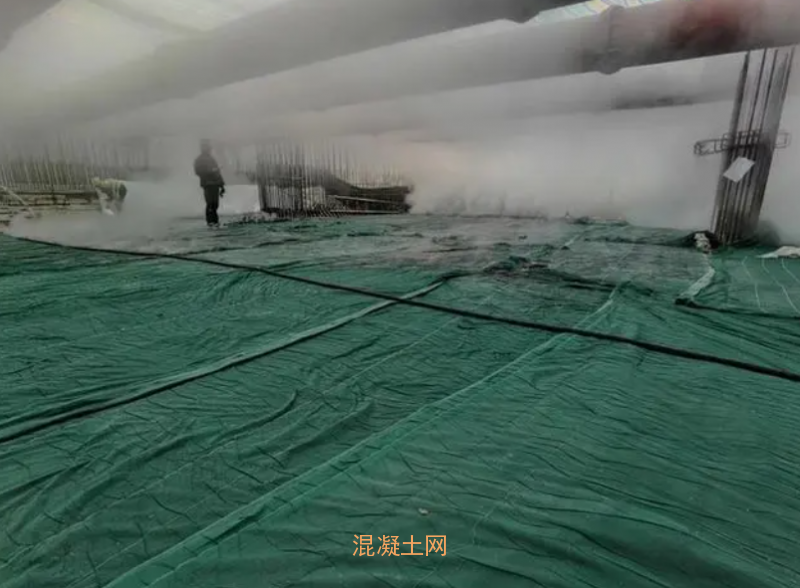

The application of “steam technology” is just a microcosm of strict engineering quality management.

The concrete cured by “steam technology” is used in winter pouring, and the construction quality has been greatly improved.

Dry and cold weather is a difficult problem for subway construction in winter.

Since the commencement of construction, the General Contracting Project Department of China Railway Shanghai Investment Corporation has comprehensively improved the quality management level by organizing all participating units to carry out special activities such as project tackling, technical competition, process inspection and typical observation.

The electric steam curing method uses special equipment to burn the water to a certain temperature through electric heating, so that the water evaporates to form steam.

After the technical breakthrough made by the construction participants, through scientific tests and analysis, it was finally decided to adopt the electric steam curing method to improve the concrete curing quality in winter.

In order to solve this winter construction problem and ensure the quality of concrete construction, the General Contracting Project Department of China Railway Shanghai Investment Corporation and the Civil Work Zone 12 of China Railway Beijing Engineering Bureau organized in-depth research, repeated comparison and demonstration, and found the best concrete winter curing method suitable for Jinan construction conditions.

This is the new and interesting “steam technology” of Jinan Metro Line 6, which plays a significant role.

Compared with the traditional thermal storage maintenance and coal-fired steam maintenance, the electric steam maintenance method has three outstanding advantages: first, it is safe and environmentally friendly, and will not cause air pollution; The second is high efficiency.

As we all know, under normal conditions, water will freeze when the temperature drops to about 0 ℃, and this is what concrete is most afraid of.

Focus on details to improve quality, and create high-quality products with ingenuity.

However, in a construction site of Jinan Rail Transit Line 6, there is such a “hot soil”: in a closed space, the temperature is kept at 12 to 15 ℃, and the inside is “smoky”, warm and humid.

It is not people who enjoy the “warm winter”, but concrete.

Core tip: Dry and cold weather is a difficult problem for subway construction in winter.

This advanced construction method, known as “steam technology”, was first applied to the construction of Jinan rail transit.

In the next step, we will promote the application and optimize the electric steam curing method in the conditional work areas along the line, effectively improve the winter construction quality, and continue to improve the quality management and technical innovation level from the daily construction to help the construction of high-quality projects..

In order to solve this winter construction problem and ensure the quality of concrete construction, the General Contracting Project Department of China Railway Shanghai Investment Corporation and the Civil Work Zone 12 of China Railway Beijing Engineering Bureau organized in-depth research, repeated comparison and demonstration, and found the best concrete winter curing method suitable for Jinan construction conditions.

When the water in concrete freezes, its volume will increase, seriously damaging the concrete structure, causing it to become loose, presenting a state that everyone often sees as “breaking at the touch”.

Jinan is dry and cold in winter, and the outdoor temperature can sometimes reach below – 10 ℃.

When the water in concrete freezes, its volume will increase, seriously damaging the concrete structure, causing it to become loose, presenting a state that everyone often sees as “breaking at the touch”.

As we all know, under normal conditions, water will freeze when the temperature drops to about 0 ℃, and this is what concrete is most afraid of.

Compared with other curing methods, it can shorten the “equal strength” time of concrete for 2-3 days; Third, the effect is good.

When the steam generates a certain pressure in the boiler, it is released in the closed space of the working face through pipes, and the formed hot steam provides a suitable temperature and humidity for the hardening of the concrete structure.