During the closure, the support that restricts the longitudinal deformation of the beam body should be removed as far as possible to facilitate the longitudinal deformation of the beam body.

The linear deviation of the side span closure section is too large.

(2) In order to reduce the interaction between the shrinkage and creep of the concrete in the straight-line section and the cantilever section, and considering that the straight-line section should not be poured too early to avoid cracks caused by foundation subsidence, the construction time of the side span straight-line section is basically synchronized with the last beam section of the cantilever section.

(2) When closing, one end of the side span section has strong longitudinal restraint with the support, which is not relaxed in time, resulting in large secondary stress in the beam, cracking the concrete or deforming the support, affecting the alignment.

(3) In addition to checking the overall stiffness and stability of the support, measures such as preloading, setting the adjustable base of the support, reserving sufficient camber and throwing height can be taken to control the final settlement value of the construction.

The deformation of the cast-in-place section of the side span is too large.

The longitudinal and vertical deformation, overall stiffness and stability during construction should be estimated and verified item by item..

(2) The support foundation sinks too much, resulting in the deformation of the support.

(3) The support sinks, resulting in excessive deflection of the closure section, and the alignment does not meet the design requirements.

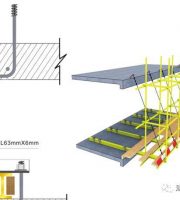

1.3 preventive measures (1) select the appropriate support form and formwork system according to the quantities of cast-in-place sections, construction equipment, foundation bearing capacity and other factors, and determine the construction method of one-time formwork erection and pouring.

(4) The support of closure section shall have large rigidity, and the throwing height value shall be reserved.

1.

A Teflon sliding plate can be set between the support and the beam to eliminate the adverse effect of longitudinal deformation on the stability of the support.

1.1 phenomenon: the support sinks during construction, causing the alignment of the cast-in-place section to be inconsistent with the design.

2.

(3) The stiffness of the support is not enough, the construction load is too large, or the elastic deformation of the support members and the inelastic deformation of the nodes are not estimated enough when designing the support.

If the construction method of one-time formwork erection pouring or segmental pouring, setting construction joints and final closure is not reasonably selected according to the quantities, foundation bearing capacity and construction capacity of the cast-in-place section.

(3) The advance direction of the pouring of the straight-line section of the side span should make the permanent support bear the force evenly, so as to avoid the possible uneven deformation caused by one-time loading.

1.2 cause analysis (1) construction methods and technical measures are not well considered.

For example, the deflection in the middle of the span is too large, and even concrete cracks appear.

Click the blue words above to pay attention to the prevention and treatment of common quality problems in the cast-in-place construction of our support.

(2) The support foundation adopts soil replacement, pile foundation and other methods to strengthen the foundation according to the bearing capacity and load of the foundation, so as to reduce the settlement of the support.

At the same time, the connection between the support beam and the pier body should be strengthened to make it bear a certain additional horizontal force.

2.3 prevention and control measures (1) longitudinal deformation will occur during the closure, pre construction stress and temperature change of the straight section of the side span.

2.2 cause analysis (1) when closing, the temperature difference is large or after applying longitudinal prestress, there will be large longitudinal deformation, and the shrinkage and creep of concrete will also increase the longitudinal deformation with the growth of age.

2.1 phenomenon: the longitudinal deformation of the side span closure is large, or secondary stress cracks occur in the beam body, and the support deformation affects the side span alignment.