Interleaved construction can reduce the number of simultaneous construction operations and the number of workers, reduce the proportion of labor cost in the total construction cost, reduce the demand for skilled workers, and move forward to industrialization.

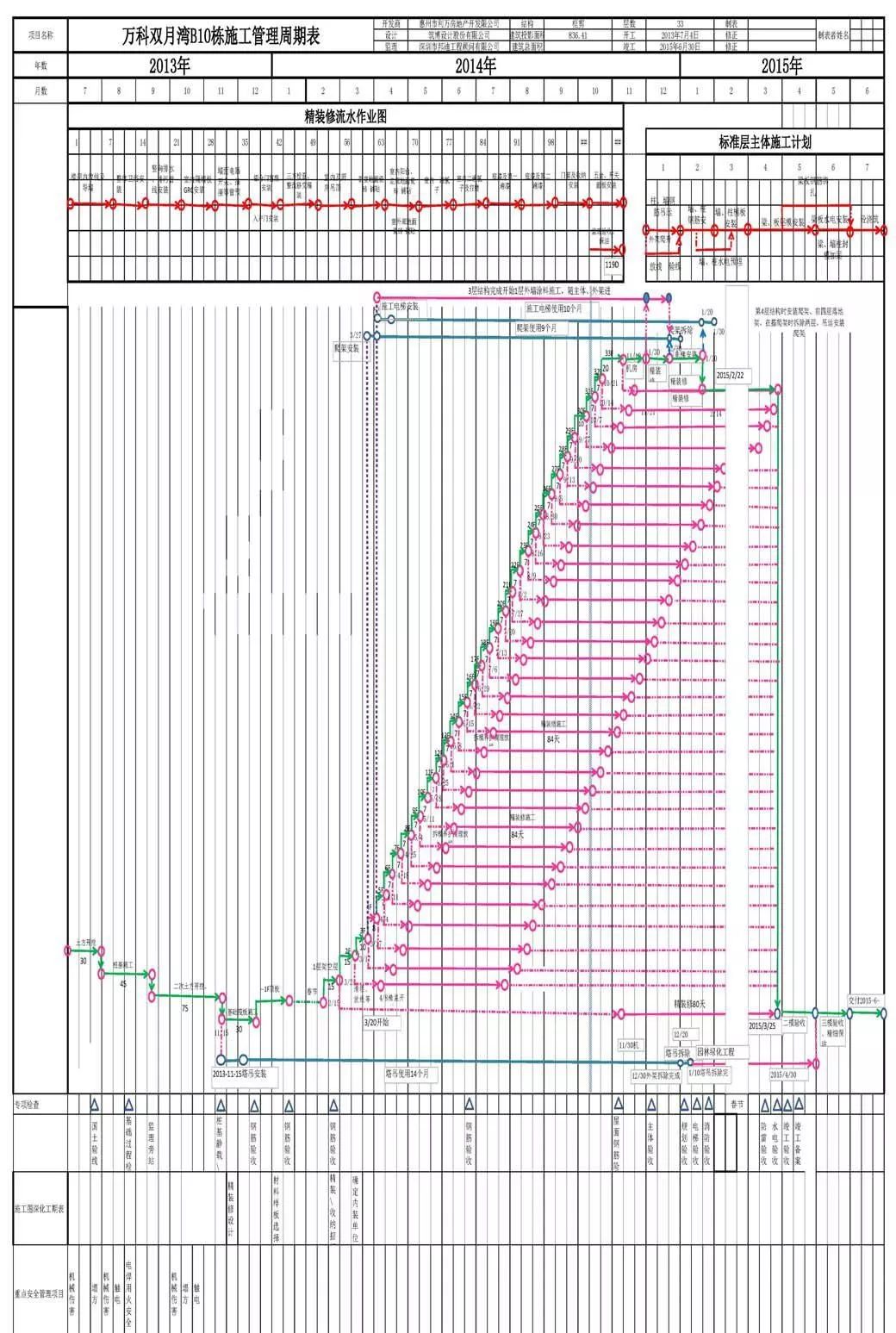

Process principle ➤ management principle the project construction management is led by the general contractor, responsible for the safety, quality and progress of the project construction (including the safety, quality and progress of each Party A’s subcontractors), until the completion of the fine decoration of the project, and turn the key to the project Department of Party A; The general contractor shall prepare the overall process flow construction scheme of the project from bottom to top; The subcontractor shall prepare the bottom-up flow construction scheme of the discipline according to the overall schedule of the general contractor; The general contractor shall review the construction schedule and assurance measures submitted by subcontractors, coordinate and modify the contradictions or nonconformities of each subcontract plan, and strictly supervise the implementation; The general contractor shall review the construction schedule and assurance measures submitted by subcontractors, coordinate and modify the contradictions or non-compliance of each subcontract plan with the general plan, and strictly supervise the implementation; ➤ organization principle the principle of organizing flow construction from bottom to top in the whole process: all processes organize flow construction from bottom to top, and there is only one professional construction in each flow section.

