Common problems in the treatment of filling and excavation junction: standardized construction requirements: the filling in the half filling and half excavation section shall be filled in layers according to the design requirements.

When the cross slope of the natural slope is steeper than 1:5, before filling the filling and excavation junction and the half filling and half excavation section, dig upward from the foot of the filling slope into an inward inclined step with a width of no less than 2m.

The edges and corners shall be compacted mainly with large roller and with small compaction machines and tools..

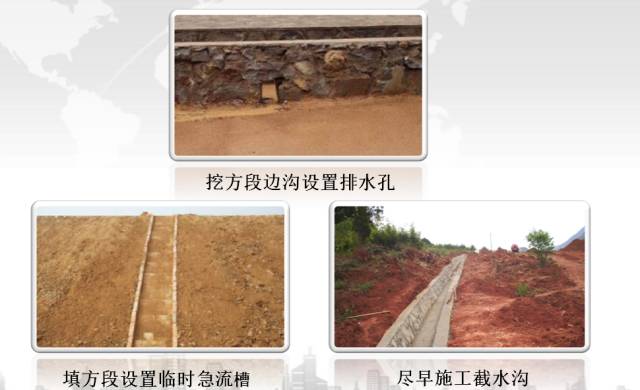

2、 General subgrade construction 1 ① common problems of temporary drainage in soil cutting excavation: standardized construction requirements: complete temporary drainage facilities to ensure that there is no ponding on the construction surface, and the intercepting ditch should be connected with the drainage system smoothly with smooth water flow.

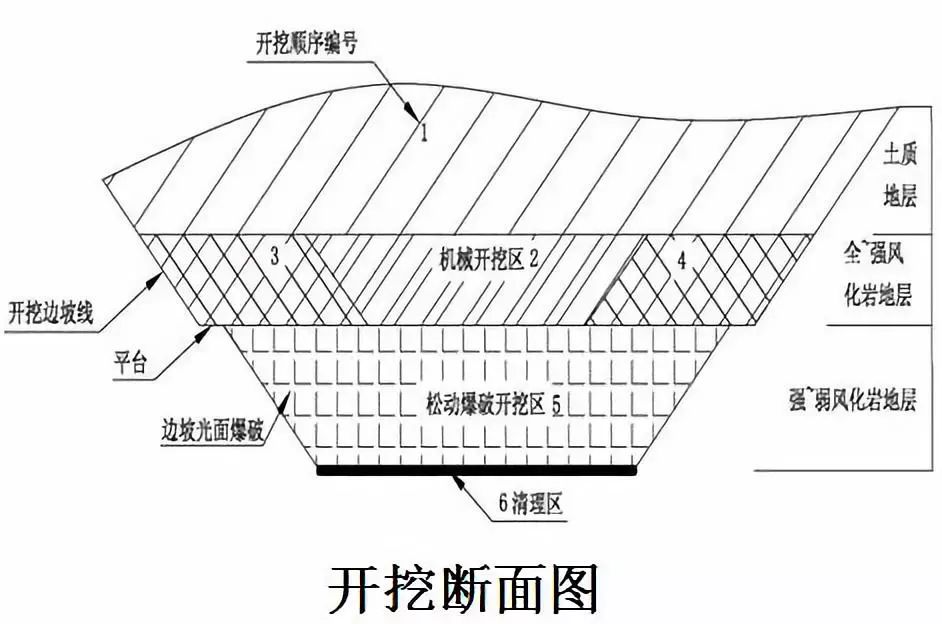

② Excavation method: common problems: standardized construction requirements: the earth excavation and transportation must be carried out in order from top to bottom.

It is strictly prohibited to excavate the bottom.

5.

Common problems in Stone Filled Subgrade Construction: standardized construction requirements: the particle size of filler shall not be greater than 50cm and shall not exceed 2 / 3 of the layer thickness.

The quality of subgrade also determines the quality of pavement, and the most direct impact is traffic and our personal safety, Today, this article will study with you how to achieve standardized construction of highway subgrade! 1、 Construction preparation 1 General requirements before subgrade construction, on-site investigation and verification shall be carried out on the basis of a comprehensive understanding of design requirements and design disclosure.

