Personnel and mechanical equipment preparation 1) Personnel preparation includes the management personnel of the project management department and the management personnel of its cooperation team, as well as the on-site mechanical operators and workers.

Preface: Before introducing the construction of subgrade earthwork, we should first consolidate the basic structure of the subgrade through a map.

The platform intercepting ditch shall be set outside the falling platform.

The surface of paddy field sections shall be cleaned until the bearing capacity of the foundation is qualified.

After the completion of cutting excavation, slope protection and side ditch construction shall be arranged immediately, and the roadbed shall be leveled according to the design elevation.

.

3) These include excavators, loaders, bulldozers, graders, road rollers, dump trucks, sprinklers and other small machines and tools.

Trapezoid Rubber Magnetic Chamfer

Regardless of the excavation quantity and depth of the slope, the excavation shall follow the principle of top to bottom.

The superelevation transition is excavated in the transition curve.

3) After the surveyor has placed the pile position, the site technician shall protect the pile position to prevent the loss and displacement of the pile position.

2) Before the commencement of the subgrade, the subgrade center setting out shall be carried out, the slope toe setting out shall be carried out again for the filling section according to the slope, and the side line setting out of the slope excavation line shall be carried out for the excavation section according to the slope gradient.

2) The cutting excavation shall be measured and set out according to the design section, and the slope shall be smooth and stable without losing slope and the curve shall be smooth; The subgrade surface shall be flat, the upper slope shall be free of loose stone, the side line shall be straight and smooth, and the curve shall be smooth.

The falling platform shall be set according to the drawing.

Cutting excavation (construction method considers depth, length, terrain, soil quality and other conditions): short and deep cutting: full width of cross section, full section transverse excavation method △ full section transverse excavation method longer cutting: layered longitudinal excavation: full width of cross section, longitudinal layered excavation of channel longitudinal excavation: excavation of a channel along the longitudinal direction, and then excavation of both sides of mixed excavation method: excavation of the channel along the longitudinal direction, and then excavation of △ longitudinal excavation method 1) side ditch and its intercepting and drainage facilities, The setting out shall be carried out according to the design drawing.

The earthwork volume shall be calculated and compared with the construction drawing to find out the difference from the design, and verify whether the engineering quantity is consistent with the drawing.

2) Equipment preparation includes mechanical equipment and instruments that can be used in actual construction.

Survey preparation 1) Before the commencement of the subgrade, the traverse survey shall be carried out first, and then the cross section of the subgrade shall be resurveyed, and the CAD drawing shall be drawn.

Source: The copyright of Zhulong Forum belongs to the original author.

The first level of excavation shall be protected immediately.

During excavation, pay attention to the protection of underground pipelines, cables, cultural relics and other structures not shown in the drawings.

Design elevation of subgrade: the crown cross slope is 2.0%, and the rotation axis and design elevation are located at the edge of the central separation strip.

It is strictly prohibited to go beyond the excavation level.

The waste soil after the surface cleaning shall not be dumped randomly.

5) Before the subgrade excavation, the surface shall be cleaned.

For rock that cannot be excavated directly by machinery or manual work, the blasting method shall be used for excavation.

The subgrade earthwork construction is not only to face the problem of large construction volume, but also to know how to deal with and deal with its complex and changeable construction conditions, Let’s take a look at the key points of construction in the common subgrade earthwork.

At the junction of the cutting and the embankment, the side ditch shall be gently led to the natural ditch or drainage ditch on both sides of the embankment, so as not to cause ponding near the embankment or erode the embankment.

The width of the falling platform shall be 2m, and the inward 3% transverse slope shall be set.

2.

Bench excavation shall be carried out according to the design platform elevation to facilitate the control of bench position.

Whether in railway engineering or highway engineering construction, the subgrade earthwork is a very basic and important construction step.

Construction preparation 1.

The size of the platform intercepting ditch shall be constructed according to the design requirements.

The topsoil, arable soil, and unsuitable soil must be stacked in a centralized manner according to the location specified in the drawing, so as to prepare for the later central separation zone, excavation side ditch backfilling, and slope greening.

For integral subgrade, superelevation rotates around the outer edge of the central separation strip; For separated subgrade, the superelevation rotation axis is 1.0m away from the outer edge (forward direction) of the left soil shoulder, that is, whether it is integral or separate subgrade, the superelevation rotation axis remains unchanged relative to the center of the traffic lane, but the soil shoulder maintains a normal slope and tilts outward.

The surface cleaning thickness of dry land is 20cm, and the surface cleaning thickness of mountainous areas is 10cm.

3) The berm and debris fall platform shall be set according to the design requirements, with neat and beautiful appearance to prevent water and soil loss.

Before the commencement of site preparation (geotechnical test), the filling materials along the project and in the borrow area shall be sampled and tested every 5000 cubic meters or when the soil quality changes according to the method specified in the Code for Highway Geotechnical Test, to determine the type, grade, liquid-plastic limit, natural density and other detailed data of the filling materials, and to determine the maximum dry density and optimum moisture content of the soil by the heavy compaction method.

The drainage of intercepting and drainage ditches shall not harm the subgrade.

Provide basis for filling selection and compaction process.

Once the above conditions are found during excavation, report immediately and protect the site.

For soft rock and strongly differentiated rock, those that can be directly excavated by machinery shall be excavated by machinery or manually.

4) When excavating the fill area below the original surface, such as the pond, except for suitable materials, the excavation depth shall be determined according to the actual soil conditions to ensure the bearing capacity of the base.

Temporary drainage facilities shall be built during earthwork construction.

The excavation slope shall be repaired from the excavation surface to the bottom in sections, and the slope of the newly excavated slope shall be brushed every 2~3m, and the dangerous rocks and loose rocks shall be removed at the same time.

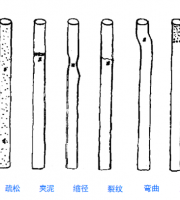

Schematic diagram of earth-rock excavation: intercepting ditch shall be completed before cutting excavation, and anti-seepage work shall be done according to soil conditions.

Layout of subgrade pile points 3.