Construction process flow 2.

Construction process flow 2.

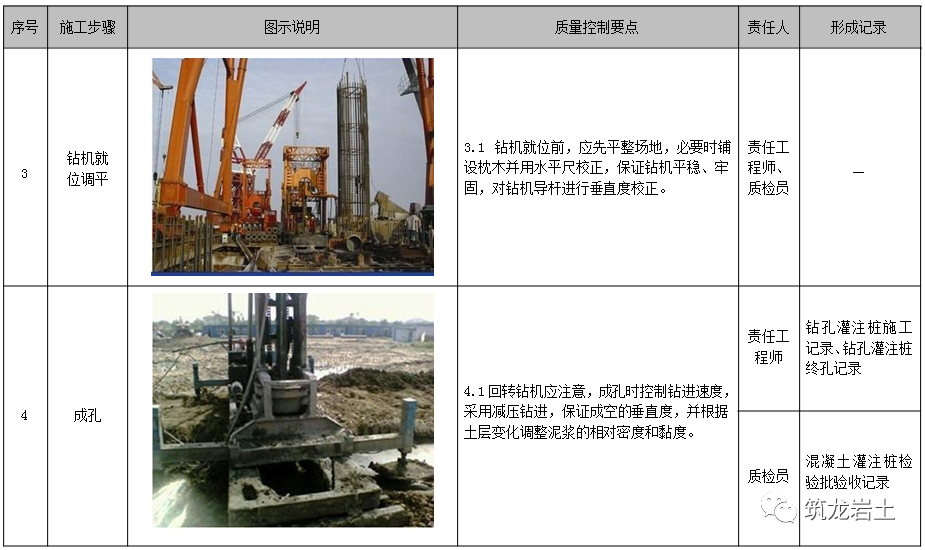

Construction process flow 2 Construction process standard drawing (2) rotary drilling bored pile 1.

⑤ The bearing capacity of engineering piles shall be tested.

⑥ The quality of pile body shall be inspected.

Construction process flow 2.

⑨ After the completion of filling construction, the elevation, slope gradient, compaction degree, etc.

The final acceptance can be carried out after the construction of all piles is completed and the cushion cap or bottom plate is excavated to the design elevation.

When the total number of piles is less than 50, it shall not be less than 2.

Sampling by sand filling method shall be the full depth after compaction of each layer.

