The project cost increases less, which can significantly shorten the construction period of the ditch.

Your ability is the strength of the enterprise, and the strength of the enterprise is inseparable from your excellence.

Prefabrication and assembly technology has the characteristics of reliable structural quality, high degree of mechanization and high construction efficiency.

Take the shield tunnel segment as the comparison object, the thickness of the segment (segment) is 300mm, and the reinforcement is 150kg / m ³, Taking 15km transportation as an example, the unit price of C50 segment is about 1000 yuan / m3.

While improving the quality of the tunnel structure, It also greatly improves the installation efficiency of cables and other ancillary facilities in the tunnel, increases the aesthetic degree in the tunnel, and provides a good guarantee for the quality control of power cable tunnel.

Open cut and cast-in-place cable tunnels have many on-site operation processes, many cross operations and long construction period.

After adopting the design and construction technology of pipe joint factory prefabrication and on-site assembly, the manual workload can be significantly reduced and the mechanized construction level of tunnel and cable trench engineering can be improved.

Under the same conditions, the cost of the structural body of the open cut tunnel is basically the same as that of the cast-in-place tunnel.

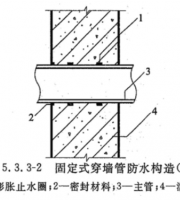

The prefabricated tunnel has more sealing rubber strips between pipe sections and prestressed steel tendons for longitudinal tightness than the cast-in-place tunnel.

Transcendence is a realm.

It meets the requirements of the scientific outlook on development.

It is preliminarily estimated that the cost is about 8% ~ 10% of the body cost and 4% ~ 5% of the whole project cost.

The original surface quality control points are concentrated in the linear shape such as the pipe section joint, which reduces the cost caused by the quality deviation in the construction process, and the flatness of the inner wall of the pipe can be accurate to mm level.

Welcome to the concrete technology exchange! Scan QR code and pay attention to the official wechat account of concrete technology exchange..

4.

Improve the overall quality of the tunnel and cable trench structure.

Improve the mechanization degree of tunnel and cable trench construction.

New opportunities are new challenges.

Because the tunnel structure adopts factory prefabrication, it greatly improves the working environment of constructors, reduces the construction period of on-site construction operation, and meets the social development needs of “people-oriented”.

Under the existing technical conditions, the cable structures are still mainly manual in the stages of structural pouring and support installation, which has the characteristics of large on-site workload, poor labor protection, and high correlation between quality and workers’ technical level.

Due to the factory prefabrication, the waterproof and durability quality of the pipe section can be greatly improved.

Its application in power cable structure engineering can also show many technical advantages.

3.

Transcendence is a kind of spirit.

Taking the whole line excavation of foundation pit (groove) and the construction of all works at intervals and sections as an example, the total construction period of tunnel main body plus waterproof construction is more than 90 days, while the process of prefabrication and assembly of tunnel main body and completion of deformation joint construction on site can control the construction period within 40 days and significantly shorten the construction period.

1.

2.