IV.

Case comments ↑ to realize the installation without adjusting gaskets, the first thing is to ensure the accuracy of civil construction and ensure that the elevation error of foundation embedded parts is within the design requirements.

↑ the bolt is not exposed ↑ the installation of the circuit breaker support meets the requirements of the manufacturer ↑ the space between the base of the circuit breaker support and the foundation plane is filled with cement mortar, which does not meet the requirements of the manufacturer.

Key points of specification: the grounding of each electrical device shall be connected with the grounding trunk line with a separate grounding wire.

↑ the gap between GIS base and foundation embedded parts is large, but no gasket is added.

2.

Example comments ↑ key points of installation process requirements ③: the connection between lightning rod (belt) and down lead shall be welded or heat flux (exothermic) welding.

Key points of process requirements ⑤: the grounding of each electrical device shall be connected with the grounding busbar or grounding trunk line with a separate grounding wire.

Key points of specification: the following metal parts of electrical devices shall be grounded or connected to neutral: metal frames and bases of panels (cabinets, boxes) for power distribution, control and protection and operation console.

Key points of specification: the welding of grounding body (wire) shall adopt lap welding, and its lap length must comply with the following provisions: the flat steel shall be twice its width (and at least three edges shall be welded).

Example comments ↑ equipment wiring specification ↑ jumper specification ↑ the bending radian of flexible conductors between equipment is inconsistent and arranged irregularly.

The alarm, closing and locking values of density relay meet the regulations; The transmission of electrical circuit is correct.

2、 Bus installation 1.

Example comments ↑ structural support grounding height, consistent orientation ↑ equipment grounding height, consistent orientation ↑ grounding production is beautiful and the identification is obvious.

The pressure, leakage rate and water content of sulfur hexafluoride gas shall meet the regulations.

Several electrical devices requiring grounding shall not be connected in series in one grounding wire.

Case comments ↑ key points of series grounding process requirements of casing base ⑥: important equipment and equipment framework shall have two grounding downleads connected to different places of the main grounding grid, and each grounding downlead shall meet the requirements of thermal stability and mechanical strength, and the connecting lead shall be convenient for regular inspection and test..

Round steel is 6 times its diameter.

Key points of tubular bus installation process requirements: the axes of three-phase bus pipe sections shall be parallel to each other, the elevation shall be consistent, and the deflection shall meet the design and specification requirements; The appearance is smooth, the welding process is good, and the distance between the weld junction and the edge of the support is ≥ 50mm; The phase color marks are complete and correct.

Case comments ↑ no welding process is adopted between the independent lightning rod and the down lead.

Key points of specification: the linkage of circuit breaker and its operating mechanism shall be normal without jamming; Opening and closing indication is correct; The action of auxiliary switch is reliable and correct.

Key points of specification: the connection between lightning rod (belt) and down lead shall be welded.

When flat steel is welded with steel pipe, flat steel and angle steel, in order to connect reliably, in addition to welding on both sides of its contact part, it shall be welded with arc (or right angle) clips bent by the steel strip or directly bent into arc (or right angle) by the steel strip itself and welded with steel pipe (or angle steel).

When there are no regulations in the design, it shall not be less than 0.6m; The overlapping of steel grounding body shall adopt overlapping welding, and the overlapping length and welding method shall meet the specification requirements.

In addition, bolt adjustment equipment shall be selected as far as possible during equipment selection to facilitate on-site adjustment.

After grounding welding, anti-corrosion treatment shall be carried out in time, and anti-corrosion treatment shall also be carried out for the cut section of steel and galvanized steel where the galvanized layer is damaged during welding.

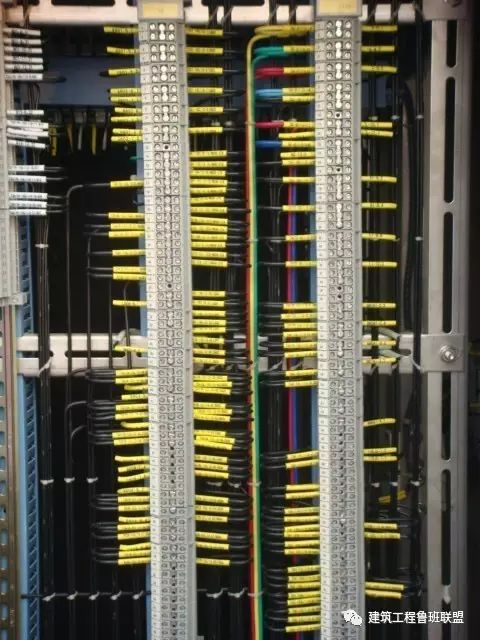

key points of screen and cabinet installation process requirements: the screen surface of control, protection, automation and DC line-up screen and cabinet shall be flat, the screen and cabinet surface error shall meet the flatness of adjacent two screens, and the gap between adjacent screens and cabinets shall be ≤ 1.5mm; It shall be fixed firmly with bolts; There are naming numbers on the front and back of the panel and cabinet, and the components in the panel and cabinet (terminal box and local cabinet) are complete and clear; The body of the panel cabinet (terminal box and local cabinet) shall be reliably grounded, and the openable door of the panel cabinet (terminal box and local cabinet) shall be reliably connected and grounded with soft copper wire.

Guide reading combined with examples to interpret the process and practice of substation electrical engineering construction.

It is strictly prohibited to connect several electrical devices to be grounded in series in one grounding wire.

Key points of specification: the grounding device of power plant and substation shall be connected with the lightning conductor of the line, and there shall be connection points convenient for separation.

1、 Key points of equipment installation process requirements: the equipment installation meets the specifications and the requirements of the manufacturer, the action of the rotating point of the equipment is flexible, correct and reliable, the contact is good, the indication is correct, the electrical and mechanical locking is reliable, all seals are well sealed, the porcelain parts are free of damage and crack, and the appearance of the equipment is free of damage and pollution.

Mainly from the following seven aspects: ① equipment installation, ② bus installation, ③ panel and cabinet installation, ④ grounding device construction, ⑤ cable laying, ⑥ fire blocking and ⑦ secondary wiring, the main construction process requirements affecting the project quality are interpreted.

Key points ④: the grounding position of equipment and structural support shall be standardized and unified, the connection shall be reliable, the fabrication shall be beautiful, and the grounding identification shall be obvious and correct.

↑ the screen surface is uneven ↑ the gap between adjacent panels and cabinets exceeds the standard ↑ the screen and cabinet door is not reliably connected to the ground with soft copper wire.

Key points of flexible bus installation process: the conductor shall be free of looseness, strand breakage and damage, and the expanded conductor shall be free of depression and deformation; The flexible conductors in the equipment room shall be bent naturally, with consistent radian and orderly arrangement; The sag of flexible bus and equipment connection shall be consistent, elastic, neat and beautiful; The jumper shall be smooth and the sag of three-phase jumper shall be consistent.

key points of construction process requirements of grounding device ①: the buried depth of grounding body shall meet the design regulations.

Example comments ↑ installation specification III.

When the round steel is connected with the flat steel, its length is 6 times of the diameter of the round steel.

Example comments ↑ installation specification of panel cabinet ↑ binding and fixing of iron wire, non-standard.

Example comments ↑ specification for lap welding of grounding body ↑ insufficient lap area of grounding flat steel ↑ key points of incomplete welding process requirements ②: the grounding device of substation shall be connected with the lightning conductor of the line, and there shall be connection points convenient for separation.