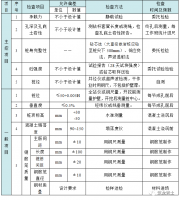

The practice of grounding embedded connecting plate ⑴ The first practice of grounding embedded connecting plate ⑵ The second practice of grounding embedded connecting plate: 2.

Source: In case of infringement of electromechanical contacts, please delete this article to introduce some common construction and installation practices in building electricity: 1.

⑵ B Photo The cable passes through the hole on the wall, and the gap is filled with blanking material.

The concealed installation of the breaking clip and the installation of the grounding resistance detection point 5 Detailed treatment of the connection between the roof lightning strip and the downlead: ⑴ At the connection between the downlead and the lightning strip, the rebar head of the downlead should be polished into a semicircle, as shown in the following figure.

(5) The equipotential of the metal window frame can also be connected with the embedded parts of the ring beam or column main reinforcement from the top or side of the window frame, and the connector can be 25 × 4 galvanized flat steel or φ 10 round steel.

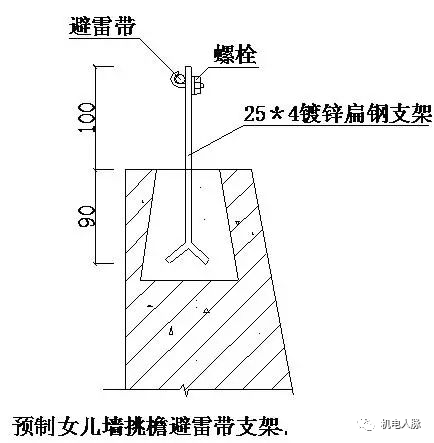

(2) The installation method of the prefabricated parapet cornice lightning strip bracket is shown in the following figure: ⑶ The installation method of the parapet cornice lightning strip bracket fixed with expansion bolts is shown in the following figure: ⑷ After the parapet cornice is wrapped with stone and other decorative materials, the fixing method of the lightning strip bracket on the stone is shown in the following figure: ⑸ The installation method of the roof lightning strip bracket on the prefabricated concrete block: 4.

Grounding installation of low-voltage cable buried cable incoming line 11.

Trapezoid Rubber Magnetic Chamfer

Fire blocking and sealing method for cable through wall holes ⑴ In Figure A, the holes on the wall are sealed with fire protection bags, and cables pass through the fire protection bags.

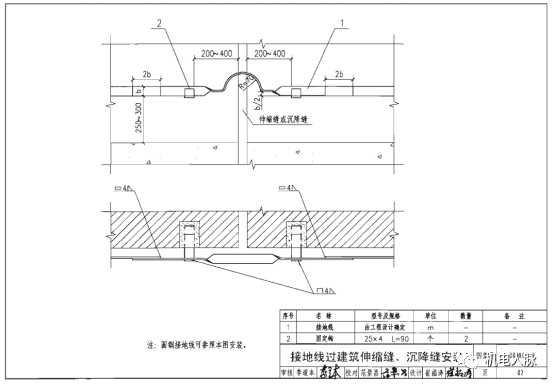

(3) The lightning strip and grounding bus shall be made into semicircle when passing through settlement joints and expansion joints according to the following figure, which not only ensures the appearance but also meets the lightning protection and grounding requirements.

15.

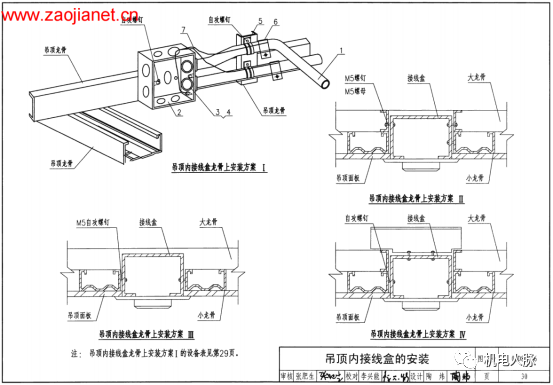

When embedding, place the junction box ring on the pre-drawn lamp position, and then lower the pipe, so that the length of the pipe into the box can be controlled well.

Installation method of distribution box on light partition board 13.

According to the actual situation of the distribution shaft, a set of cable clamps can be installed 300 mm above and below the branch joint of the main cable, and between the lower cable clamp and the floor.

The levelness and perpendicularity of the row of lightning strip support shall be checked one by one by pulling a line.

3.