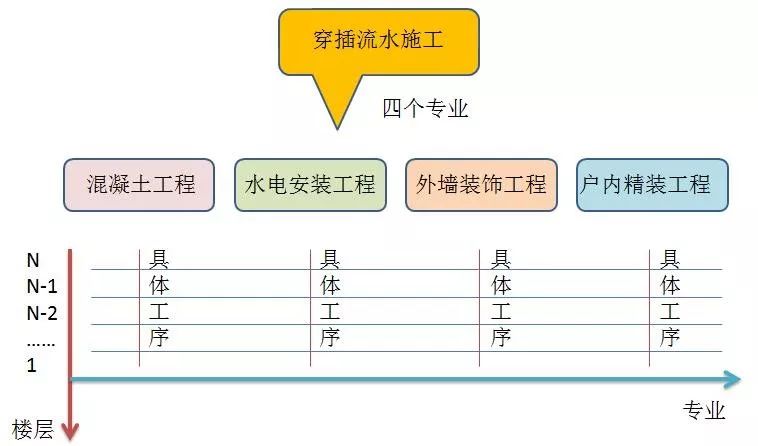

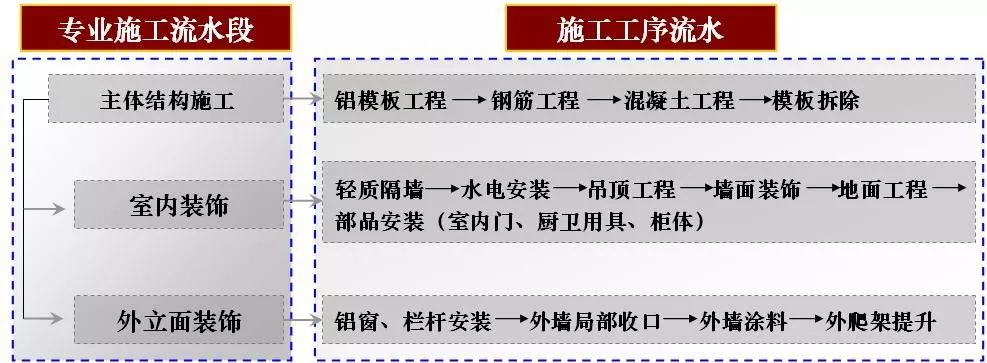

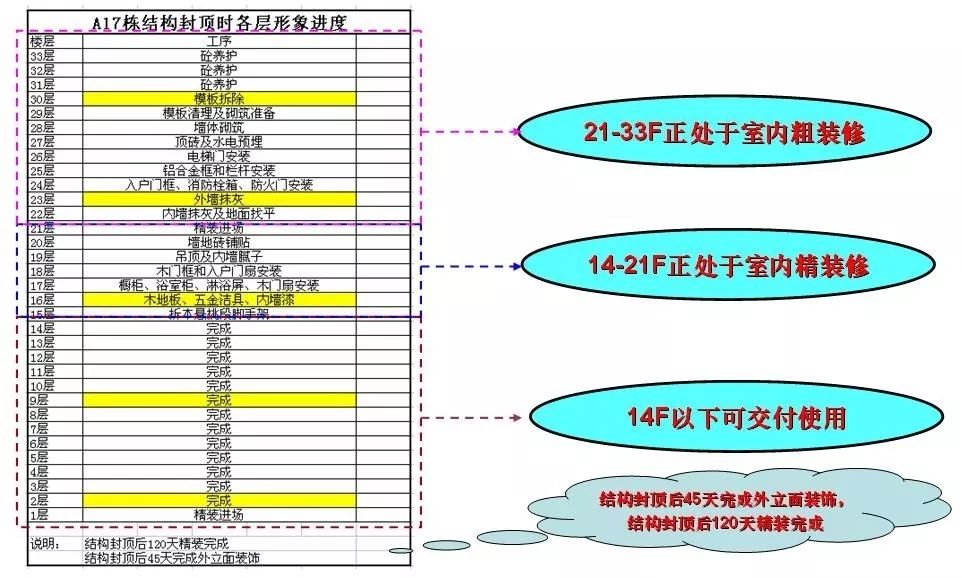

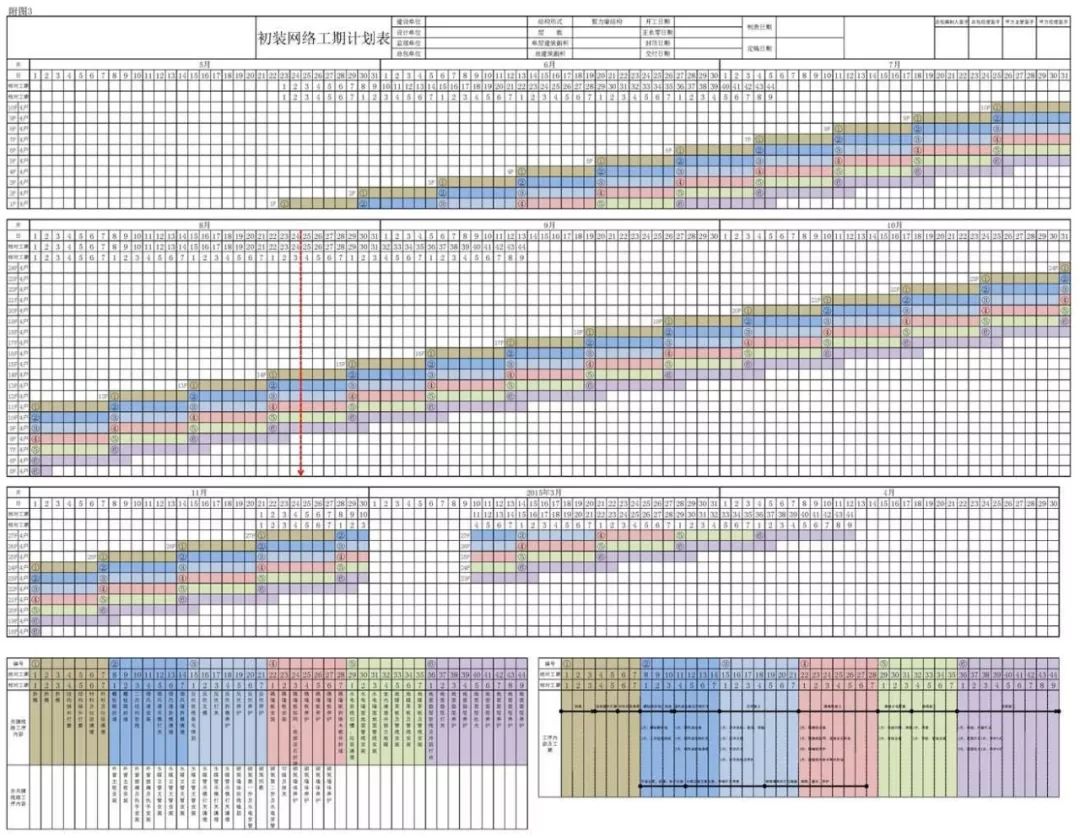

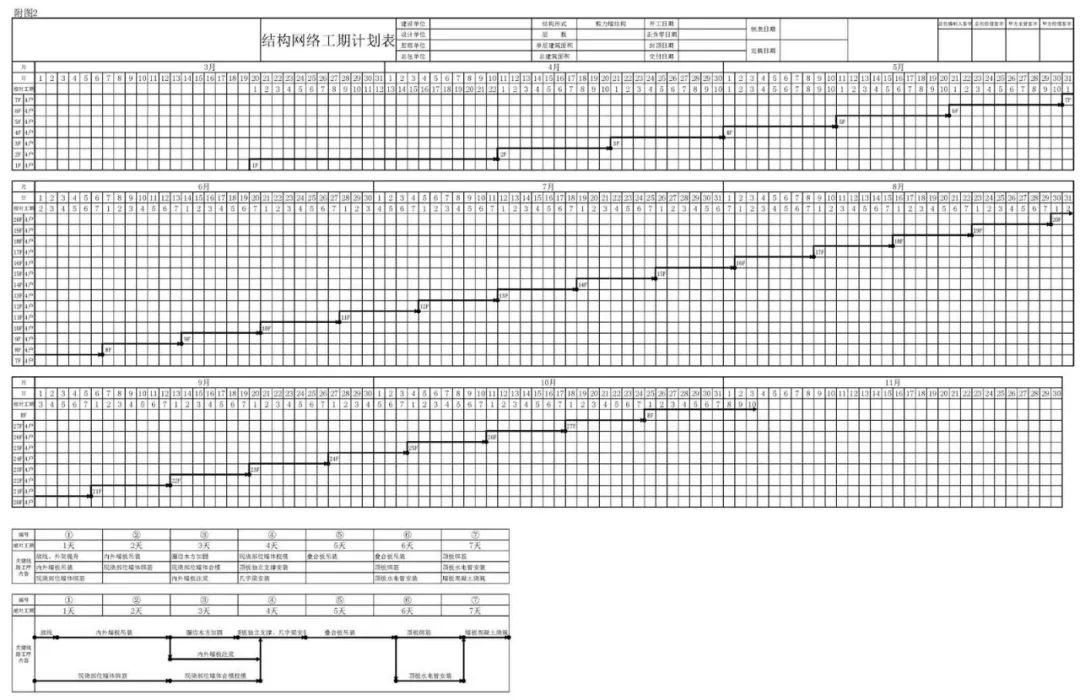

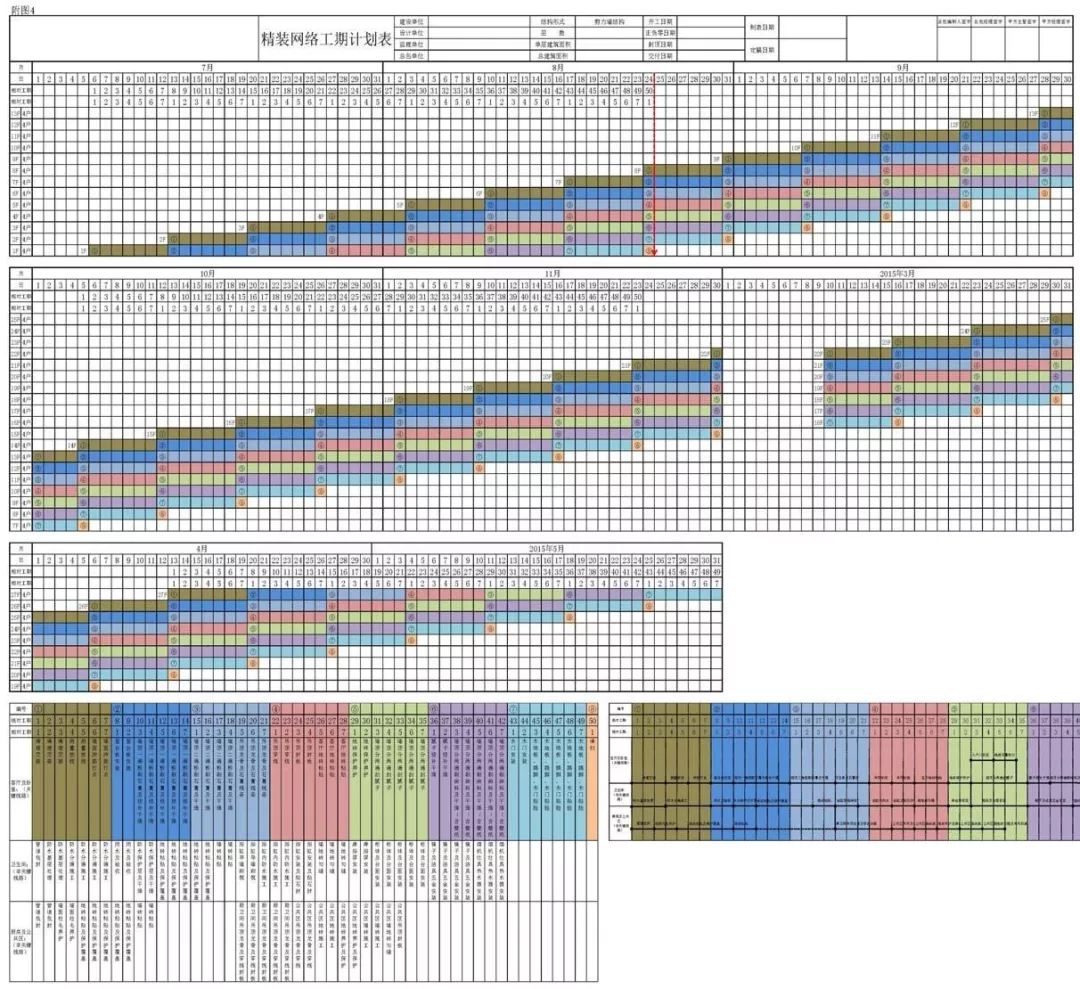

Construction process flow ➤ organization flow of interleaved flow construction management to achieve the objective of interleaved flow construction, the realization scheme of the overall objective of the project plan is broken down as follows: 1 Using network schedule management 2 Initial installation vertical interspersed to improve efficiency 3 Fine decoration vertical interleaving to improve efficiency 4 Reasonable flow operation of single process (completion of fine decoration construction of N-18 floor) 5 See the following figure for the overall network construction schedule of interior and exterior decoration synchronous construction: see the following figure for the structure network construction schedule: see the following figure for the initial installation network construction schedule: see the following figure for the hardbound network construction schedule: the single building is divided into three parallel professional construction flow sections: main structure, interior decoration and facade decoration.

Source: the flow construction management technology for Luban union construction project of construction engineering has been widely used in on-site construction in Japan, but it is rarely used in China.