Select the location of borrow and spoil areas on site.

The embankment slope shall be trimmed, dense, straight, flat and stable, and the curve shall be smooth.

The construction can be continued only when the slope of each layer meets the requirements of design slope rate.

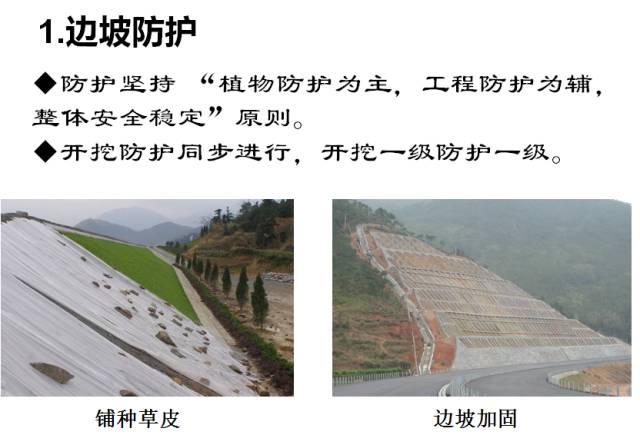

For the cutting section, the original vegetation from the slope excavation line to the intercepting ditch shall be retained.

3.

The Stone Filled Subgrade shall be equipped with high-power heavy-duty compaction machines and tools (impact rammers) for impact reinforcement, and vibratory rollers less than 14T shall not be used.

③ Common problems of slope trimming: standardized construction requirements: the excavation surface shall be trimmed every 3-4m of excavation height, and the slope shall be trimmed layer by layer from top to bottom.

② Common problems of fillers: standardized construction requirements: the strength and particle size of fillers shall meet the specification requirements; The soil with liquid limit greater than 50 and plasticity index greater than 26, as well as the soil with water content exceeding the provisions, shall not be directly used as Embankment Filler.

Filling subgrade construction ① filling: common problems standardized construction requirements: cross cut quantitative filling, filling in horizontal layers, the maximum loose paving thickness of class I highway shall not exceed 30cm, and that of other highways shall not exceed 50cm.

The type and quantity of construction machines and tools and personnel entering the site meet the site requirements; All kinds of technicians and operators meet the bidding commitment.

② Standardized construction requirements for safe construction: when drilling blast holes, pumice and dangerous rocks on the slope surface shall be cleaned; Warning personnel must be assigned around the warning area.

6.

Site planning, three supplies and one leveling, on-site signs, etc.

Click the “blue word” above to follow us! Highway subgrade is a very important part of highway engineering, and sufficient stability and durability are essential.

The elevation of the bedrock surface of the roadbed after excavation shall meet the design elevation requirements.

There shall be no loose and dangerous stones on the slope.

Sludge, swamp soil, frozen soil, organic soil, turf soil, domestic garbage, tree roots and soil containing decaying substances shall not be used.

Within 40cm below the roadbed bottom, the particle size of filler shall be less than 15cm.

Fillers with different properties shall be filled horizontally and in sections and compacted in layers.

The width of each layer of embankment fill shall be 30 cm wider than the design width on each side.

The humus, topsoil and turf on the original surface within the road width shall be cleaned, and the filling section shall be leveled and compacted according to the design requirements.

2.