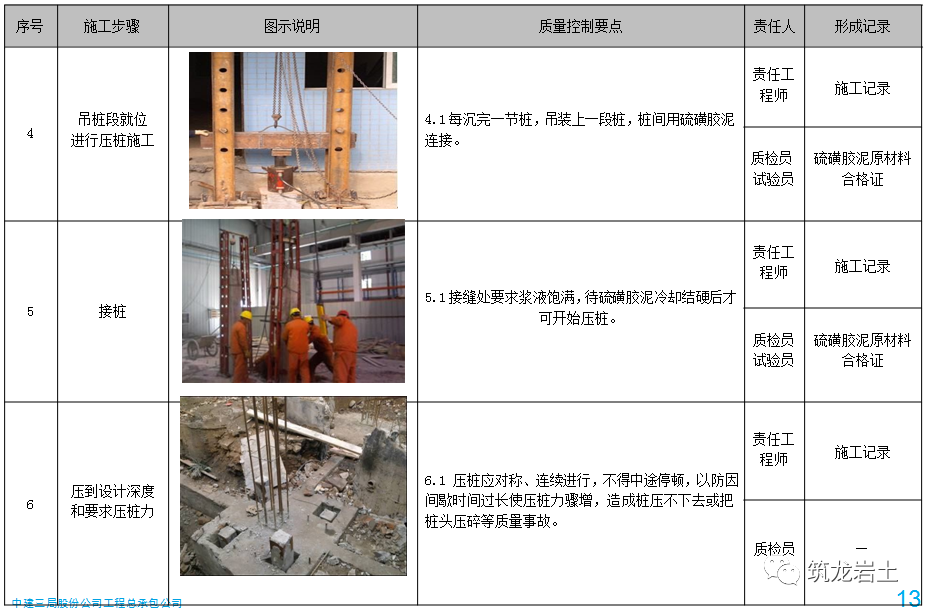

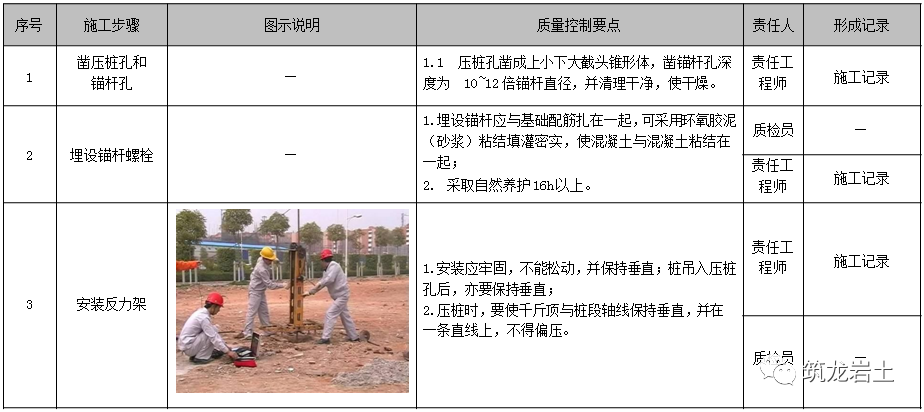

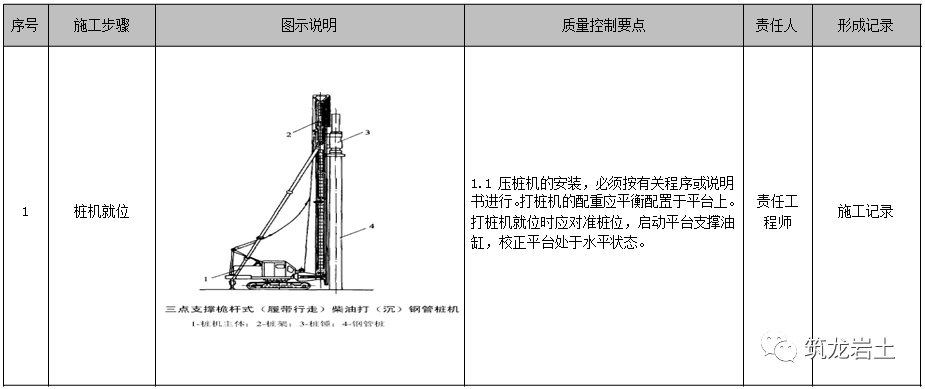

01 anchor static pressure pile 1.

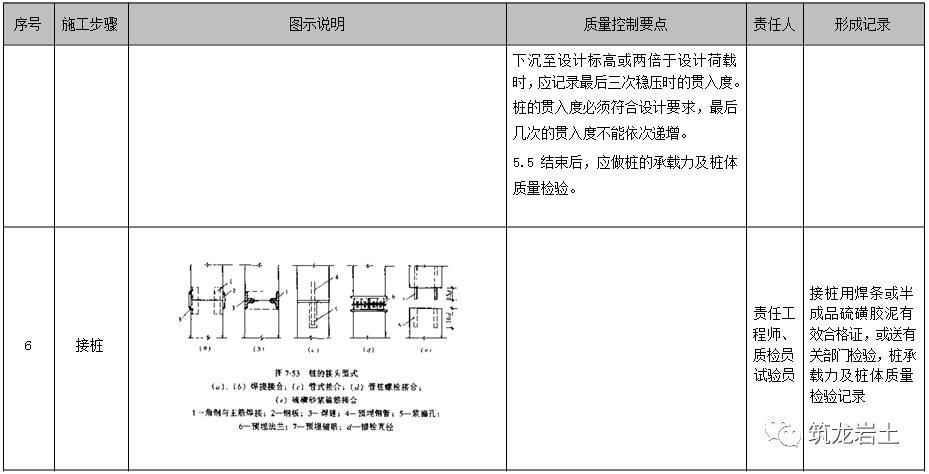

Pre control measures 02 reinforced concrete precast pile 1.

Source: the copyright of the general contracting company of China Construction Third Engineering Bureau belongs to the original author (PS: click the picture to zoom in).

Construction process standard figure 3.

Process flow correlation Figure 2.

