The extension of the small crossbar of the frame serves as a wall connecting rod, with a diameter of 800 mm or 1050 mm (800 mm for cantilever scaffolding and 1050 mm for floor standing scaffolding), and the exposed hole of the wall connecting rod is ≥ 100 mm. On the wall connecting rod, an additional steel pipe is added to the inner and outer walls, and connected with fasteners. The two ends of the small crossbar are exposed with holes of ≥ 100mm each. Entering the decoration stage, finished product protection needs to be added to the walls..

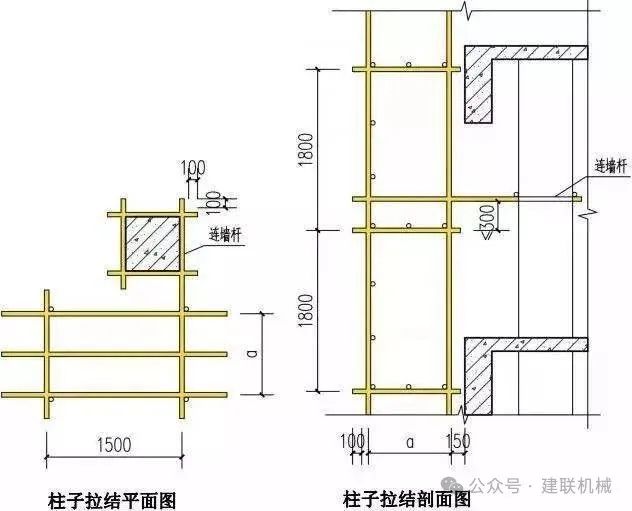

When it is not possible to set up connecting wall components in two steps and three spans at certain positions, column reinforcement measures should be taken. Attach a wall connecting rod to the frame, extending to one side of the column, and attach three small horizontal bars to the other three sides of the column. Connect them to the wall connecting rod with fasteners to form an embrace. The exposed length of the steel pipe is ≥ 100 mm..

1. This structure is used for situations where the column spacing of buildings is large, the floor height is ≥ 5 meters, and the setting of connecting wall components cannot meet the requirements of two steps and three spans..

2. When setting up the throwing brace, the throwing brace is fixed to the scaffold using a full length rod and rotating fasteners, with a tilt angle of 45 ° to 60 ° from the ground..

When starting to set up poles for ordinary scaffolding, a throwing brace should also be set up every six spans until the wall connecting rod is installed stably before it can be removed according to the situation..

When the floor height is too high and the column spacing is too large, lattice columns can be added. The cross-sectional size of the lattice columns should be 460 mm x 460 mm. The steel lattice is composed of four 150 mm x 150 mm x 12 mm angle steels and batten plates welded together. A steel pipe is set every two steps and three spans as a connecting wall component. When pouring the main concrete, embedded components for grid components should be installed..

The gap between the frame and the building should be less than 150 mm. When the gap is too large, the transverse horizontal rod at the wall end can be fully utilized to extend reasonably (should not exceed 40% of the frame width, and core filling rods should be added when it is greater than 400 mm). Protective measures such as laying steel fences and hanging safety nets should be taken on each floor to ensure that the gap between the frame and the building meets the requirements..

1. Steel fence: When the gap between the frame and the building is greater than 400mm, steel fence measures need to be used..

2. Safety net: When the gap between the frame and the building is 150-400 mm, safety net measures need to be used..

Embedding in shear walls Ф 60 mm PVC pipe, a is 800 mm or 1050 mm (800 mm for cantilever scaffolding and 1050 mm for floor standing scaffolding), connected to the frame by pulling a wall connecting rod through a pre embedded pipe..

Attach a steel pipe to each inner and outer wall on the wall connecting rod, and connect it with a fastener. The exposed length of the small crossbar is ≥ 100 mm..

1. There are two types of external wall components: embedded and through wall..

2. Before pouring concrete, embed the embedded parts into the shear wall or beam (or set bolt holes through the wall). One end of the rigid connector welding nut is inserted into the embedded parts (or through the wall bolt), and the other end is fixed to the scaffold pole through fasteners..

1. When erecting the soft cantilever, the soft cantilever uses the full-length rod and uses the rotary fastener to connect with the scaffold as the diagonal brace. The angle of inclination between the diagonal brace and the outer frame is 45 °~60 °. One diagonal brace is set every two spans. Two protections are set on the top of the diagonal brace to connect with the outer frame. The upper and lower parts are respectively dense safety net and horizontal net..