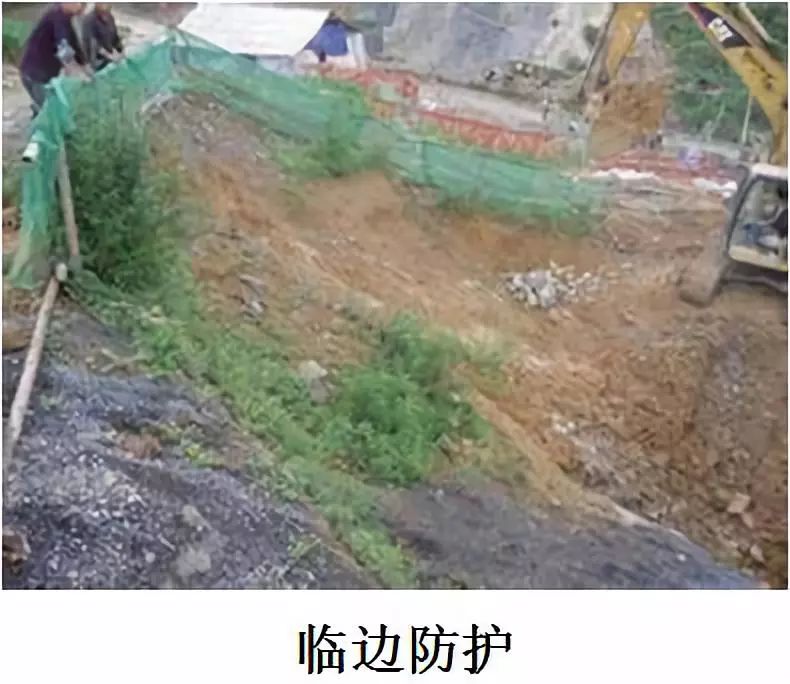

④ Common problems in safe construction: standardized construction requirements: the edge, cliff and pit opening shall be protected, and various safety warning signs shall be set according to the site conditions.

Before commencement, the quality, environmental protection and safety management system and quality inspection system must be established and improved, and pre job training and technical and safety disclosure must be carried out for all kinds of construction teams and construction personnel.

It is strictly prohibited to pass under the slope during operation.

After the site investigation, the implementation construction organization design and special construction scheme shall be prepared and submitted for approval according to the design requirements, the contract and the actual situation of the site.

4.

Trees and shrubs within the scope of subgrade land cleared by the construction site shall be cut down or transplanted before surface clearing, and the cut trees shall be stacked outside the subgrade land and handled properly.

③ Common problems of leveling and compaction: standardized construction requirements: if the subgrade width is large, the grader shall be popularized for uniform leveling.

The spoil shall be cleaned in time.

Technical preparation, technical disclosure, pre job technical training, supplement and unification of various test, inspection, process handover and other forms, prepare and collect various data catalogue, survey and setting out: traverse retest, leveling retest, midline retest and cross-section retest, select representative sections for test, and summarize construction technology and quality control measures.

Stone cutting excavation ① common problems of excavation method: standardized construction requirements: the stone excavation slope shall be straight, smooth and flat.

The full width of Subgrade in the same horizontal layer shall be filled with the same filler, and mixed filling is not allowed.

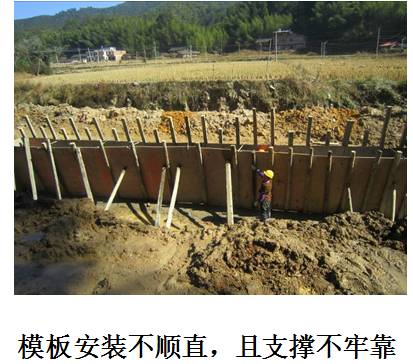

Backfilling of abutment back of structures ① filling requirements: common problems standardized construction requirements: the backfilling of abutment, culvert abutment and wall back must use permeable materials, inorganic binder, etc., and should be filled with natural gravel and stone slag.

It is not allowed to excavate indiscriminately, over excavate and under excavate.

On the one hand, it is guaranteed by perfect design, on the other hand, it is realized by scientific and rigorous construction methods.

3.

Warning signs shall be set under the spoil and the roads within the danger range of rolling stones.

2.

If it is too high, it shall be chiseled; If it is too low, it shall be filled with excavated stone chips or lime soil gravel and compacted.

The roadbed must be uniform and dense, and the thickness of the last layer on the top of the roadbed after compaction shall not be less than 10cm; The surface of the roadbed must be made into a crown cross slope consistent with the pavement, and the crown cross slope is about 3%; Large roller is recommended for large-scale filling of soil embankment.

② Rolling requirements common problems standardized construction requirements: mark the loose paving thickness mark line of each layer with paint, and fill in layers.

4.