5.

Waterproof layer The waterproof layer of the roof shall be made of polyurethane waterproof film with a thickness of not less than 2mm or elastomer modified asphalt waterproof roll with a thickness of not less than 4mm or modified asphalt polyethylene tire waterproof roll.

Quality control point 1.

Sealing around roof pipe and fillet, waterproof additional layer 4.

and the surrounding sealing are completed, the roof slab shall be subjected to the structural water closing test and the leakage shall be repaired.

The insulation layer shall be made of hydrophobic insulation materials, such as extruded polystyrene board (XPS), and the roof slope shall be preferably made of structural slope.

6 When the slope layer is used for slope making, lightweight concrete shall be preferred.

2.

The light concrete shall be used for the sloping layer of the flat roof.

The water storage depth at the top of the roof shall be 30-50mm, and a specially-assigned person shall be arranged to check and record the leakage.

See the design for thickness and slope.

Waterproof construction quality control 5.

See the instructions of the roof for the waterproof layer.

In order to improve the performance of roof self-waterproofing, in addition to determining structural reinforcement according to structural calculation, no less than Ф 8@150-200 Two-way reinforcement mesh is used to control the cracks on the slab surface and improve the self-waterproof performance of the structure.

8 Rigid protective layer 40mm thick C25 fine aggregate concrete protective layer, with internal Φ L5 @ 200 single-layer two-way reinforcement mesh, vertical and horizontal spacing ≤ 3000mm, and the parapet is 300 mm out, with a dividing joint of 20 mm wide, embedded with SBS modified asphalt paste, and the reinforcement at the dividing joint is broken.

The waterproof additional layer shall be turned up from the internal corner and extended horizontally for no less than 250mm.

Sealing around pipe root, rainwater inlet and exhaust duct 2.

After rectification, the water shall be closed again until there is no leakage.

In addition, construction measures such as reducing the slump of roof concrete, concrete pouring and tamping, surface compaction and polishing will improve the waterproof performance of the roof.

When the roof slope is greater than 45 °, a closed formwork shall be set up at the upper part to prevent the concrete from being difficult to pour or not compacted due to excessive collapse.

The reinforced concrete roof slab shall be made of concrete with small slump as far as possible on the premise of meeting the construction conditions; The roof concrete must be poured and compacted to ensure the impermeability of the main structure; When pouring concrete, the roof slab shall be leveled and calendered with the original slurry.

In case of leakage, find out the cause and rectify it.

Concrete for pitched roof The concrete for pitched roof must be poured and compacted.

3.

After the installation of various roof pipes, exhaust ducts, rain inlets, etc.

The waterproof additional layer should be turned up from the internal corner and extended horizontally not less than 250mm.

in the middle and out of the roof and the surrounding sealing, and the structural closed water test shall be carried out and the leakage shall be repaired.

2.

7.

After the construction of the waterproof layer for the closed water test of the flat roof is completed, the rainwater inlet shall be temporarily blocked, and the 24-hour closed water test shall be carried out.

The water storage depth at the top of the roof should be 30-50mm, and special personnel should be arranged to check and record; If leakage is found, the cause shall be analyzed and rectified.

Additional waterproof layer shall be added at the root of parapet wall, pipes out of the roof, exhaust duct, rain inlet and other internal corners.

and the surrounding sealing are completed, the roof slab shall be subject to the structural water closing test and the leakage shall be repaired.

After the rectification is completed, the water shall be closed again until there is no leakage.

3.

The thermal insulation and energy conservation of the insulation layer shall be subject to the energy conservation design special section of the construction drawing.

.

After the construction of the waterproof layer of the sloping roof is completed, it will be led to the top of the sloping roof for watering, and the watering time shall not be less than 2h or check after the heavy rain.

6.

The internal corners such as the partition joint and parapet wall, and the equipment pipe foundation shall be provided with a 1mm thick two-oil polyurethane waterproof layer, and the internal corners such as the partition joint and parapet wall shall be provided with a 500mm wide practice description and node detail practice description: this practice is applicable to the anti-leakage treatment of the flat roof.

5 isolation layers and 3 color cloth isolation layers (or see the design description for details).

8.

Roof rigid protective layer The spacing of the rigid protective layer on the roof surface shall not be greater than 3m × 3m to facilitate the free shrinkage of concrete, and there is no uncontrollable crack between the dividing joints.

2.

If it is designed as thermal insulation board, it shall be preferentially paved with mortar staggered joints, and ensure its smoothness and firmness.

The flat roof closed water test and structural repair shall be carried out after the installation of the pipes, exhaust ducts, rain inlets, etc.

4 After the construction of the waterproof layer of the closed water test, the rainwater inlet should be temporarily blocked, and the 24-hour closed water test should be carried out.

If any leakage is found, the cause shall be analyzed and rectified.

Section II Anti-leakage method of roof: inverted single-layer anti-horizontal roof process flow and detail method 1.

After the installation of various roof pipes, exhaust ducts, rain inlets, etc.

If the slope making layer is used for slope making, the slope shall not be less than 2%.

Sorting | Douding construction Section I Description of roof leakage prevention practice 1.

The dividing joint is embedded with SBS modified asphalt paste.

All the pipes, exhaust ducts, walls and other internal corners that cross the roof or the roof shall be plastered with cement mortar to form a fillet with a radius of not less than 100mm.

4.

7.

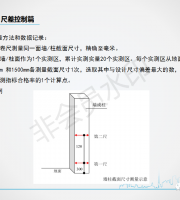

Breather pipe installation quality 7 Process flow and details of rigid protective layer and grid joint upright flat roof: 1.

Closed water test 6.

Structural closed water test 3.

The material and practice of the waterproof additional layer are the same as that of the waterproof layer.

Self-waterproofing of roof structure of roof panel structure is an important part of roof waterproofing.

3.

The thermal insulation and energy conservation of the insulation layer shall be subject to the special section of energy conservation design in the construction drawing.

The roof adopts the inverted system with the insulation layer above the waterproof layer, which can protect the waterproof layer and extend the service life of the waterproof layer.

9.

Additional waterproof layer shall be added to the root of parapet wall, pipes out of the roof, exhaust duct, rainwater inlet and other internal corners; The material and practice of the waterproof additional layer are the same as that of the waterproof layer.

The reinforced concrete roof slab shall be made of concrete with small slump as far as possible on the premise of meeting the construction conditions; The roof concrete must be poured and compacted to ensure the impermeability of the main structure; When pouring concrete, the roof slab shall be leveled and calendered with the original slurry.