For cast-in-place piles with design grade of class A or complex geological conditions and low reliability of finished inspection quality, the number of sampling inspection shall not be less than 30% of the total and shall not be less than 20; The sampling inspection quantity of other pile foundation works shall not be less than 20% of the total, and shall not be less than 10; For precast concrete piles and cast-in-place piles above the groundwater level and verified after hole completion, the inspection quantity shall not be less than 10% of the total number of piles, and shall not be less than 10.

Process flow association diagram 2.

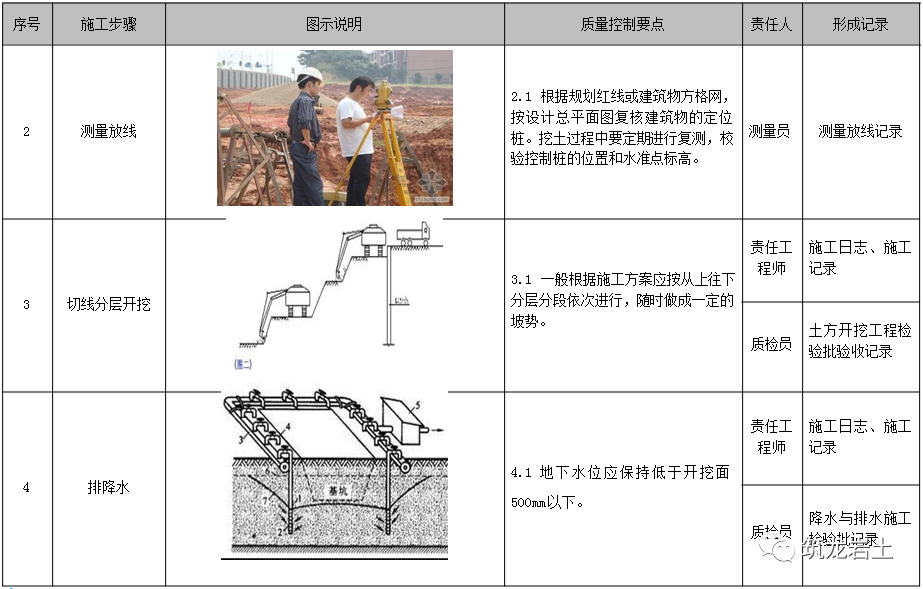

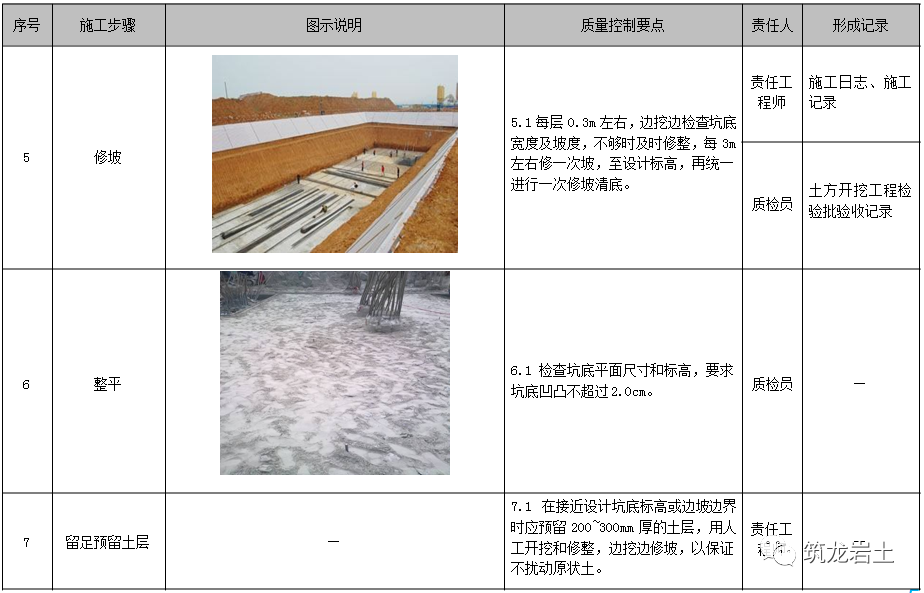

② The control of earth excavation mainly includes the inspection of excavation elevation, section size, grading and drainage.