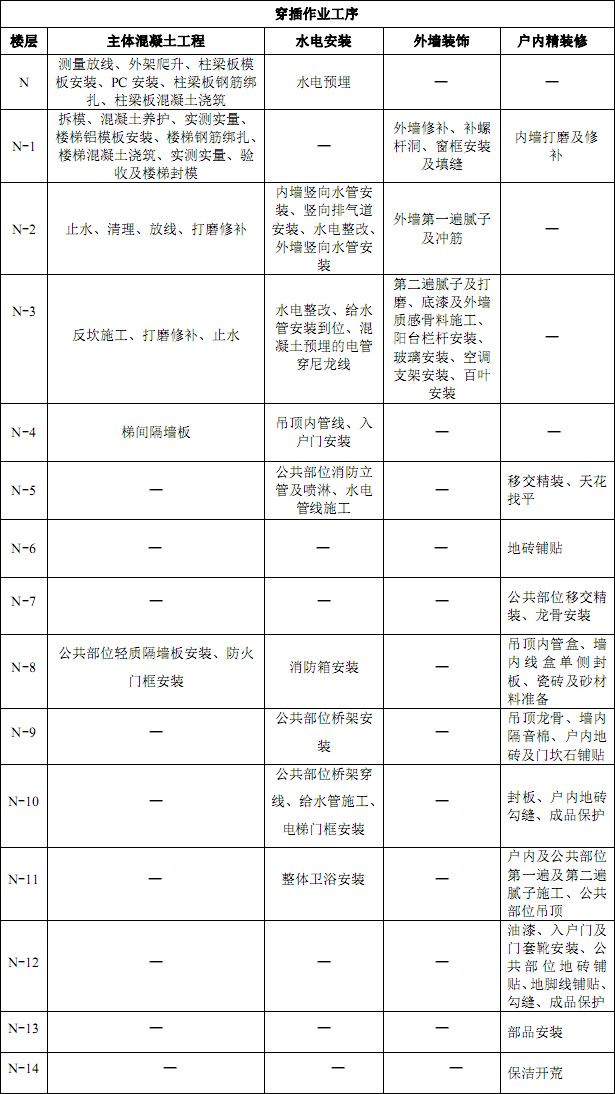

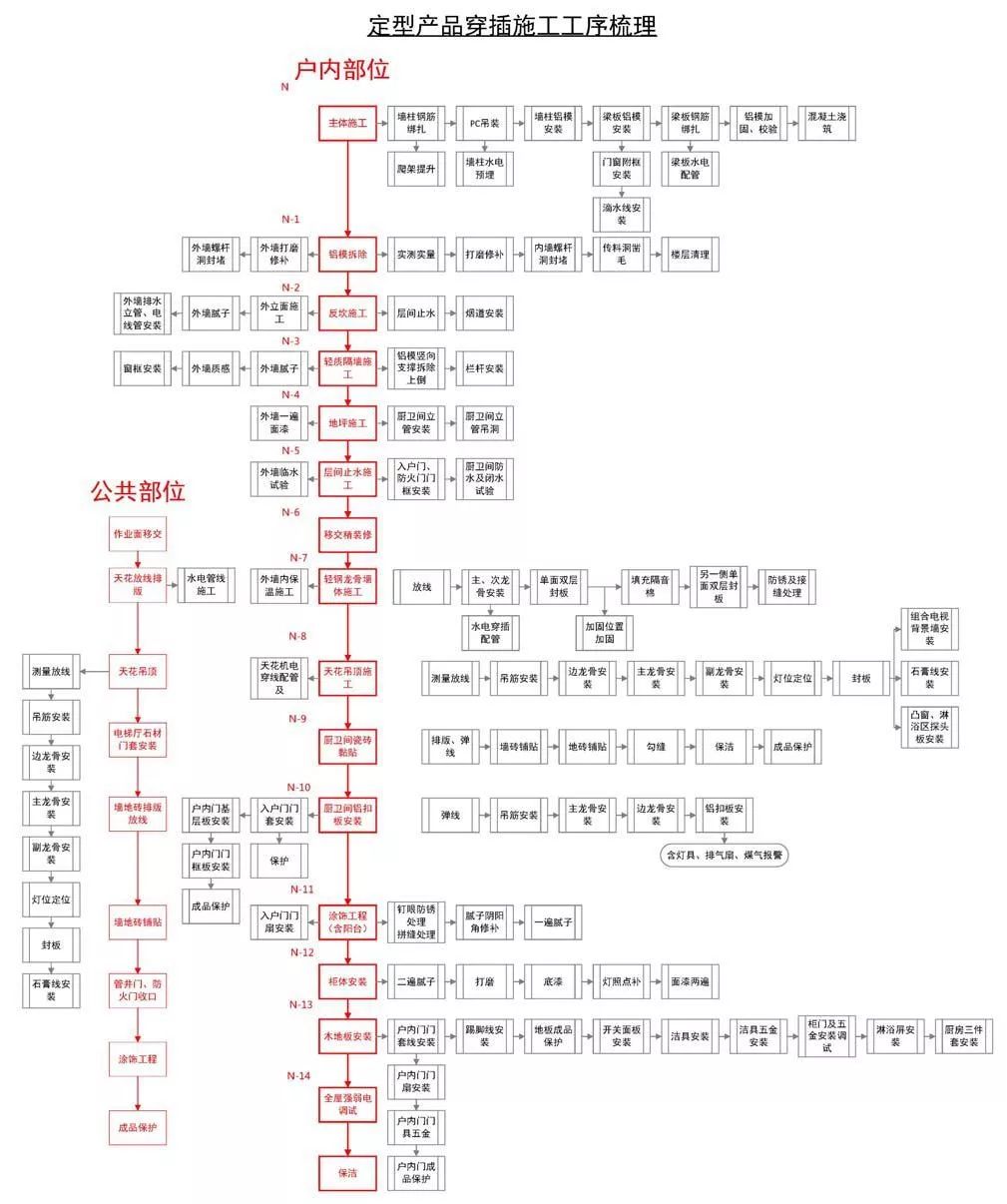

The specific construction procedures of interleaved flow construction management in the table below are the summary of the experience of multiple projects and the core implementation content of interleaved flow construction: construction procedure table of interleaved flow construction management ➤ comprehensive application of process principles, such as all concrete exterior wall, aluminum formwork, light steel keel partition wall, structural joint Many advanced technologies and management tools under existing conditions, such as high-rise construction lifting platform, light partition board and integral bathroom, form an effective interspersed operation construction management organization system, practice the “two mentions and one reduction” of Vanke Group, promote the realization of Vanke Group’s “three-year quality dream”, and provide a reference example for the company and other companies in the group.

Interleaved construction is a process organization and management technology.

