▲ Line color separation ◎ The output terminals of the main and sub distribution boxes should be crimped and terminal posts, and the output terminals of the switch boxes should be ZM14-ZM13 sockets.

◎ Overhead lines must have overload protection.

In addition, as the leakage switch generally has the function of air switch, it can also be used as an overload protection appliance..

◎ The third level end switch moving box must be equipped with disconnectors, leakage protectors (action current 30mA or 15m action time 0.1s) with N rows, PE rows with incoming and outgoing line clamps, and electrical components must be fixed on the insulating plate.

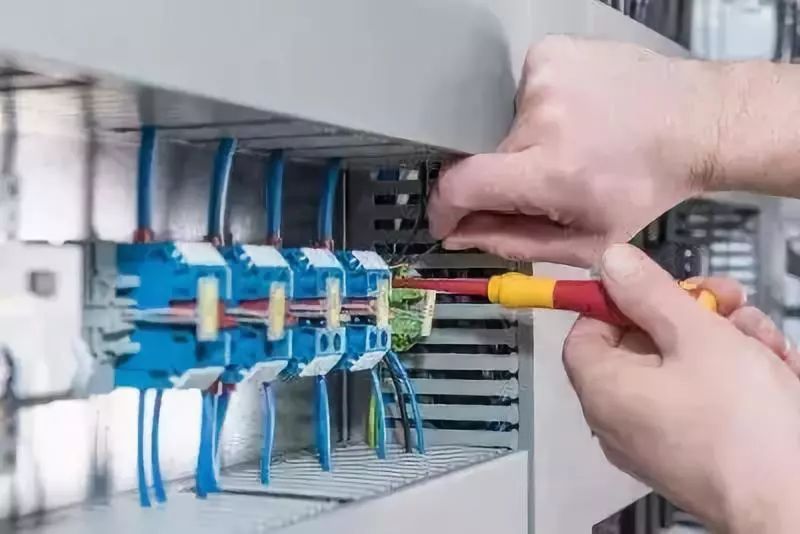

◎ L1, L2, L3, N and PE wires in the electric box must be color separated, and their colors are yellow, green, red, light blue and green/yellow.

▲ The three-level power box ◎ switch shall be distributed by the three-level power box.

It is strictly forbidden to connect the power cord entering the switch box with a pin.

The distance between distribution boxes shall not be more than 30m.

The rated value and action setting value of the main switch shall be consistent with the rated value and action setting value of the shunt switch.

It is not allowed to hook up other temporary electrical equipment.

Any of the following over protection appliances can be adopted: 1) Automatic air circuit breaker (air switch), its overload tripping current setting value.

◎ Each electric equipment shall have its own special switch box, and the system of “one machine, one switch, one leakage and one box” must be implemented.

◎ The overhead line shall be set on the special pole, and the distance between pole supports of wire rope wiring shall not be greater than 12M.

It is forbidden to directly control ≥ 2 sets of electrical equipment (including sockets) with the same switch box.

◎ Power distribution box and lighting box should be set separately.

The switch box is used to control the horizontal distance of fixed equipment not more than 3m.

▲ “One machine, one switch, one leakage box” shall be implemented on the construction site ◎ The switch box must be equipped with a leakage protector that meets the standard.

The distribution box shall be numbered, indicating its name, the name of the electrician on duty and the maintenance telephone number.

▲ Line installation in the electrical box ◎ The power switches and electrical appliances in the distribution box and switch box shall be firmly installed without deflection and looseness.

Regulations on cable laying ◎ Insulated copper wires must be used for overhead lines, and bare wires are strictly prohibited.

Specifications for configuration and use of distribution box and switch box ■ Distribution box ◎ Primary main box is equipped with metering meter, ampere voltmeter, main power supply disconnector, shunt disconnector, leakage switch, and grounding neutral bar.

The inlet and outlet of the conductor in the box shall be at the bottom of the box.

The rated leakage action current of the leakage protector in the switch box is ≯ 30mA, and the rated leakage action time should be less than 0.1S.

2) Fuse.

Insulated wires shall be used for connecting wires, which shall be arranged neatly without exposed live parts.

The working zero line in the switch box of the electrical box shall be connected through the terminal board.

It shall be set at the load side of the power disconnector and the load side of the power disconnector in the switch box.

1.

On site, except that overhead lines can be used for incoming lines of the main box, five core cables are used for the rest.

Live working is strictly prohibited.

▲ During the inspection and maintenance of the secondary no-load voltage reduction and electric shock protector ◎ electric box, the corresponding power switch of the previous level must be switched off and powered off, and the power failure sign board must be hung.

◎ Distribution box and switch box shall be set in dry, ventilated and normal temperature places, otherwise corresponding protective measures shall be taken.

◎ The secondary distribution box shall be equipped with the main power disconnector, shunt disconnector, and the circuit breaker socket shall be fastened on the insulating board according to the specified position, and shall not be skewed or loosened.

The inlet and outlet wires shall be sheathed, bundled and made into waterproof bends.

Implement the national laws and regulations on safety production, implement the JGJ46-2005 standard of technical specification for safety of temporary electricity use on construction site, implement the company’s safety production management system, ensure the safety of electricity use on project construction site, prevent electric shock and electrical fire accidents, and formulate regulations on temporary electricity use on construction site.

(If there are local requirements, the local requirements can be implemented) ■ Power requirements for the construction site ◎ Three level power distribution system shall be adopted; ◎ TN-S grounding protection system is adopted; ◎ Adopt secondary leakage protection system; ◎ Implement the system of one machine, one switch, one box and one leakage.

The action current and action time of the leakage protection in the two-level distribution box shall be matched, so that it has the function of staged and sectional protection.

Power distribution system diagram shall be pasted in the box, indicating electrical component parameters and shunt names, with inspection records, and the use of reverse switch is strictly prohibited.

◎ The switch box of electric welding machine shall be equipped with secondary no-load voltage reduction and electric shock protector.

2.

▲ The electrical box shall be kept clean and specially assigned person shall be responsible for it.

The installation board must be equipped with a terminal board for special protection neutral connection, and each terminal post ≯ 2 lines.

When the operation is stopped at the construction site for more than 1h, the power box shall be powered off and locked.

If they are combined in the same distribution box, the power and lighting lines should be set in separate circuits.

▲ Line installation in the electrical box ◎ The electrical appliances in the electrical box must be reliable and intact.

◎ No sundries shall be placed in the distribution box and switch box, and they shall be kept clean.

There should be enough space and passage for two people to work at the same time around the electric box, and it is not allowed to stack any articles that hinder operation and maintenance.

◎ The main disconnecting switch and shunt disconnecting switch, as well as the main fuse and shunt fuse (or the main automatic switch and shunt automatic switch) shall be set in the electrical box.

Multi strand wires shall be cold pressed or tinned.

Damaged and unqualified electrical appliances are not allowed to be used.

■ Specifications for configuration and use of switch box ◎ The power distribution system shall be equipped with a general distribution box and a sub distribution box for sectional and layered distribution.

When the fuse of the electric box is replaced, it is strictly prohibited to replace it with a fuse that does not conform to the original specification.

It is strictly prohibited to use four core cables plus a PE wire to replace five core cables on site.

Electrical components shall have product certificates and be included in the technical archives.

The metal box of the distribution box, the switch box, the metal electrical installation plate and the non live metal base and shell of the electrical appliances in the box must be connected to the neutral through the terminal board.

The main circuit and branch circuit of the distribution box must be equipped with obvious disconnection points.

The rated fusing current value of the melt is ≤ the safe current value of the protected line conductor.