Click on the picture of pre control measures.

The deviation of the inclination of the inclined pile shall not be greater than 15% of the tangent of the inclination angle (the included angle between the longitudinal center line of the inclined pile and the plumb line).

⑦ For foundation pit and indoor fill, 1 group of samples shall be taken for each layer according to 100-500 ㎡; The site shall be leveled and filled, and one group of 400-900 M2 samples shall be taken for each layer; For the backfilling of foundation pit and pipe trench, one group shall be sampled every 20-50m, but not less than one group shall be sampled for each layer, and the sampling part shall be in the lower half of each layer after compaction.

The upper layer can be filled only after meeting the design requirements.

The elevation of pile top shall be at least 0.5m higher than the design elevation.

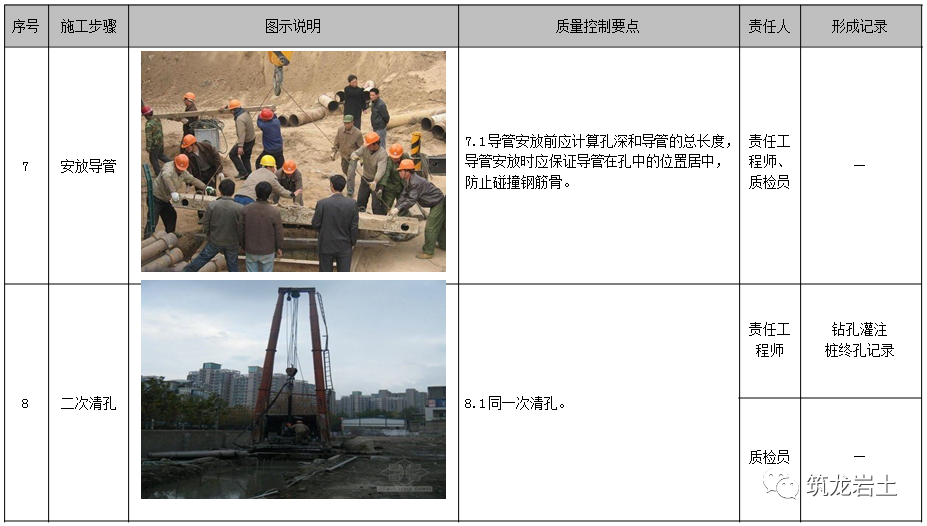

The hole cleaning quality of pile bottom shall be implemented according to different requirements of different pile forming processes.

The control content is mainly to review the positioning pile, axis, orientation and geometric dimension of the building.

Construction process flow 2.

Main control standard ① when the design elevation of pile top is the same as that of the construction site, or when it is possible to inspect the pile position after the pile foundation construction, the acceptance of pile foundation works shall be carried out after the construction is completed.

⑥ For the filling with compactness requirements, after compaction or compaction, the quality of each layer of backfill shall be inspected.

