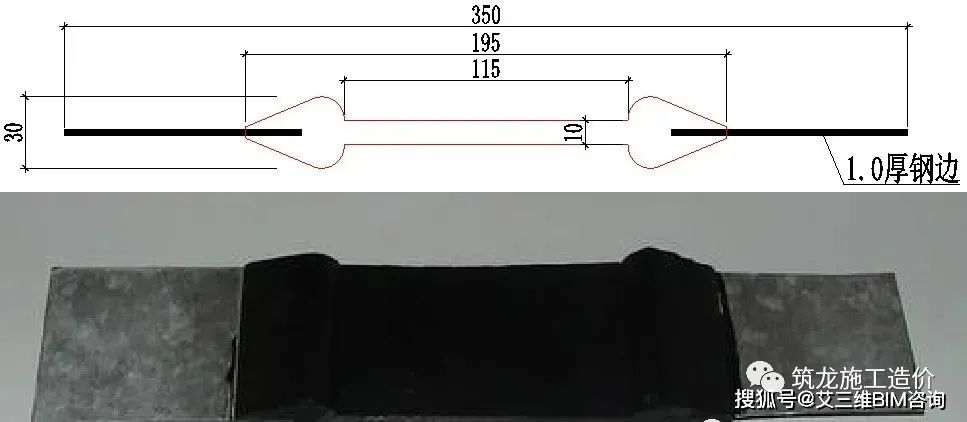

When the temperature display of the temperature controller reaches the specified temperature (135~160 ℃), the red light of the temperature controller lights up, and the power is automatically cut off, At the same time, record the curing time, which is determined according to the thickness of steel edge waterstop (350 × The curing time of 10mm steel edge waterstop is 30~15min) (4) After the curing time is reached, disconnect the power supply, conduct hot vulcanization butt joint on the mold site, 2 cold butt joint (1) place a U-shaped hoop on the steel edge of both ends of the waterstop, and use the electric hand drill to drill holes according to the hole spacing of the U-shaped hoop (2) outside the riveted U-shaped hoop, Wrap a circle of 2.0mm thick unvulcanized butyl rubber putty sheet horizontally along the steel edge waterstop to bond butyl putty sheet (3) Stick a layer of 2.0mm thick rubber sheet outside the unvulcanized butyl rubber putty sheet to bond the rubber waterstop to cold joint on site~~Recommended reading~~What are the contents of the unit project construction organization design? Concrete rebound, strength conversion and construction method analysis of waterproof mortar for building exterior wall..

1.

2.

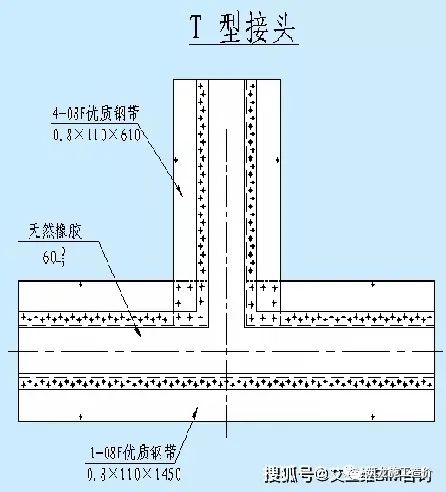

Examples of type of steel edge rubber waterstop Construction joint Flat webbed type mid buried waterstop Deformation joint Mid hole type mid buried waterstop Deformation joint Mid hole type externally attached waterstop Setting method of steel edge rubber waterstop Setting method of plane deformation joint waterstop Setting method of vertical deformation joint waterstop Example: hanging method of externally attached and mid buried waterstop Pre setting steel edge rubber waterstop Joint type Steel edge rubber waterstop Various joint examples: waterstop cross connection The steel edge rubber waterstop of the head can be connected in two ways: on-site vulcanization and cold connection.

Set external rubber waterstop on the upstream; Middle buried waterstop is set in the middle of the structure.

It is mainly used for the construction of deformation joint of underground waterproof engineering construction joint, giving full play to the characteristics of both waterstop and steel edge.

On the other hand, the galvanized steel edge has good adhesion to the concrete, so that the waterstop can withstand greater tension and torque, so as to ensure that the rubber waterstop will not loose and fall off within the effective deformation range of the concrete, and improve the waterstop effect.

The steel edge rubber waterstop has dual functions.

Steel edge waterstop, that is, steel edge rubber waterstop, is composed of rubber waterstop and steel edge.

The process flow is as follows.

Hot vulcanization butt joint (1) fix the U-shaped hoop on the steel edge with rivets (2) put the required rubber into the reserved gap of the waterstop, cut the rubber size according to the reserved gap size, cover the mold, and then tighten the bolts to put the rubber into the reserved gap, cover the mold, and tighten the bolts (3) switch on the power supply.

The joint of rubber waterstop shall be butt joint type instead of lap joint type.

It is more waterproof and bears more uniform and reasonable force.

3.

Key points for application of steel edge rubber waterstop: 1.

The deformation joint shall adopt the middle hole type; The construction joint shall be flat type.

On the one hand, it can extend the path and slow down the water seepage speed.

Field vulcanized joint is preferred, and cold butt joint can be used.