The general action radius should not be greater than 3m.

Especially during the pouring process, it should be checked at any time whether it is carried out in accordance with the process regulations.

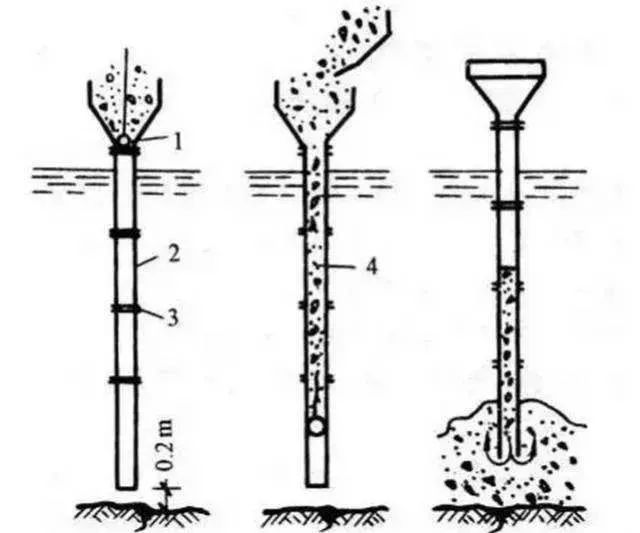

When the water depth is deep, the vertical pipe method can be used for pouring.

The problem arises.

Generally, the mix ratio is the same as that of onshore concrete, but due to the impact of water, it is generally one lower strength grade than onshore concrete under the same conditions, so a strength grade should be increased.

4.

Since the concrete cannot be added with water at will, what should be done with underwater concrete? Don’t worry, today we will take a look at the pouring method of underwater concrete.

An automatic opening and closing valve should be installed at the bottom, and a funnel should be installed at the top.

The grouting pressure is related to the consistency of the grouting fluid, the average particle size of the pre filled aggregate, and the required diffusion radius.

After formwork removal, visual inspection should also be conducted, and if necessary, core drilling inspection and water pressure test should also be conducted.

.

5.

Using this method, the pouring time should be minimized, and the first poured concrete should not solidify until the pouring work is completed.

Underwater concrete pouring is a hidden construction process that cannot be visualized, and quality inspection must be strengthened to ensure project quality.

When pouring underwater concrete with a strength grade not lower than C25, it is strictly prohibited to add water to the concrete truck at will.

When the water depth is shallow, the pouring method can be used for construction.

It is connected with a rubber padded flange.

2.

The number and location of conduits should be determined based on the pouring range and the action radius of the conduits.

Folding bag masonry method: The underwater concrete is poured using the bag masonry method, which involves placing the concrete half full into a solid sack or cloth bag, and the diver performs the masonry and pouring underwater.

With a water tank surface, the slurry discharge pressure at the bottom of the pipe should be added to the water pressure caused by the corresponding water depth.

With this pouring method, the layer between the bags can be cemented by the cement slurry squeezed from the bag holes, but its integrity is ultimately very poor.

1.

Folding flexible bottom hanging box method The flexible bottom hanging box method is to place concrete in a closed hanging box that can be opened at the bottom, directly reach the pouring site through the water layer, and then open a 0.3~0.4m bottom for unloading.

The diameter of the conduit is 25~30cm, and each section is 1~2m long.

If the average particle size of the pre filled aggregate is within 150mm and the diffusion radius is within 1.5m, when the water depth is zero, the slurry discharge pressure at the pipe bottom is about 50-150kPa.

Folding pouring method Pouring method can be used to pour underwater concrete, which can be used when the water depth on the shore does not exceed 1.5m.

In addition, there is also a method of accelerating coagulation agent, which is relatively reliable, but the cost is relatively high.

The slump of concrete should be 7~10cm.

6.

The folded conduit method uses the conduit method to pour underwater concrete, which is applicable to situations where the water depth does not exceed 15 to 25m.

The newly poured concrete pile is squeezed into the poured concrete body by means of tamping or vibration, so that only the front concrete slope is in direct contact with water.

The pores of the bag should allow mortar to seep out but should not be too large.

Folded pre filled aggregate grouting method The underwater pre filled aggregate grouting method requires that the cement mortar have a certain fluidity and certain anti segregation ability.

The concrete bags should be staggered and placed close to each other.

Folding flexible pipe method The flexible pipe method uses flexible hoses to transport concrete, and uses the pressure of surrounding water on the hoses to control the falling speed of concrete.

If it is required to reach C25, it should be mixed to C30.

The slump of such concrete should be 5~7cm, and dry mixed concrete should not be used.

The reason is to ensure that the concrete mix ratio does not become disordered due to the addition of water.