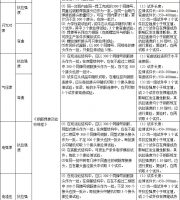

The common hidden dangers in the construction power supply are that the incoming line of the power supply is not standardized, the power lighting mixed switch box is small from the ground, and sundries are stored.

According to the above hazard source analysis, we are prone to the following safety accidents during winter construction: fire, electric shock, falling from height.

It is forbidden to hang wires and dry clothes on wires.

2.

In case of heavy wind, snow and rain, it is necessary to carefully check the temporary electric equipment on the site, check whether the circuit and electric box are safe and reliable, and immediately stop the construction in case of any hidden danger to ensure the safe use of electricity.

The electric tools shall be tested and qualified by professional electricians, and shall not be used when the tool shell and handle are broken, the power cord is damaged, and the plug is damaged.

5.

Special grounding line shall be set during electric welding operation.

There was a minibus above the trench.

The winter time of Shehong is generally from December to February of the next year.

The welding operation is carried out under the tight grip of the operator.

When using electric tools, check whether the power supply has leakage protector.

4.

Therefore, great attention must be paid to fire safety in winter.

The safe electric welding operation is the most common high-risk operation.

People are prone to fire and electric shock accidents when using electric heating.

Affected by severe weather such as fog, snow, etc., it is easy to cause power line disconnection, short circuit, etc., resulting in electric shock.

The metal frame of the minibus head had been deformed.

.

Preventive measures 1.

Strengthen the implementation of organizational measures, and operators should strictly wear and use labor protection articles 4.

In dry winter, the material stacking area is prone to fire due to negligence.

2.

9.

Strengthen the regular inspection of equipment, and timely deal with the accident case on May 25, 2009 at 13:00, Li Yuanlong fell to the ground when he was repairing the minibus in the trench of an automobile repair company in Chaoyang District, Beijing, and died after being rescued.

Fire protection management at the construction site The construction site shall clearly divide the hot work, flammable material stacking, and the warehouse construction site shall be equipped with sufficient fire protection equipment to ensure that the fire protection equipment is complete and effective.

Once the welding operator gets an electric shock, it is difficult to get rid of the charged body due to muscle contraction, which is easy to cause serious consequences.

During the electric welding operation, because the electric welding machine uses high voltage current, it is easy to cause the risk of electric shock, Safety education shall be carried out for operators, safety measures shall be implemented before operation, equipment inspection shall be carried out, and strong supervision shall be carried out during operation to avoid accidents.

We focus on the winter safety knowledge from the specific requirements of “fire prevention, rain and snow prevention, frost prevention, anti-skid, and anti-theft”.

1.

It is strictly forbidden to pull and connect wires without permission.

The electrical equipment used at the construction site must be used in strict accordance with the system of “one machine, one switch, one box, one leakage”, and the door of the electrical box should be locked at any time.

The electricity consumption in winter is more than usual.

Once the exposed part of the tool is electrified, a large current will pass through the human body, which is easy to cause serious consequences.

3.

Winter is the peak period of mechanical injury and vehicle injury.

Flammables entering the warehouse should be stored by category, and warning signs and fire extinguishers should be hung.

Fire control management of material warehouse.

The temperature drops in winter, and the temperature in many areas is below 0 ° C (negative temperature).

The storage and use of flammable and explosive substances shall be managed by specially-assigned persons, and fire prevention measures shall be taken.

Smoking and hot work are prohibited near the storage area of flammable and explosive materials.

Its power line is easy to leak due to stretching and friction.

The electric welding machine is directly placed on the reinforcement.

It is strictly prohibited to weld in rainy days and especially humid environments 3.

In addition, the bad weather will also have a certain impact on the power line.

The safe voltage of 12V shall be used in all wet places.

5.

Contents: winter construction hazard source analysis winter safety common sense winter construction safety management winter construction hazard source analysis 1.

winter construction hazard source analysis 1.

The main reason for electric shock in welding operation is 1.

Therefore, the safety of electricity consumption in winter construction must be kept in mind.

2.

Strengthen the safety training and education of welders, and implement the safety responsibility system 2.

The welding tool has great mobility.

7.

It is forbidden to use bare wires and broken cables.

The installation of wires, lamp sockets and electrical equipment must be carried out by professional electricians.

Obvious signs shall be set at the place where fire-fighting equipment is stored, and all fire-fighting equipment shall not be arbitrarily used.

4.

2.

The connection of the power line is easy to fall off and make the metal shell live, resulting in electric shock accidents; Or the metal shell is electrified due to moving damage under adverse conditions, resulting in electric shock accident.

In the low temperature season (the daily average temperature is lower than 5 ℃ or the minimum temperature is lower than – 3 ℃), antifreezing and warming measures shall be taken.

The resistance between the person and the tool is small.

The distance between acetylene and oxygen cylinder shall not be less than 5m and shall not be inverted.

3.

Fire safety in winter 1.

Before winter, all mechanical equipment and cables on the construction site shall be comprehensively inspected and maintained, and mechanical and electrical faults shall be eliminated immediately.

6.

In addition, the road is wet and slippery.

is frozen, and the material is easy to crack, which brings many difficulties.

Due to the low temperature in winter, the constant temperature process of personnel in heating and production is easy to produce many safety hazards, and the dry climate in winter is easy to cause fire.

One switch and multiple machines exit from the door of the box, and the electric welding machine is easily clipped and broken.

3.

The moisture contained in soil, concrete, mortar, etc.

At the time of the accident, the site was located in the trench of the garage.

The low temperature causes certain changes in the performance of vehicles and machinery.

Electric shock accident is one of the most common accidents in construction, which is often caused by human negligence and illegal operation.

winter temperature is low, affected by cold air, the construction work surface and road are easy to freeze and slide, in addition to the heavy clothes of people in winter, the movement becomes relatively slow, and fall accidents are easy to occur when working at heights.

The process of construction in winter is called winter construction.

3.