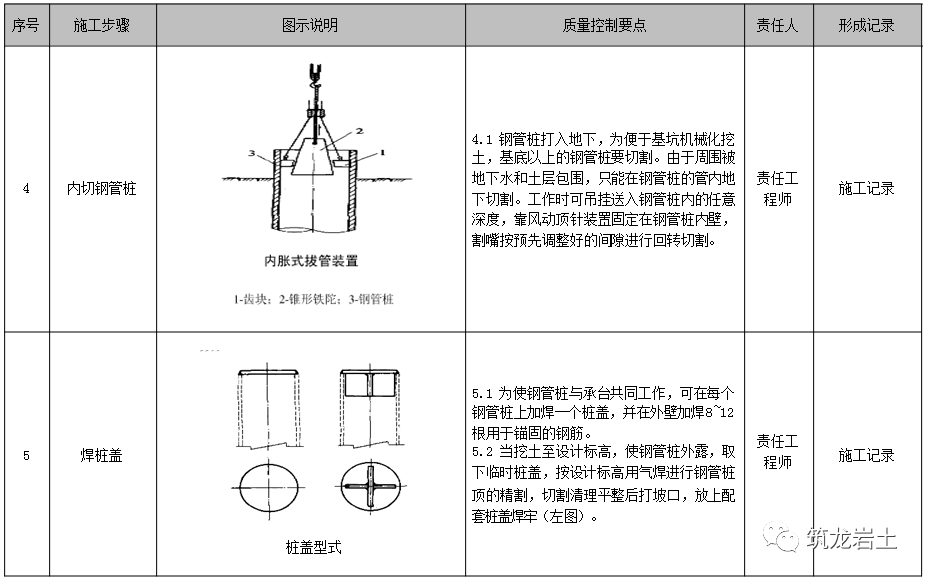

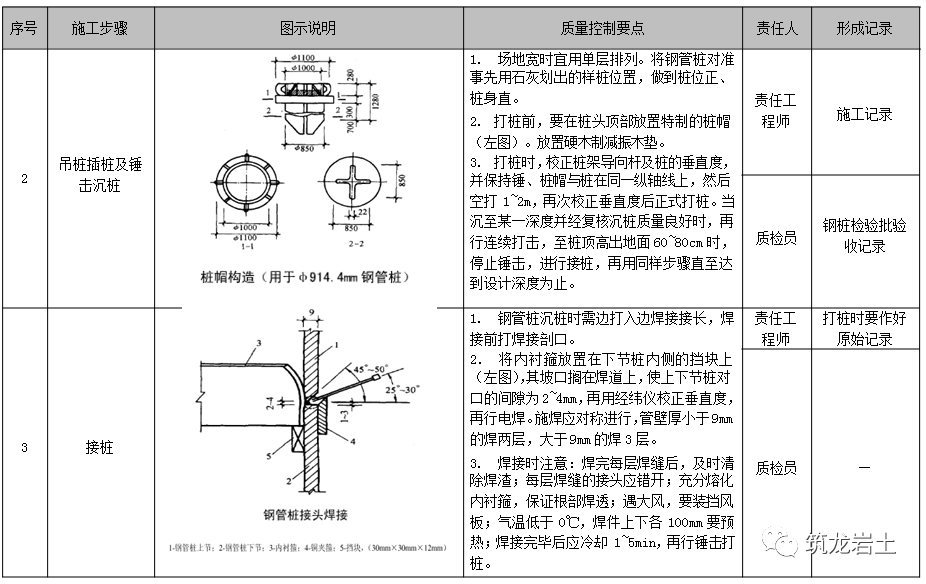

Pre control measures 03 steel pile 1.

For cast-in-place pile, the position of pile casing can be subject to intermediate acceptance.