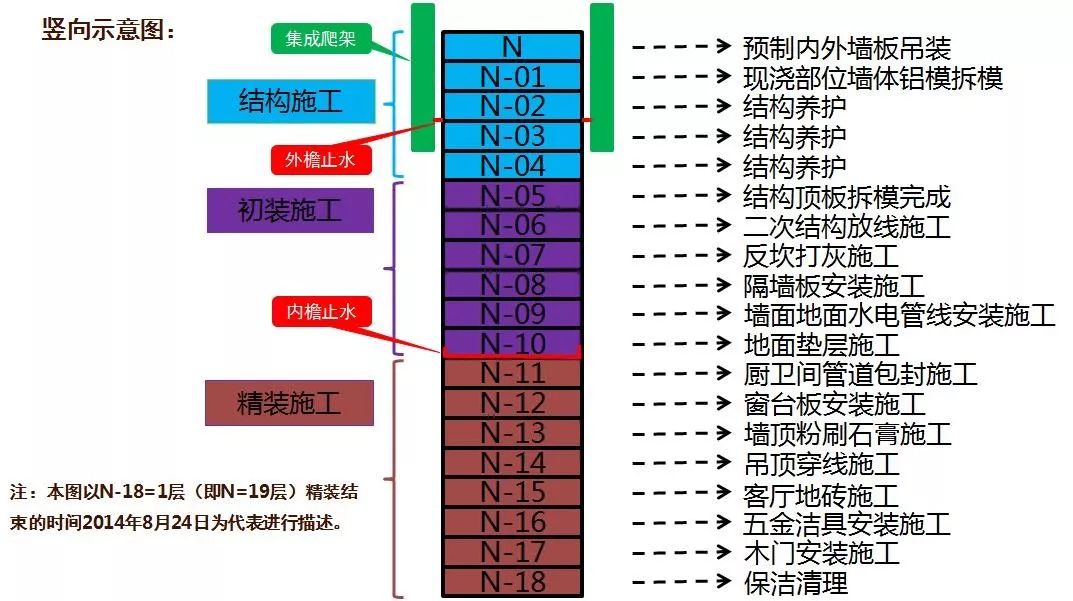

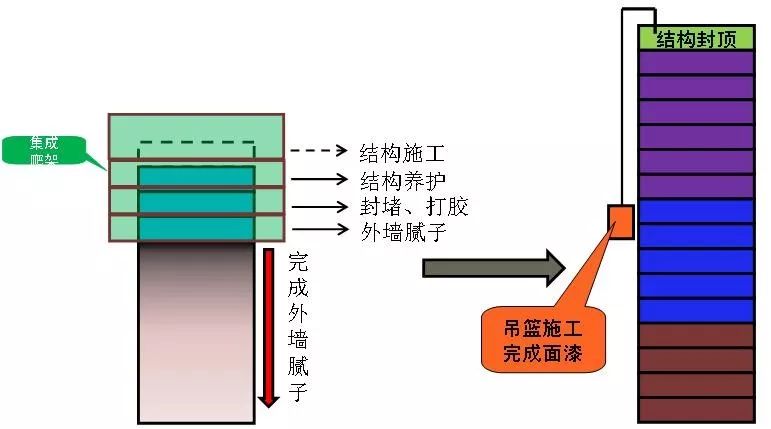

Construction method characteristics the peripheral structure of the construction project of the interleaved method adopts the shear wall structure, and comprehensively uses the new technologies such as climbing frame, aluminum alloy formwork and fabricated inner wall panel to realize the internal and external wall plastering free, reduce the external wall leakage, hollowing and cracking, and achieve the purpose of improving the quality.

Construction period diagram (3) since the construction flow rate of the standard layer of the structure is 7 days, in order to realize the reasonable flow of the initial installation and structure, the construction flow rate of the key lines of the initial installation is also determined to be 7 days.

The six processes of main structure, internal partition board, aluminum alloy door and window installation, exterior wall coating, interior wall, putty and floor tile paving adopt layer by layer flow, and other processes adopt set flow; The interior decoration, exterior decoration (including balcony and entrance garden) and public staircase (including the household where the people and goods elevator is located) do not intersect in the plane, nor do their own running water; The flow section on each floor shall be arranged in the order of exterior decoration – interior decoration – public staircase and the suite where the people and goods elevator is located.

Therefore, before inserting the initial installation, it is necessary to complete the installation of the construction outer ladder.

The basic principle of construction organization and management of interleaved flow is shown in the figure below: the basic principle diagram of interleaved flow construction management.

Its purpose is to clarify the construction process flow organization requirements of the whole construction process from bottom to top, shorten the total construction period, reduce the demand for the number of labor force, and improve the refinement level of project management.

Each construction flow section shall be constructed by a professional unit.