⑶ When the lightning strip is connected with the downlead, the welding shall be conducted on both sides, and the welds shall be smooth and full.

⑵ Allowance shall be reserved when the lightning strip and grounding bus pass through the settlement joint and expansion joint to avoid breaking the lightning strip or grounding bus in case of deformation.

(3) When the civil engineering starts to bind the cover bar, the pipe orifice shall be plugged and the box shall be plugged, and then the box bottom shall be covered, and the box bottom shall be spot welded on the box ring with electric welding at the opposite corners of the box.

The grounding wire shall pass through the door and the grounding branch shall be installed When the window is close to the steel column, one end of the connecting conductor can be directly welded to the steel column.

18.

This method can greatly shorten the time between binding bottom reinforcement and binding cover reinforcement when cooperating with the main civil construction.

⑶ B in the figure is the diameter of the cable.

9.

Installation method of electrical conduit box during rapid embedding (applicable to connection of welded steel pipe and steel junction box) ⑴ During production of steel junction box, the bottom and ring of junction box shall be separated, The holes on the ring shall be knocked according to the inlet and outlet of the pipeline in the drawing, and the junction box shall not be knocked randomly.

⑶ φ The welding length between 10% metal round steel and steel bars or window frames and other building metal components shall not be less than 60mm.

Detailed installation method of lightning strip support (1) The installation method of cast-in-place parapet cornice lightning strip support is shown in the following figure.

⑵ There is no need to plug the junction box before embedding.

⑵ The section between the parapet and the lightning strip of the downlead shall be painted with red paint to make obvious marks.

Secondly, the connection between the box and the pipe and the grounding jumper wire need not be worried about burning the pipe plug when welding, which can ensure the reliable connection between the pipe and the box and the grounding connection between the pipe and the box.

During the lightning protection inspection and acceptance, the lightning protection downlead is very conspicuous.

⑵ The design principle of the main cable clamp is to install one set every 1.5m.

⑷ Lap plate shall be embedded and can be bolted or welded to window frame or door frame.

It can be seen from a glance that this is the downlead point, as shown in the following figure.

6.

19.

Embedded method of embedded installation of distribution box in wall 12.

Each layer is evenly distributed.

Lightning strip, grounding connection bus over settlement, expansion joint installation practice ⑴ Lightning strip, clip, flat steel should be galvanized.

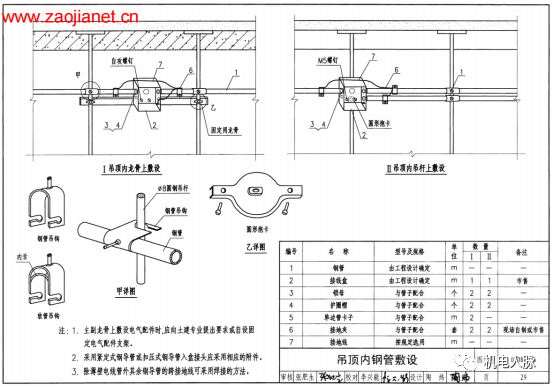

Construction method of steel pipes and junction boxes in the ceiling 16.

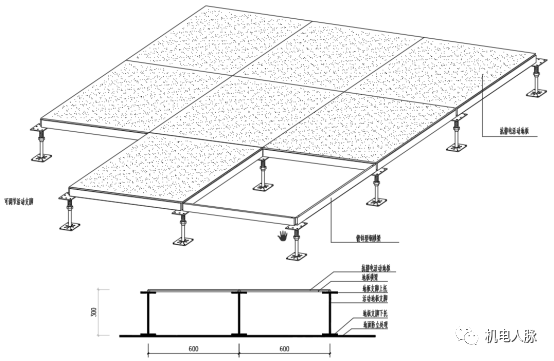

Simple practices of anti-static flooring in the computer room ▼ More wonderful recommendations, please pay attention to our ▼ sharing points and favorite points..

The grounding wire shall pass through the building settlement, and the expansion joint shall be installed.

The flat steel support shall be closely coordinated with the civil engineering specialty during installation.

7.

Installation of pre branch cables ⑴ Pre branch cables are divided into two types: multi-core and single core cables (when the pre branch power cable trunk cable adopts single core cable, anti eddy current effect shall be considered, and magnetic conductive metal clamps are prohibited).

Construction method of pipelines passing through expansion settlement joints in the ceiling 17.

Equipotential connection construction method of metal door 10.

Open installation method of distribution box on square steel column 14.