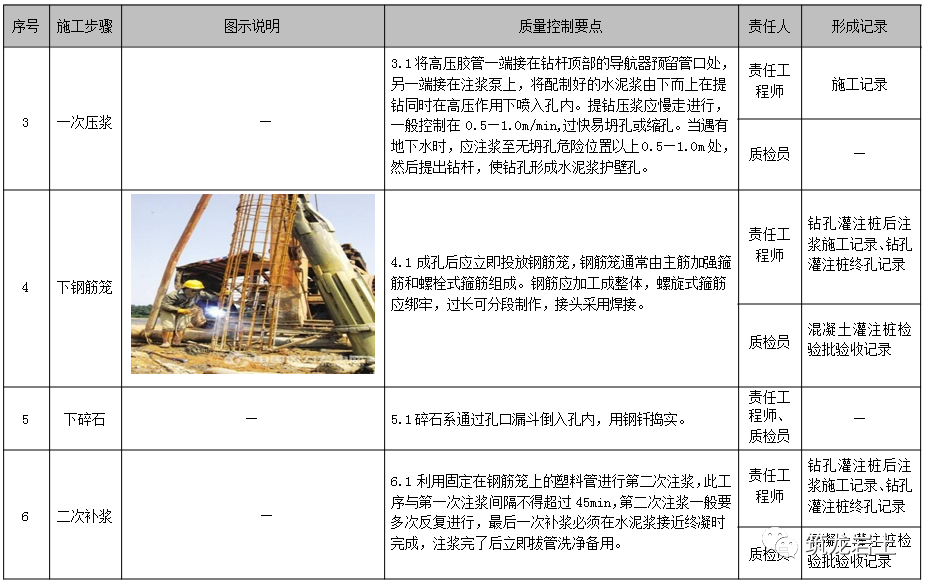

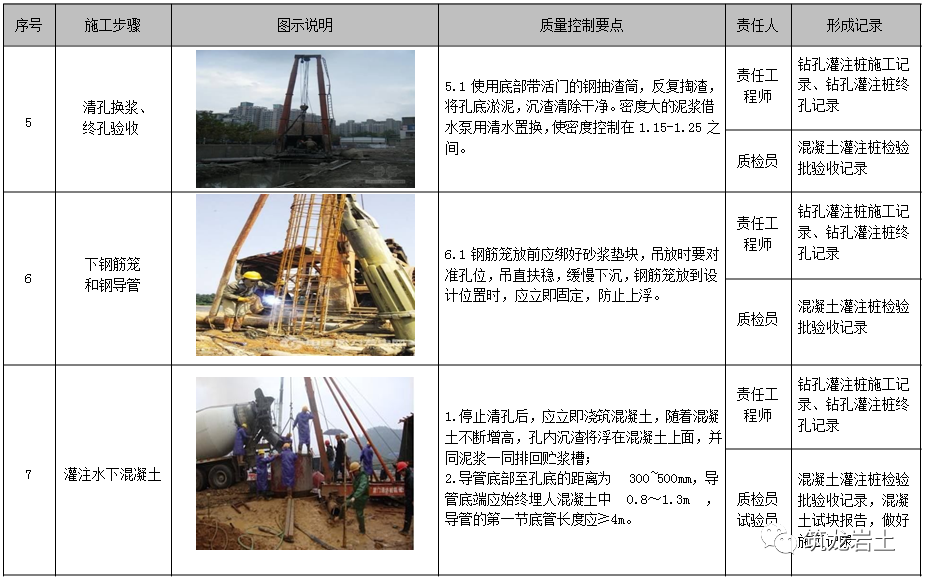

Construction process standard drawing (3) bored grouting pile 1.

Main control standard ① control of positioning and setting out.

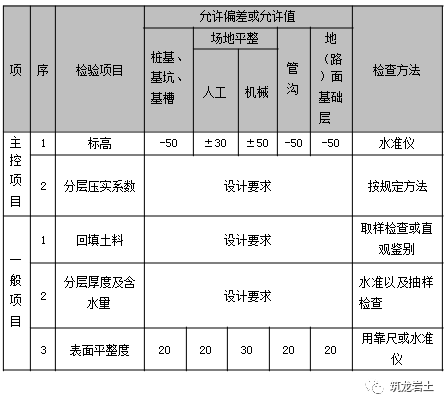

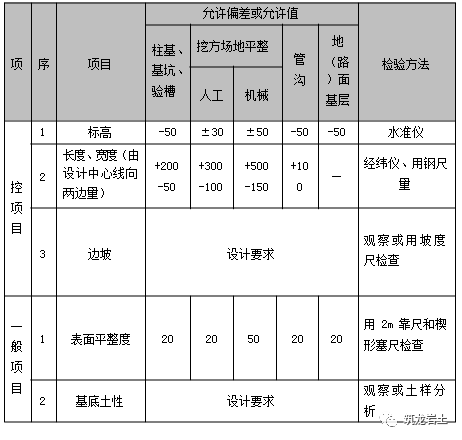

④ Quality inspection standard of earthwork excavation (see the table below) ⑤ drainage measures, filling thickness, water content control and compaction procedures of each layer shall be checked during filling.

Construction process standard drawing 3.

The number of inspection piles shall not be less than 1% of the total number, and shall not be less than 3.

no earthwork support 1.

The inspection standards are shown in the following table (mm), 01 earth excavation 1, construction process flow 2, construction process standard figure 3, pre control measures 02 earth backfilling 1, construction process flow 2 Construction process standard figure 3.

⑦ The quality, inspection items, batch and inspection methods of raw materials such as sand, stone, steel and cement shall comply with the provisions of the current national standards.

Construction process standard figure 3.

Construction process standard figure 3.

shall be checked.

I.

④ The pile position deviation of cast-in-place pile must be specified in the specification.

③ Acceptance of foundation pit (trench) after the excavation of foundation pit, relevant personnel from the construction unit, design unit, survey unit, supervision unit or construction unit shall jointly go to the site to inspect, identify and inspect the trench, check the geological data, check whether the foundation soil meets the requirements of engineering geological survey report and design drawings, and whether there is damage to the undisturbed soil structure or major disturbance.