(4) Reassemble the small process contents of the key lines of initial installation according to 7 days to form a large process content and number it..

(2) Analyze all processes of single-layer initial installation in detail, determine the total construction period of single-layer initial installation, and determine the process contents of key lines, non key lines and their relative construction period.

In the construction of interleaving method, the plastering of internal and external walls is cancelled, the construction process is simplified, the working face of each process is made full use of, and the fine decoration unit is delivered to the site for construction in advance, so as to shorten the absolute construction period by more than 20%, so as to achieve the purpose of improving efficiency.

With the continuous development of domestic high-rise housing industrialization, the technology of interleaved flow construction management will also be widely used in China.

Taking the project as an example, it is the most reasonable time node to insert the initial installation of the first floor during the construction of the sixth floor structure.

In the initial installation construction, the key is to solve the problem of vertical transportation.

Each construction area shall organize flow construction in sequence to form three flow operation processes.

With the long construction period and high labor demand of high-rise buildings, and the increasing wages and costs of workers, it is imperative to adopt the interspersed flow construction management technology in order to improve the construction efficiency.

Construction flow chart ➤ overall construction process flow of interleaved flow 1 The overall construction process of stereotyped products is interspersed with the overall construction process of stereotyped products 2 The first step is to realize the vertical interspersed efficiency of initial installation according to the overall network construction period plan.

The general contractor shall reasonably coordinate and allocate labor force and organize the overall interspersed construction.

(1) Take the initial installation start node of the 27th floor as the key line of the whole project, and reverse the initial installation start node of the first floor.