it cannot be reached, thermal insulation protection measures shall be taken.

3.2.6 The cable shall be bound and fixed by combining the braiding of binding tape with the crimping of clamps (that is, the special hot dip galvanized fixing clips for processing cables in rows and the hook type screws ordered to fix the cables), so that the cables are arranged in rows and layers, horizontal and vertical, neat and beautiful.

Before construction, the regional division of labor and technical disclosure shall be carried out for the wiring workers to make the wiring construction consistent in the process style.

Determine the path, location, number of layers and specifications of cable tray according to the drawings of the design institute, cable laying list and site conditions.

The height of pipe orifice can be ensured to be consistent by connecting pipe or level, and the cable can be embedded in rows and rows by pulling wire.

3.2.9.2 Cables laid horizontally shall be located at the head and end of cables, turns and both ends of cable joints.

3.1.4 The buried height of cable embedded pipe shall be basically the same, and the perpendicularity deviation shall be ≤ 2mm; In addition to laying cable embedded pipes in rows at the same location, laying cable embedded pipes in the same row and column is also required to be arranged in rows, neat and standard.

3.2.3 The temperature of the cable laying area shall not be higher than the allowable long-term working temperature of the cable.

It shall be arranged vertically or horizontally regularly.

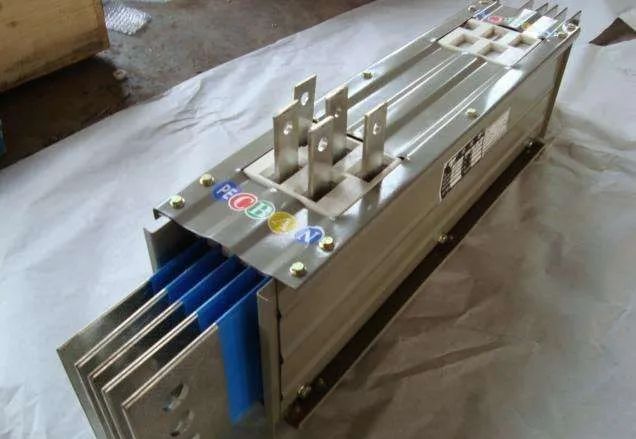

1.2.1 The panel and platform base are connected to the grounding grid, and the panel and platform are grounded by the single point grounding of the grounding box.

When pressing elbows, special hydraulic pipe bender is used to ensure the quality of cable embedded pipe bends.

3.3.

1、 The installation process control standard of panel, console and switch cabinet 1.1 The panel base shall be made according to the design drawings and the manufacturer’s data and dimensional error requirements.

3.2.5 During the cable laying construction, the cable shall be temporarily bound, and the cables with the same route shall be uniformly arranged and fixed after being laid to make them neat and beautiful.

Embedding of cable embedded pipe 3.1.1 Procurement of national standard galvanized steel pipe.

3.3.8 The cable core rubber insert number shall be printed with the special printer for cable rubber insert, and the length shall be consistent with the insertion direction..

The spare cable core shall be uniformly reserved to the highest position of the terminal.

The fixing bolts of cable support and bracket shall be in a uniform direction, horizontal and vertical.

The binding distance shall be even and the spacing shall be 100~120mm.

The length of the spare core shall be reserved with appropriate allowance.

3.2.2 High and low power cables, strong current and weak current control cables shall be configured from top to bottom according to the specification.

1.2.2 After the panel and platform are erected, they must be wrapped to prevent dust from entering the panel and burning the card during operation.

After the armored cable enters the panel and cabinet, the steel strip shall be grounded.

It is better to draw a section diagram of the routing, that is, how many cables pass through a certain point.

The cable support shall be obviously grounded and well grounded.

1.2 The process standard of the vertical plate shall meet the requirements of the equipment manufacturer.

Special attention shall be paid to the control of the cable wiring process in the building cabinet, and first-class wiring workers shall be arranged to take charge of this part of wiring work.

3.3.7 The cable core shall be firmly connected, and enough spare length shall be reserved.

3.3.5 After the control cable is connected, the cable core shall be straightened and arranged in order.

3.2.7 For the cables between control cables, in addition to the above requirements, the cables from the lead wire to the bottom of the control panel shall be arranged into a round bundle, with smooth bending, consistent bending radius and in accordance with the specification requirements.

When the cable is laid in parallel with the outer surface of the pipe insulation layer, its spacing shall be greater than 500mm, and when it is crossed, it shall be greater than 200mm.

Multi strand core pressing nose, with the nose exposed 0.6~1mm.

The steel structure can be directly welded and fixed, and the welding parts shall be painted again after installation.