As the largest construction project in the history of water transportation in the hinterland of central Jiangxi so far, since the commencement of the project, the project management department of the comprehensive Wharf in the Hexi operation area of Zhangshu port area of Yichun port of Guangzhou Salvage Bureau has strengthened the standardization of on-site construction, refinement of project management and Project management informatization, further promote the treatment of common quality problems, carry out the construction of safe construction sites, comprehensively improve the quality and safety level of project construction, and make every effort to build the project into a “benchmark for the construction of inland ports and docks in Jiangxi”.

With standardized construction as the leader, “no rules, no square, with rules, the key is to implement”.

Now, in the front line of wharf construction, standardized construction measures are everywhere, and the details are within reach.

Each functional area is managed separately, and the labor operators become industrial workers, standardizing and programming each step of reinforcement processing.” Ji Huan, technical director of the project, said.

In order to further improve the project quality, the project management department organized and carried out the evaluation of the appearance quality of concrete structures, put forward measures to create excellence in concrete appearance, and promoted the improvement of the appearance quality of concrete structures.

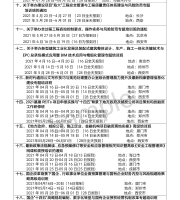

The project strictly implements the process of “scheme before implementation” to promote the construction.

In June 2021, the comprehensive Wharf in Hexi operation area of Zhangshu port area of Yichun port, which attracted much attention, officially started the journey of building a “quality project” with high standards.

In order to ensure the quality of the project, Guangzhou Salvage Bureau figured out the implementation plan for the establishment of quality project with more than 30000 words long before the formal commencement of the project, and comprehensively launched the standardization construction.

After the first project acceptance of each subdivisional project is excellent, in view of the defects and deficiencies in the process method, process flow, key points of quality control, safety protection demonstration and on-site civilized construction, further improve the first project construction scheme, and then implement the second project, In this way, continuously improve the scheme and implement n pieces until the goal of zero defect is achieved and the idea of creating n + quality of the first piece is realized.

Implement the N + approval system for the first project, and make the first project demonstration as the starting point and foothold of creating a quality project.

Whether it is a project site with complete facilities and unified standardization, the formation of normal grid management, or the centralized management of reinforcement processing plant, Prefabrication Yard, concrete mixing plant and laboratory in order to comprehensively improve the technical management level of project construction, all highlight the quality requirements of the project for standardized construction.

The project management department has specially established a QC research group to actively carry out “micro innovation”, study and promote “four new” technologies, implement the production of steel bar shed standard chemical plant, and realize industrialized production through centralized processing.

“Through assembly line production, improve production efficiency on the premise of ensuring quality.

The pursuit of standardization by the project management department has penetrated into each construction process at each construction site.

On the other hand, according to the quantity and characteristics of reinforcement processing in the project, the reinforcement shed is divided into seven functional areas with clear functions and signs.

A big port was built in the hinterland of central Jiangxi, and long waves broke along the Lushui River.

On the one hand, actively implement the “mechanized replacement and automatic reduction”, and build the project reinforcement plant into an intelligent, automatic and large-scale assembly line production mode; At the same time, implement the instrumentalization, finalization and assembly of safety protection equipment and facilities.

With the in-depth implementation of the national strategy of promoting the development of the Yangtze River Economic Belt relying on the golden waterway, the comprehensive Wharf in the Hexi operation area of Zhangshu port area of Yichun port, located in the hinterland of central Jiangxi, is bravely standing at the forefront of the tide with the attitude of “trendsetter”, providing high-quality water transportation support for serving the development layout of “port city integration” of Zhangshu.

Taking innovative process as a breakthrough, in the process of project quality engineering creation, actively encourage innovative construction methods, introduce new technologies and processes, and carry out the application of applicable minimally invasive new construction technology, so as to significantly improve the project quality, safety and appearance quality of the project and form standardized construction achievements.

In addition, in order to strictly implement the grid management mode on the construction site, the project realizes the “horizontal to edge and vertical to the end” of safety, quality and civilized construction management on the construction site, assigns responsibilities to people, divides grid management areas, formulates on-site grid management charts and publicizes them on the wall, so as to realize the transformation from extensive management to fine management and control, and from a few people to joint efforts, The transformation from traditional management mode to information management has greatly improved the comprehensive management level of safety, quality, progress and environmental protection on the construction site.

Strictly control all links such as formwork, reinforcement, mix proportion, raw materials, admixtures, concrete pouring and curing, give full play to the linkage role of design and construction, and promote the realization of the goal of quality engineering..

In the standardized construction of small temporary construction sites, the project management department implements the “first piece system” management for different types of construction sites, systematically plans the site cleaning, leveling, hardening, functional zoning, placement of facilities and equipment, safety maintenance, safety warning, protection of operators and improvement of working environment, and arranges the site in combination with corporate culture and publicity, so as to form a clean, unified image Standard construction sites with unified standards, orderly construction, safety and civilization.

The project department shall prepare and implement the review and approval process of special construction scheme by referring to the guide for standardization of highway and water transportation, and strictly implement the special construction scheme.

With the development of society, the construction standardization of steel bar processing plant is becoming higher and higher.