(7) Manually adjust the pile head reinforcement to the corresponding position according to the requirements of the drawing.

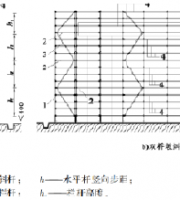

(Figure VI) (2) cut two lines at the upper and lower cutting marks on the soilless side with a cutting machine.

(3) The notch shall be cut and chiseled manually, and the depth shall be the thickness of the protective layer of the reinforcement.

(8) Pay attention to the protection of the acoustic pipe during construction.

When the construction is fast to the side of the slope, slow down, pay attention not to damage the main reinforcement, and use the air pick to peel off small pieces of concrete until all the main reinforcements are separated.

If the acoustic pipe extends too much or too long into the pile and cannot be lifted up after the pile is broken, cut the acoustic pipe with gas welding, and plug the upper opening of the acoustic pipe with cotton cloth immediately after cutting, Prevent debris such as stone chips from falling into the pipe to block the pipe and affect the detection of pile foundation.

2.

If the acoustic pipe protruding from the pile foundation is overwhelmed or deformed during hoisting or pile head chiseling, it shall be corrected in time.

Construction process 1 process flow: upper concrete breaking → measuring the elevation and cutting the pile protection → opening the gap → stripping out the reinforcement → deepening the gap → drilling top breaking → lifting off the broken body → chiseling away the residue → cleaning the pile head 2 technical requirements 1.

During the construction of the construction team, the marks shall be densified around the pile foundation according to the marks made by the survey team.

Because the supporting pile is close to the slope, it is inconvenient to construct on the side close to the slope, and the spacing between piles is small, so it can only be constructed from one side.

(4) The air pick peels off the protective layer of the upper reinforcement, peels the reinforcement from the concrete, and slightly bends the reinforcement to the outside for the convenience of subsequent construction.

Use the air pick to knock off the concrete block by block from the soilless side of the pile body.

(9) The foundation pit shall be cleaned, and the local uneven parts shall be trimmed and filled manually.

The thickness of the protective layer of the engineering pile reinforcement is 60mm.

Before the pile head chiseling construction, the surveyor shall accurately set out the design elevation of the pile top of each pile and mark it.

The engineering pile shall be excavated to the design elevation by machinery.

(4) The air pick peels off the protective layer of the upper reinforcement, peels the reinforcement from the concrete, and slightly bends the reinforcement to the outside for the convenience of subsequent construction.

After the pile head is disconnected and lifted out of the foundation pit, the construction team shall check whether the top surface of each pile is flat one by one.

The thickness of the protective layer of the reinforcement of the supporting pile is 50mm.

The cutting depth is slightly less than the thickness of the protective layer of the pile foundation reinforcement.

For example, when chiseling the pile head, pay attention not to damage the acoustic pipe in the pile.

When the height of bearing platform and crown beam is less than the anchorage length of reinforcement, the longitudinal reinforcement at the pile top can rise to the top of bearing platform and crown beam and then bend the straight hook to ensure the anchorage length.

After the pile head of pile foundation with acoustic pipe is disconnected and lifted out of the foundation pit, the construction team shall check whether the acoustic pipe on the top surface of each pile is exposed to the top surface of the pile one by one.

Engineering pile (1) the surveyor shall measure the elevation of the pile top with a level gauge, determine the position of the pile top required by the design, and set a 100mm reserved belt on the pile top 100mm deep into the bearing platform.

The cutting depth is slightly less than the thickness of the protective layer of the reinforcement of the pile foundation.

The acoustic pipe in the pile is arranged at 120 degrees and close to the inner ring of the main reinforcement.

During excavation, the pile body shall not be touched by machinery, and the soil 200mm around the pile shall be removed manually; Due to the dense spacing of supporting piles( A1000@1200 )And close to the slope, excavate mechanically to 200mm away from the pile, excavate the rest manually, and clean the soil between the piles.

If there is an uneven part of the pile top surface, it shall be chiseled with a steel chisel again.

After passing the detection, relevant units shall be organized to carry out pile foundation acceptance.

The cushion concrete shall be poured after being accepted by the supervising engineer.

5.

Do not damage the pile foundation reinforcement.

(1) The surveyors measure the elevation of the pile top (18.4m) with a level gauge, determine the position of the pile top required by the design, and set a 100mm cutting belt on the pile top 100mm deep into the crown beam.

Setting out and leveling shall be carried out according to the design elevation, and red paint shall be marked on the reinforcement and pile top to ensure the level of cushion..

(8) Pay attention to the protection of the acoustic pipe during construction.

The reinforcement shall not be damaged during chiseling.

Setting out and leveling shall be carried out according to the design elevation, and red paint shall be marked on the reinforcement and pile top to ensure the level of cushion.

Do not damage the reinforcement of the pile foundation.

2.

(3) Manually chisel the notch on the upper cutting line, the depth is the thickness of the reinforcement protective layer, and the reinforcement shall not be damaged during chiseling.

3.

(6) After the pile head is broken, the pile head shall be lifted out with a crane, the reserved concrete shall be chiseled manually to reach the pile head elevation required by the design, the scum at the pile head shall be removed and washed with water.

(10) After the pile foundation is tested to be qualified, the foundation pit shall be cleaned, and the local uneven parts shall be trimmed and filled manually.

(9) After the pile head is chiseled, small strain detection shall be carried out in different areas.

(7) Manually adjust the pile head reinforcement to the corresponding position according to the requirements of the drawing.

(6) Transport the concrete fragments to reach the pile head elevation required by the design, remove the scum at the pile head and wash it with water.

3 construction steps 1.

(5) Add plain concrete at the upper part of the top break, with the drill bit slightly upward, and the position is 100mm on the pile top line.

At the beginning, the steel drill can be driven to assist the construction.

6.

(5) Add plain concrete at the upper part of the top break, with the drill bit slightly upward, and the position is 100mm on the pile top line.

Before the pile head chiseling operation, ask the technicians whether there is an acoustic pipe in the pile foundation.

After chiseling out the acoustic pipe, temporarily seal it with a wooden plug to prevent the blockage caused by the falling of sundries.

If not, explain to the technicians and continue to chisel the pile head until the acoustic pipe is exposed.

During construction, always pay attention to the stability of the slope, stop the construction immediately in case of danger, take reinforcement measures for the slope, and continue the construction only after confirming the safety.

(2) Use a cutter to cut two lines at the upper and lower cutting marks.

At least four places of each pile shall be marked with red paint.

During the pile head chiseling operation, in order to protect the effective pile body, ring cutting and the next process shall be carried out 10cm above the pile top, and 10cm shall be reserved for manual chiseling, so as to ensure the accuracy of the height of the pile head extending into the bearing platform and the elevation of the top surface.

After chiseling out the acoustic pipe, temporarily seal it with a wooden plug to prevent the blockage caused by the falling of sundries.

The cushion concrete shall be poured after being accepted by the supervising engineer.

4.

Fixing Socket Cross Pin Nail Plate

7.