▼ After the point position of the wire box is determined, the slotting and snapping work shall be completed according to the number of pipes.

The distance between wire tubes shall be ≤ 10mm.

▼ Implement the data such as insulation construction interface and construction surface thickness, take the 1m control line on site as the standard, and conduct site positioning according to the curing map point and elevation parameters.

Use laser level, leveling ruler and steel tape to check the elevation, flatness and spacing of wire boxes.

Quality inspection 1.

For the construction points of each process, the following construction site example is shared for reference and exchange.

The connection between the wire tube and the wire box must be equipped with a lock catch; Burrs at the line pipe interface must be removed; The joint position between the line pipe and the line pipe must be bonded with glue; A spacing of ≤ 10mm shall be reserved between the line pipe and the line pipe, and between the line pipe and the groove wall, to ensure the compactness of the filling and avoid the existence of hollowing and cracking quality hazards.

Key points of the construction procedure ▼ Clean the path of the once embedded conduits to ensure the smoothness of the conduits.

▼ Threading construction and finished product protection.

2.

The general process of secondary reserved and embedded construction is: primary pipeline cleaning → wall slotting operation → positioning, installation and fixation of wire box → laying, installation and fixation of wire pipe → lead and threading work → finished product protection work.

It is forbidden to cut structural reinforcement.

3.

Use a steel tape to check the installation spacing of the conduits in the trunking.

▼ Use the cutting machine to cut along the line, and finally tick to complete the opening of the trunking (note: the groove depth ≤ d+20mm, and the groove width ≤ dn+60).

4.

▼ The bottom boxes of strong and weak current boxes shall be inserted and embedded immediately after the completion of civil plastering and raking; The installation finished surface shall be flush with the civil plastering finished surface; If the wall surface of thermal insulation construction is involved, the completed surface of the bottom box shall be flush with the completed surface of thermal insulation construction (Note: the lock catch shall be installed in place in advance when the bottom box is embedded).

In the same room, the error between the wire boxes at the same elevation shall be controlled within ± 2mm, and there shall be no obvious visual quality defects.

The error of wire boxes in the same room and at the same elevation is <± 2mm.

▼ After the junction box is firmly fixed, complete the laying and installation of the conduit.

Transferred from: click on safe construction technology“.

3.

▼ After the wall plastering and raking are completed by the civil engineering discipline, the wire box installation and fixation can be carried out.

After the completion of embedded installation, the closing and sealing of the opening shall be completed immediately.

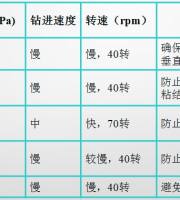

Problems on the site ▼ Site clearing system is not implemented in place ▼ Impact of drilling shear wall holes on the structure Precautions for secondary embedding of shear wall 1.

The bonding of direct joints must be firm and reliable, and the bonding quality shall be spot checked on site.

It is prohibited to use cutting machine to cut at the shear wall location.

It is prohibited to complete the wire box fixation in advance without raking the wall.

▼ During the piping installation of the strong and weak current boxes, the line pipes shall be kept as straight as possible, and the spacing between the line pipes and between the line pipes and the groove wall shall be no less than 10 mm to ensure the compactness of the filling and avoid the existence of hollowing and cracking quality hazards (suggestion: whether the secondary mold closing pouring is carried out because the strong and weak current boxes are densely located with line pipes).

2.

After the installation of the junction box and conduit, use foam to fill and protect the junction box, so as to avoid the blockage of the pipeline due to plastering construction and other reasons.

▼ During the positioning and installation of the junction box, carefully check the point position and positioning size of the curing diagram.

The installation height of the wire box at the shear wall position is consistent with the curing diagram, and the left and right size deviation is ≤± 30mm.

It is strictly prohibited to slotting at will without snapping the line (Note: slotting depth ≤ d+20mm, slotting width ≤ dn+60).