During the mixing and pouring process of concrete, the following contents should be checked: ⑴ Slump inspection should be conducted at the pouring location, and the slump inspection should be conducted at least twice per work shift.

Under no circumstances shall water be added to the concrete mixture to increase its slump The strength inspection is used to check the strength of concrete in structural components.

Quality control of concrete transportation and pouring (1) During concrete transportation, it is necessary to ensure that the concrete does not segregate, layer or change in composition, and ensure smooth unloading and transportation.

Note: 1) When the average temperature of the day is below 5 ℃, watering is not allowed; 2) When using other types of cement, the curing time of concrete should be determined based on the technical performance of the cement used; 3) When it is inconvenient to water the concrete surface or use plastic cloth, it is advisable to apply curing agent; 4) For the maintenance of large volume concrete, temperature control measures should be taken according to the construction technology plan according to climatic conditions.

5) The wall can be left within 1/3 of the span of the lintel at the door opening, or at the junction of the vertical and horizontal walls.

After the completion of concrete pouring, effective curing measures should be taken in a timely manner according to the construction technology plan, and the following regulations should be met: ⑴ The concrete should be covered and moisturized for curing within 12 hours after pouring; ⑵ The time for concrete watering and curing: for concrete mixed with Portland cement, ordinary Portland cement, or slag Portland cement, it shall not be less than 7 days; For concrete mixed with retarding admixtures or with impermeability requirements, it shall not be less than 14 days; ⑶ The watering frequency should be able to maintain the concrete in a moist state; The water used for concrete curing should be the same as the water used for mixing Concrete that is cured by covering it with plastic cloth should have all exposed surfaces tightly covered and there should be condensation water inside the plastic cloth Before the concrete strength reaches 1.2N/neneneba mm2, it is not allowed to step on it or install formwork and supports.

When pouring the upper layer of concrete after the initial setting of the bottom layer of concrete, it should be treated according to the requirements for construction joints in the construction technical plan When using a vibrator to compact concrete, the vibration time at each vibration point should be such that the concrete surface shows laitance and no longer sinks When pouring beams and slabs that are integrated with columns and walls, the pouring should be stopped for 1-1.5 hours after the completion of column and wall pouring before continuing; Concrete should be poured simultaneously for beams and slabs; For beams with a height greater than 1m, concrete can be poured separately The pouring of large volume concrete should be carried out in reasonable sections and layers, so that the concrete rises evenly along the height; Pouring should be carried out when the outdoor air temperature is low, and the pouring temperature of concrete should not exceed 28 ℃.

The measurement of concrete raw materials and the quality control of concrete mixing.

1.

The temperature of concrete pouring refers to the temperature at a depth of 50-100mm after concrete vibration The position of construction joints should be determined according to the design requirements and construction technical plan before concrete pouring.

3) A one-way board, left at any position parallel to the short edge of the board.

The specimens should be randomly selected at the pouring location of the concrete.

Concrete pouring can only be carried out after meeting the requirements; Clean up the debris inside the template and oil stains on the steel bars, block the gaps and holes in the template tightly, and wet them with water; When pouring concrete on the foundation or foundation, silt and debris should be removed, and drainage and waterproofing measures should be taken; In dry non viscous conditions, water should be used for wetting The free height for concrete to fall from a height should not exceed 2m.

2.

When continuing to pour concrete at the construction joint, the following regulations should be met: 1) The compressive strength of the poured concrete should not be less than 1.2N/m2; 2) On the hardened concrete joint surface, the cement film, loose stones, and weak concrete layer should be removed, and it must be fully wetted and washed clean, without water accumulation; 3) Before pouring concrete, lay a layer of cement mortar with a thickness of 10-15mm and the same composition as the concrete; 4) The newly poured concrete should be carefully compacted to ensure a close bond between the old and new concrete.

3.

4) Floors with primary and secondary beams should be poured along the direction of the secondary beam, and construction joints should be left within the middle one-third of the span of the secondary beam.

During the concrete pouring process, supervision personnel should check the raw material measurement and mixing time of the production plant from time to time, and keep inspection records in a timely manner.

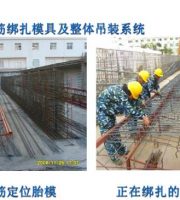

(2) Before concrete pouring, the quality, quantity and position of formwork, support, reinforcement and embedded parts shall be checked and accepted one by one, and acceptance records shall be made in time.

Construction joints should be left in areas where the structural stress is relatively small and convenient for construction.

6) For complex structures such as two-way load-bearing floors and large volume concrete structures, the position of construction joints should be reserved according to design requirements The treatment of construction joints should be carried out according to the construction technical plan.

The concrete of the same construction section should be poured continuously, and the previous layer of concrete should be poured before the initial setting of the bottom layer of concrete.

1) Columns should be left on the top surface of the foundation and below the beams.

This project uses pre mixed commercial concrete, and its production process (including raw material measurement and concrete mixing) is relatively stable.

When the pouring height exceeds 3m, a string tube or vibrating chute should be used to make the concrete fall The entire time of concrete transportation, pouring, and intermission should not exceed the initial setting time of the concrete.

The quality control of concrete construction includes the measurement of concrete raw materials, the inspection and acceptance control of the mixing, transportation, pouring, and maintenance processes of concrete mixtures.

Concrete quality inspection: The strength grade of structural concrete must meet the design requirements.

2) A large cross-section beam connected to the board as a whole is left at a distance of 20-30mm below the bottom surface of the board.

1) The size of concrete test blocks used for testing and evaluating concrete strength is mainly 150x150x150mm cubic test blocks, made using standard molding methods and standard curing conditions.

.

4.