The main machine is 2.5m wide, equipped with 2 1.5m irons, 2 0.5m irons, 2 1m irons and 2 0.25m irons

.

Xu Ke, a Yixing native of Jiangsu, is a leading engineer in the WeChat official account of the “asphalt pavement”, and is the chief engineer of Guangdong crystal Highway Engineering Group Co., Ltd., focusing on the construction management of asphalt pavement

.

Contact wechat: drxuke 1978 classic book of asphalt pavement industry | identify QR code for free reading, praise for China’s asphalt pavement technology!.

.

Among them, the inner curb is 1.25m, the overtaking lane is 3.75m, the main lane is 3.75m, the heavy lane is 3.75m, and the outer curb and hard shoulder are 3M

.

The following is an example of a single three lane asphalt pavement with a clear width of 15.5m

.

It is said that asymmetrical panels may affect the paving effect at specific locations

.

Some paver manufacturers advocate symmetrical panels

.

In the actual construction, due to the width and splicing conditions of the fixed screed of the paving equipment, the problem of longitudinal hot joint is quite complex

.

Setting mode: one machine for 7.5m, main machine + 2 1.5m boards + 2 1m boards; one machine for 8m, main machine + 2 1.5m boards + 2 1m boards + 2 0.25m boards

.

During the construction of the lower layer of asphalt pavement, the 7.5m machine goes to the inside; during the construction of the middle layer of asphalt pavement, the 8m machine goes to the inside; during the construction of the upper layer of asphalt pavement, the 7.5m machine goes to the inside again

.

Setting mode 2: one machine for 8.75m, main machine + 2 pieces of 1.5m board + 2 pieces of 1m board + 2 pieces of 0.5m board + 1 piece of 0.25m board; one machine for 6.75m, main machine + 2 pieces of 1.5m board + 2 pieces of 0.5m board + 1 piece of 0.25m board

.

But in reality, few people pay attention to the paver walking mode at different levels; whether the concrete construction is carried out according to the principle of staggered joints is an unknown problem

.

Because the traffic markings of main lane and heavy lane are located at 8.75 meters, there are two kinds of longitudinal hot joint setting methods

.

Introduction in the construction of asphalt pavement, two pavers, one in front of the other in the back of the paver, belong to the conventional technology, and the joint produced is called longitudinal hot joint

.

During the construction of each layer of asphalt pavement, the 8.75m machine should go inside, so as to ensure that the longitudinal hot joint position of each layer is at the traffic marking position

.

In parallel paving, there are many ways to adjust the paving width: adjusting the overlapping width of the two machines; removing the side plate, adjusting the feeding manually, increasing the paving range, etc

.

Two Volvo Construction Machinery abg7820b asphalt pavers are used for operation

.

When purchasing or leasing asphalt pavers, they are equipped with the combination of irons required by the standard paving width, which is generally adjusted within the scope of this resource; at the same time, limited by the connection mode of the irons, there is no infinite cascade mode

.

Therefore, for a specific paver, the paveable width data is basically fixed

.

Because in high-grade highway, the fixed screed paving equipment is used in most cases; at the same time, it involves the construction conversion of the lower, middle and upper layers; it must be spliced in advance to determine the width, which makes the longitudinal hot joint setting a relatively complex problem

.

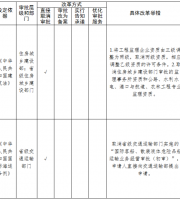

The standard paving width of the equipment is 9m, and the layout of the screed is shown in the figure below

.

The staggered longitudinal hot joints are realized by staggering pavers with different widths at different levels

.

As for the principle of setting the position of longitudinal hot joint, all kinds of literature and data are vague, so this paper discusses it

.

The voting is over

.

This should be the current mainstream longitudinal hot joint setting method

.

Principle according to the construction experience and theoretical analysis, the setting of longitudinal hot joint of asphalt pavement must follow the following principles: first, the positions of two longitudinal hot joints of adjacent layers must be staggered, at least 30-50cm; second, the longitudinal hot joint should be set at the traffic marking position as far as possible; third, the position of longitudinal hot joint can be in the middle of the lane, but never in the track belt

.