Causes of sagging (sagging, flowing, etc.) of wall coating during construction: ① low viscosity of coating; ② The coating is too thick; ③ The coating itself has sagging quality problems; ④ During spraying, the distance between the spray gun and the wall is too close, or the coating is not evenly mixed, and the upper coating is too thin.

If necessary, the residue should be removed before reuse.

Double Head Lifting Pin Anchor

Note that the paint with good quality should be selected first.

The paint contains too much heavy pigment, and some of the paint is sagging; 4.

5.

The causes of peeling and peeling of the coating film during the construction of wall coating are: ① low bonding strength of putty; ② The moisture content of the base course is too high; ③ Apply paint before the putty is completely dry.

The reasons for the discoloration or discoloration of the wall coating in a short period of time after coating during the construction are: ① poor light resistance, alkali resistance, or no resistance to powdering of the pigments used in the coating; ② Poor weather resistance of base material; ③ The aging resistance of coating is unqualified.

Reasons for uneven gloss of wall coating during construction: ① improper selection of diluent when diluting paint; ② The film thickness is uneven during construction; ③ The number of coating passes is not enough.

Painting shall be carried out according to the process procedure: first vertically, horizontally and diagonally, and then vertically level the coating to make the coating film thickness uniform.

Solution: ① Select the coating with covering power (contrast ratio) meeting the requirements of quality standards; ② The viscosity of the coating is required to be qualified; ③ The coating with precipitation or layering shall be fully stirred before coating; ④ Adjust the color of the primer or putty to be as consistent as possible, or apply one more coat of surface paint.

Next, pay attention to clean the surface of the object to keep it flat, smooth and dry.

6.

We should select high-quality paint and thinner with appropriate volatilization rate, and control its penetration.

3.

The main reasons are too much pigment or too coarse particles in the paint; The paint itself is not clean, mixed with sundries, and used without screening; The ambient temperature is low when the paint is mixed, and the bubbles in the paint are not completely dispersed and discharged; The surface of the object is not cleaned, and there are sundries such as sand particles, which are mixed into the paint film during painting; The containers used (brushes, paint buckets, spray guns, etc.) are not clean, and there are residual impurities brought into the paint; The cleaning and protection of the construction environment are not enough.

The construction environment temperature is too low, and the paint film dries slowly; 3.

Solution: ① Select diluent according to regulations; ② Pay attention to uniform coating during construction; ③ Paint to a sufficient number of coats, and increase the number of coats if necessary.

Source: The article is transferred from the internet, and we respect the originality,

.

Finally, it must be noted that it is not allowed to reuse the appliance containing different types and different performance paints.

The construction ambient temperature shall meet the standard requirements of the coating type.

Solution: ① Properly add anti-floating color and anti-blooming additives in the paint, and fully mix them evenly; ② Select suitable pigments with good quality when producing paint, and make them disperse well in the paint to improve the viscosity of the paint; ③ The coating shall be uniform to make the film thickness consistent; ④ The base course can be well treated, and the primer can be sealed.

5.

The reasons for the poor covering power of the coating film during the construction of the wall coating: ① the poor covering power of the coating itself; ② Low viscosity of coating; ③ The coating with precipitation and layering is not fully stirred before coating; ④ The color difference between the primer or putty layer and the top coating is large.

The reasons for the blossoming of the coating film during the construction of the wall coating: ① the coating itself has floating color; ② Poor dispersion of pigment in paint; ③ Uneven thickness of coating film; ④ The surface roughness of the base course is different, or the base course is too alkaline; ⑤ At the junction of different colors, the paint colors penetrate each other.

Then it is very important to reasonably arrange the construction sequence of each type of work to ensure that the construction environment of painting is free of sundries and dust.

During the coating construction, wall coatings often have some problems such as sagging, poor covering power and uneven gloss.

Before use, it must be finely screened, mixed evenly, and used without bubbles.

The surface of the object shall be smooth and clean, and the surface oil, water and other dirt shall be removed.

How are these problems caused? How should we solve it? 1.

Solution: ① choose polymer cement putty or acrylic lotion putty with high bonding strength and good water resistance; ② Make the base layer meet the requirements of coating conditions; ③ Apply paint after the putty layer is dry.

Solution: ① The pigment with good light resistance, alkali resistance and powdering resistance shall be selected during coating production; ② The base material and pigment with good weather resistance shall be selected during coating; ③ Select the coating that has passed the aging resistance test.

Oil, water and other dirt on the surface of the object base are incompatible with the paint, affecting the adhesion and causing the paint film to sag; Solution: 1.

Solution: ① It is required that the viscosity of the coating is qualified, the proportion of pigment and filler is appropriate, and it must be stirred evenly before application; ② Each layer of paint shall not be too thick, and the amount of paint dipped by construction tools (brushes or rollers) shall not be too much; ③ Negotiate with the manufacturer to solve the sagging problem; ④ Adjust the distance between the spray gun and the wall, and mix the paint evenly before application.

There are dust, sand and other sundries sticking to the brush or falling on the paint film.

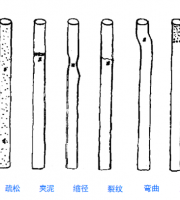

The surface roughness of the coating film is specifically manifested as the uneven surface after the coating film is formed, with sand-like bulges or small bubbles.

The surface of the base layer of the object is uneven, the thickness of the paint film is uneven, the drying speed is different, and the parts with too thick paint film are easy to fall; 5.

The moisture content of the base course shall not be greater than 8%, and the pH value shall not be greater than 10; ⑤ When applying paint repeatedly, first apply the paint that is not easy to bleed, then apply the paint that is easy to bleed, and then apply the paint after it is completely dry.

2.

The coating or painting is too thick, and the paint film is too heavy and sagging; 2.

7.

The spray gun shall be sprayed vertically, circumferentially, and then horizontally according to the specified process procedure, so that the paint film is formed evenly and the thickness is consistent.

3.

4.

2.

8.

The moving speed of the spray gun and the distance from the object shall be controlled evenly during painting.

4.

The main reasons for dropping, sagging and uneven paint film on the surface of the base layer are as follows: 1.