4) After rolling a layer with a flat roller, the surface shall be roughened manually or with a bulldozer.

The thickness of the filled soil (plain soil, lime soil, and gravel soil) should not exceed 25-750px.

When the soil has an appropriate water content, water plays a lubricating role, reducing the frictional resistance between soil particles, and making it easy to compact.

.

When rolling in sandy soil, the soil particles will move in all directions due to the large unit pressure of sheep foot, causing damage to the soil structure.

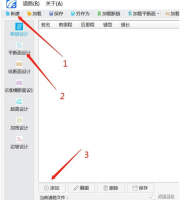

1.2 Mechanical compaction method 1) In order to ensure the uniformity and compactness of the filling compaction, avoid the sinking of the roller, and improve the rolling efficiency, it is advisable to use a light bulldozer to flatten before rolling with the rolling machine, and preload at a low speed for 4-5 times to make the plane flat and compact; When using a vibratory flat roller to compact crushed stone soil, static pressure shall be applied first, and then vibration compaction shall be carried out.

Where the edges, corners, and slope edges cannot be compacted, manual compaction or small compaction machines shall be used to coordinate the compaction.

Due to the construction site, construction machinery, special construction technical requirements, and other reasons, the backfill construction method generally adopts manual compaction method or mechanical compaction method.

Therefore, in actual construction, do not blindly increase the number of compaction passes too much.

Under normal conditions, the vibratory compaction method has a better compaction effect on sandy soil.

When it approaches the maximum dry density of the soil, although the compaction work increases significantly, the dry density of the soil hardly changes.

If the surface of the soil layer is too dry, it shall be watered and then backfilled to ensure a good bonding between the upper and lower layers.

Mechanical backfilling and compaction can only be used without damaging the pipeline.

The dry density of compacted fill has a certain relationship with the work exerted on it by the compaction machinery.

With the rapid economic growth, there are more and more large span structures, high-rise buildings, and super high-rise buildings.

2) When compacting the fill with rolling machinery, the driving speed should be controlled.

1.

Improving design standards and increasing structural loads have increasingly high requirements for foundation stability, and the construction quality and construction technology of backfill soil are also receiving increasing attention.

1.1 Manual compaction method 1) Manual compaction method shall be adopted for places where mechanical compaction cannot be achieved and small areas of backfill.

2.3 Vibration compaction method: The vibration compaction method is to place a vibration compactor on the surface of the soil layer.

3.1 Impact of compaction work The impact of compaction function (referring to the weight of compaction tools, rolling times or hammer height, action time, etc.) on the compaction effect.

3) The method of “thin filling, slow driving, and multiple times” should be used for filling and compaction with a flat roller.

3) Manual tamping shall be used in places where the tamping machine cannot work, and the virtual paving thickness shall not be greater than 500px.

The rolling direction should gradually be from both sides to the middle.

Factors that affect the compaction of fill The compaction quality of fill is related to many factors, among which the main influencing factors are: compaction work, soil moisture content, and the thickness of each layer of soil.

Before manual tamping, the fill shall be preliminarily leveled.

Please pay attention to the Housing and Leisure Nanbo Club and click on it after reading.

Sheep foot rollers are generally used for rolling cohesive soil and are not suitable for sandy soil.

4) When backfilling the pipe trench, the soil around the pipe shall be filled and compacted manually, and the backfilling shall be carried out simultaneously from both sides of the pipe until the pipe top is more than 0.5m.

Rolling machines include flat rollers and sheep foot rollers.

The width of each overlap of the roller should be about 375px-625px to avoid missing compaction.

The pressure per unit area of a sheep foot roller is relatively large, and the soil compaction effect is good.

The tamping shall be carried out in a certain direction, with one tamping and half tamping, and the tamping shall be connected in rows, with two vertical and horizontal intersections, and layered tamping.

Flat roller (smooth roller) is a self-propelled roller powered by an internal combustion engine, with a weight of 6-15t.

Dry soil is not easy to compact due to the high frictional resistance between soil particles.

The compaction method is suitable for deep reinforcement of cohesive soil, collapsible loess, and gravel filled foundations.

Unless otherwise specified, the compaction degree shall generally be such that the wheel settlement does not exceed 25px-50px.

The compaction machinery should maintain a certain distance from the foundation pipe to prevent crushing or displacement of the foundation and pipe.

Under the action of compaction vibration, the soil particles undergo relative displacement and reach a compact state.

When tamping the foundation trench and floor, the tamping route should start from the four sides, and then tamp towards the middle.

3.

Generally, the horizontal roller and vibrating roller should not exceed 2 km/h, and the number of compaction passes should be controlled.

Before tamping, the fill should be initially leveled, and the rammer should tamp it in turn, evenly distributed, without leaving gaps.

2.2 Compaction method Compaction method uses the free falling impact of the hammer to compact the soil, compressing the pores in the soil and arranging the soil particles more closely.

Generally, the thickness of the fill should not be greater than 625px, and the number of compaction times for each layer should be 3-4.

2.

When compacting the fill with rolling machinery, the driving speed should not be too fast, and generally the flat rolling should not exceed 2kmPh; The roller should not exceed 3kmPh.

The number of compaction times for each layer should be 6-8 times.

Thank you for your forwarding and sharing! On the basis of expounding the construction methods of backfill, this paper summarizes the specific methods of backfill compaction, analyzes the factors that affect the compaction of backfill, and finally analyzes the common problems and treatment measures of earthwork backfill.

2.1 Rolling method The rolling method uses the pressure of mechanical rollers to compact the soil to achieve the required compactness.

During operation, the distance between the grinding wheel edge and the filling edge should be greater than 500mm to prevent slope sliding and chamfering.

A large number of experiments and engineering practices have proven that after compaction of the soil foundation, the plastic deformation, permeability coefficient, capillary water action, and temperature insulation performance of the roadbed have been significantly improved.

The compaction methods for filling soil include rolling compaction, compaction, and vibration compaction.

In the ramming type, in addition to manually used stone and wood rammers, mechanical equipment includes rammers, ramming plates, pneumatic rammers, and frog rammers.

For loose soil compaction, it is advisable to first use light roller compaction, and then use heavy roller compaction to achieve better results.

At the beginning of compaction, the dry density of the soil increases sharply.

3.2 Impact of Water Content Under the same compaction work condition, the water content of the fill has a direct impact on the compaction quality.

2) Use small machines such as a frog rammer to tamp the soil in real time.