2.

3.

There are problems with the excavation and grouting pile: standardized construction requirements: there should be sufficient lighting, ventilation, and exhaust facilities inside the excavation and grouting pile hole, and there should be escape safety ladders.

The cushion blocks for the protective layer of the reinforcement cage should be circular cake shaped, with a longitudinal spacing of no more than 2 meters.

b.

After placement, the reinforcement cage should be prevented from sinking or floating.

When the diameter of the steel bar is greater than or equal to 25mm, mechanical connection should be used, and after the wire head inspection is qualified, a protective sheath should be added.

(2) Standardized requirements for bridge pier and abutment construction: 1.

③ Common problems with mud pits: Standardized construction requirements: After cleaning the hole, the mud indicators should be sampled from the average values of the top, middle, and bottom of the pile; The surrounding area should be enclosed.

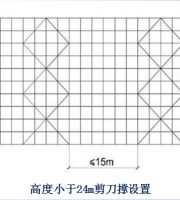

Standardized construction requirements: a.

The standardization of bridge construction technology mainly requires key requirements: firstly, to ensure the admission of formwork, and not allow unqualified formwork to be used in production to ensure the appearance quality of concrete; The second is to control the prefabrication process of beams and slabs, ensure the strength of concrete, the thickness of steel reinforcement protection layer, and ensure the thickness and flatness of the bridge deck pavement layer; The third is to do a good job in the “first article analysis system”.

Bridge Bored Pile Foundation ① Common Problems in Reinforcement Cage Manufacturing: The main reinforcement joint of the reinforcement cage is set incorrectly, with a diameter of 25mm, and should be mechanically connected with steel bars instead of double-sided welding; And no reinforcement protective layer cushion blocks were used.

The bearing capacity and geological conditions of the foundation should meet the design requirements, and geotechnical tests should be conducted.

Each layer should be symmetrically arranged along the circumference with no less than 4 blocks Common problems with steel reinforcement cage processing site: Standardized construction requirements: Steel reinforcement cage processing should be made on a hardened site with a cement pedestal.

before mass construction can proceed.

Bridge pier construction: ① The installation of formwork for piers and cover beams meets the allowable deviation, and a dedicated person should be assigned to command the lifting and lowering of the bucket.

2.

④ Common problems with placement of steel reinforcement cages: ⑤ Placement of steel reinforcement cages: The placement should be aligned with the hole position, stable, slow, and straight, to avoid collision with the hole wall.

2 After dismantling the formwork, the column should be immediately wrapped with plastic film and cured by drip irrigation at the top of the pier

.

Double Head Lifting Pin Anchor

Pier cages and twisting cages are strictly prohibited.

Common problems with expanding the foundation: Standard construction requirements: The foundation should be widened by 0.5 to 1 meter compared to the plane size of the foundation.

Standardization of Construction Process for Bridge Substructure (1) Standardization Requirements for Common Foundation Construction of Bridges 1.

Cover and set up fences and warning signs at the openings, with the openings 30cm above the ground.

The prepared steel reinforcement skeleton must be flat and padded, and standardized mold production should be used.

After each bridge starts construction, the first finished or semi-finished product, such as pile foundation, pier column, beam, etc., should be analyzed by the construction unit organized by the director’s office to form a formal report on the quality status, process details, etc.