For cast-in-place piles with grade a foundation design or complex geological conditions and low pile quality reliability, the static load test method shall be adopted for inspection.

Pile foundation 1.

Generally, the ring knife method is adopted.

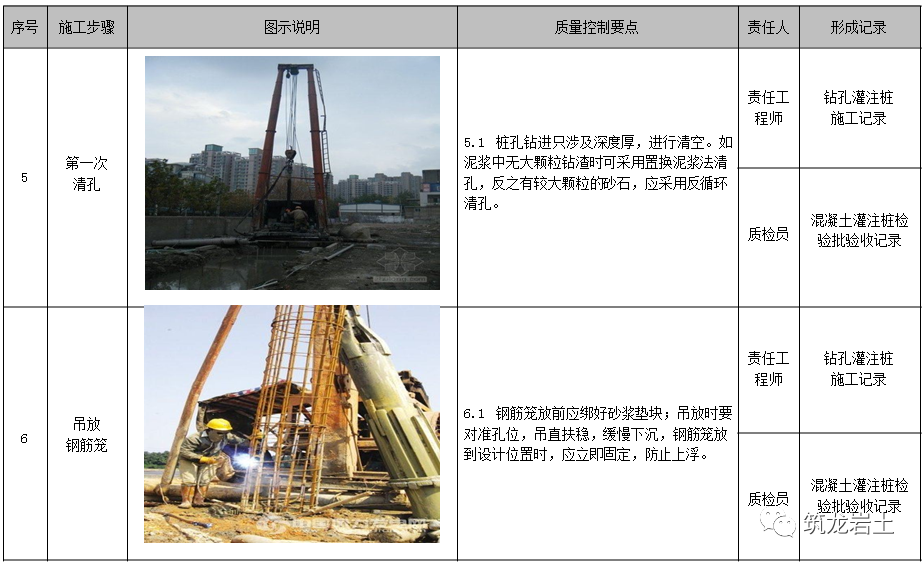

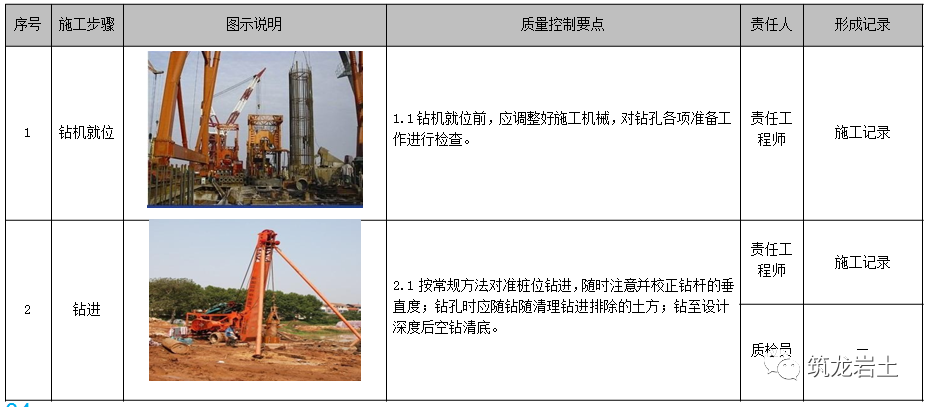

Pre control measures 04 concrete cast-in-place pile (1) impact drilling cast-in-place pile 1.

② When the design elevation of the pile top is lower than the elevation of the construction site and the pile position cannot be checked after the pile is sent, the driven pile can be subject to intermediate acceptance when the top of each pile is sunk to the elevation of the site.

⑧ The dry density of the compacted fill shall meet the design requirements by more than 90%, and the difference between the minimum value of the remaining 10% and the design value shall not be greater than 0.08t/m ³, And should not be concentrated.

Every 50m of pouring ³ There must be one group of test pieces, less than 50m ³ Each pile must have 1 set of test pieces.

There shall be no less than one under each column cushion cap.

Pre control measures II.

③ The pile position deviation of driven (pressed) pile (precast concrete square pile, pretensioned prestressed pipe pile and steel pile) must meet the specification requirements.

Construction process flow 2.