– plastering surface mortar – maintenance.

Construction process.

Watering for wetting and slurry roughening: water the wall first, and then slurry roughening.

Base layer cleaning: Before plastering construction, the surface of external components should be treated, and the holes should be blocked, including screw holes, equipment pipeline slots, and holes.

Then, start dividing strips.

When sticking, use plain cement paste to plaster both sides into a 45 ° splay shape.

2.

Curing: After plastering is completed at room temperature for 24 hours, it shall be cured by spraying water for at least 7 days; Thermal insulation measures shall be taken for winter construction.

The outdoor cement mortar plastering process is the same as that of the interior wall, except that when selecting mortar, cement mortar or special dry mixed mortar should be selected.

9.

Before plastering, a plan should be prepared and a sample room should be prepared, After the acceptance of the sample room, large-scale construction can be carried out.

After the initial setting of the surface, it is watered for curing.

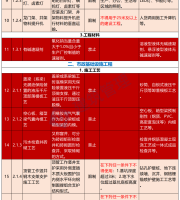

Exterior wall: base layer cleaning Watering and wetting – Blocking door and window joints, scaffolding holes, and holes – Hanging vertical, square, leveling, plastering cakes, and reinforcing bars – Plastering bottom and middle layers – Embedding partition strips, plastering surface plaster – Plastering drip lines, and erecting partition strips – Maintenance 1.

Corner protection and cement windowsill plastering: use 1:2 cement mortar as corner protection, with a height of not less than 2m and a width of not less than 5cm on each side.

It should be leveled and straightened with a large bar, and roughened with a wooden trowel.

The vertical bar should be adhered to the same side of the snapped vertical line to prevent uneven division.

Hang vertically, square, align, and plaster the cake: The cake is made of 1:3 cement mortar to 5cm square, with a spacing of about 1.5m, and arranged in a plum blossom shape.

Plastering cement skirting (120 high): fill the reinforcement with the plastered cement cake, and apply a layer of plain cement slurry (mixed with construction adhesive); Use 8mm thick 1:3 cement mortar for priming; Then use a layer of plain cement slurry to fluff (mixed with construction adhesive); 6mm thick 1:2.5 cement mortar plastering, compaction and polishing.

The main structure has passed the acceptance of relevant units.

The plastering base has passed the acceptance process.

3) Snap lines for dividing and embed dividing strips: For large area plastering, snap dividing lines and stick dividing strips according to the drawing requirements.

Tool preparation: mortar mixer, trolley, flat shovel, iron trowel, wood trowel, internal and external corner trowel, ash spoon, large bar, middle bar, 2m guiding rule plate, plumb bob, box ruler, square ruler, ash support plate, etc.

7.

2) Plastering bottom layer and middle layer of mortar: According to different substrates, a layer of adhesive cement slurry can be brushed before plastering bottom layer of mortar, and then 1:3 cement mortar (1:6 cement mortar should be plastered on the bottom layer of aerated concrete wall).

During each measurement, one end of the guiding rule should extend to the top or root of the wall, and it should be synchronized with the flatness detection of the wall.

.

5.

4) Plastering the surface layer mortar and setting up the dividing strip: When the bottom mortar is 70% dry, start plastering the surface layer mortar.

The cover plaster is finished twice, with a thickness of about 2mm each time.

First, scrape a thin layer of plain cement paste, and then plaster the surface mortar to level with the dividing strip.

The dividing strips should be made of Korean pine and soaked thoroughly with water before adhesion.

2.

Bottom plastering: The thickness of each layer of bottom mortar is 5-7mm, and it should be leveled with the filled reinforcement in layers.

3.

Technical preparation 1.

The layered plastering and reinforcement filling shall be leveled and straightened with a wooden rod at ordinary times, and the wood float shall be used for roughening.

When plastering each layer, the plastering cake is used as the reference for reinforcing to ensure horizontal and vertical alignment.

8.

1、 Construction preparation 1.

Wall reinforcement filling: When the mortar cake reaches 70% dry, use the same mortar as the plastering layer to fill the reinforcement.

2.

When the wall height is greater than 3.5m, it is advisable to make transverse reinforcement.

6.

Then, the plastering cake is operated according to the plastering operation.

When there is no open water on the surface, dip a soft bristle brush in water and lightly brush it in the same direction perpendicular to the ground to ensure that the color of the surface layer is consistent.

The width of the standard reinforcement is 50mm, and the spacing between the two reinforcements is 1.5m.

The following items should also be noted during construction: 1) For high-rise buildings, use the large corners of the wall, both sides of the door and window, and use a theodolite to make a straight line to find the vertical; The multi-storey building is suspended vertically from the top floor using a large plumb line, and the iron wire is used to align.

Wall verticality: acceptable standard: [0,4] mm; Use a 2m guiding rule to measure the perpendicularity of the wall.

After the ash layer is dry, use plain cement paste to hook the joints.

The slurry casting amount shall not be less than 80% of the wall area.

Plastering the cover plaster: Start plastering the cover plaster when the bottom plaster is sixty to seventy percent dry.

5) Wiping water drip lines: When plastering cornices, window sills, window lintels, balconies, awnings, coping, and waist lines protruding from the wall, as well as decorative convex lines, the upper surface should be made into an outward flow slope, and reverse slopes are strictly prohibited.

3、 Quality standard and acceptance 1.

The plastering layer on the window sill should be deep into the cut in the lower sill of the window frame, and be tightly blocked.

1.

The finishing plaster shall be compacted and polished with an iron trowel.

4.

Material preparation: Ordinary Portland cement: The cement shall be of the same manufacturer, brand, and strength grade, and shall pass the site retest; Medium sand: with a particle size of 0.35-0.5, pass through a 5mm aperture sieve before use; Alkali resistant mesh cloth or steel wire mesh, lime powder, etc.

The water flow gradient and drip line groove should be no less than 40mm from the outer surface, and the depth and width of the drip line should be no less than 10mm.

The burrs shall be mechanically or broomed, with firm adhesion and uniform density.

Use a wooden bar to level it horizontally and vertically, rub it with a wooden trowel, and smooth and compact it with an iron trowel.

Interior wall: base layer cleaning – watering and wetting – hanging vertical, square, leveling, plastering cake – plastering cement skirting or dado – doing corner protection and plastering cement windowsill – wall reinforcement filling – plastering bottom mortar – repairing reserved holes, electrical box slots, boxes, etc.

The 1:1 cement mortar mixed with 8% construction adhesive shall be used for slurry casting and roughening, with suitable consistency.

The thickness of each layer should be controlled within 5~7mm.

After slurry casting and roughening, water shall be sprayed for curing for at least 2 days.

The horizontal horizontal line can be controlled in circles based on the floor elevation or the construction+500mm line as the horizontal reference line.

2.

Use an external corner trowel to make a right angle; The window sill is paved with 1:2:3 pea stone concrete, and a day later, a 1:2.5 cement mortar surface layer is applied.

Water the bottom mortar wall evenly and wet it.

3.

Drip lines and grooves should be made below.

3.

2.