That is RX = ry = 1.

Key and difficult analysis difficulties: 1.

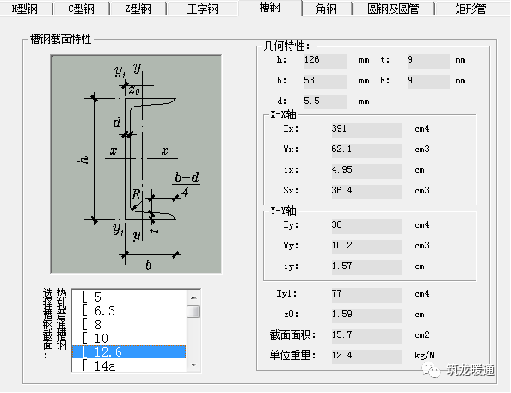

The design value of tensile strength of steel adopts the data of steel Q235, which is 215n / mm2, that is, f = 215n / mm2; By substituting the data into the cross arm bending strength formula, we can know whether the checked material model meets the stress requirements..

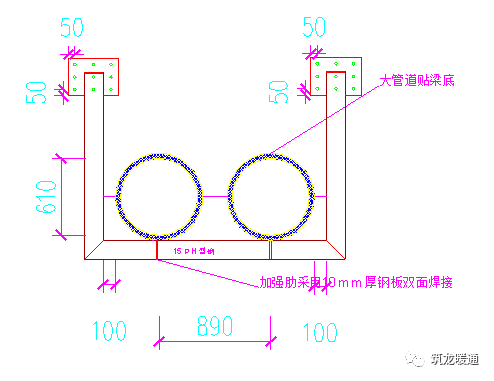

The weight of 4.8m dn400 seamless steel pipe: M = 4.8 * weight of full water per M = 4.8 * 230 = 1104kg, so the stress f = m * g = 11040n (4) load calculation.

It can be seen from the right table that Wx = 0.0621mm3wy = 0.0102mm3 is the increased safety factor.

Design load vertical load: considering factors such as manufacturing and installation, the standard load of support and hanger spacing is multiplied by the load partial factor of 1.35; Horizontal load: the horizontal load is calculated as 0.3 times of the vertical load; Wind load is not considered.

The spacing between supports is 4.8m, that is, each support is equivalent to the weight of 4.8m pipeline.

The calculated pipe weight is calculated according to the pipe weight, full pipe water weight, insulation layer weight and 10% additional weight (pipe connectors, etc.) within the distance between the designed pipe supports and hangers; 2.

Because the standard load MK = 884951n * mm, the vertical load MX = 1.35mk, and the horizontal load is calculated according to 0.3 times of the vertical load, That is, the horizontal load my = 0.3mx.

Select economical and reliable supports; Difficulties: 2.

The pipeline system is complex, the support forms are diverse, the selection is difficult to grasp, and the support is easy to deform, resulting in hidden dangers; Measures: 1.

MX, my ‒ bending moment of the checked section around the x-axis and y-axis (n · mm) Wx, WY ‒ net section resistance moment of the checked section to the x-axis and y-axis (mm) ³) F ‒ design value of bending and tensile strength of steel (n / mm) ²) 4.

3.

1.

Made of high-quality steel; 2.

The plastic development coefficient of the section is taken as 1.

Stress analysis diagram of concentrated stress: stress analysis diagram of uniformly distributed load: bending moment diagram after superposition of the two: it can be seen from the diagram that the position of the most unfavorable point is selected as 1 / 2 of the most unfavorable point for convenient calculation.

Its unit weight is 12.4kg/m, so its uniformly distributed load is 0.124n/mm; The stress of channel steel cross arm is the superposition of two concentrated stresses and a uniformly distributed load.

Large pipe diameter and concentrated stress; The number of supports is huge and there are many potential safety hazards; Measures: 1.

Source: the copyright of China Construction Third Engineering Bureau and Baidu Library belongs to the original author.

Calculation of flexural strength of cross arm the flexural strength of cross arm with horizontal thrust is calculated according to the following formula: Rx, ry ‒ section plastic development coefficient 1) when bearing static load or indirect dynamic load, RX = ry = 1.05.

Carry out anti-corrosion treatment for welds and flaw detection if necessary; 2.

Therefore, the standard load of the support MK = 88495n · mm can be obtained according to the formula.

2) When bearing dynamic load directly, RX = ry = 1.

When calculating, 10kg shall be taken as the base, that is, 10kg shall be calculated if it is less than 10kg.

Type selection of supports and hangers 1.

The example analysis now takes two dn400 seamless steel pipes as the support for example: (1) the specific data of the support is shown in the above figure, and the spacing of the support is set to 4.8m; (2) Calculation of pipe weight: refer to the hardware manual and calculate the following table: pipe diameter (mm), wall thickness (m), outer diameter (m), inner diameter (m), pipe weight per M (kg), water weight per M (kg), insulation weight per M (kg), full water weight per M (kg) 4000.0090.4260.40892.554130.7403.741227.035 (3).

Here, when the material used is rigid and non plastic.

According to the support scheme, establish a model, analyze the stress situation and find out the most unfavorable point; Here, let’s assume that 12.6# channel steel is used, and refer to the hardware manual.

Carry out technical disclosure to welders and select skilled welders for full-time production; Ensure welding quality and efficiency; 2.

Calculate the full load and analyze the stress of the support; 3.