(2) If the scratches in the rough grinding stage cannot be removed after the next mesh of diamond cutter head is grinded, it can be removed by changing the resin grinding disc with the same mesh.

Construction method of cement self leveling floor 10.

The softer the ground is, the more early the curing agent is and the greater the consumption is.

PS: the water grinding disc is thin, generally between 2-3mm thick.

Complete version of construction scheme for emery wear-resistant floor! 4.

(4) Joint repair: the function principle of the sealing curing agent determines that it naturally has the characteristics of repairing ground defects (except for defective products).

Cement self leveling PK epoxy self leveling, which type do you prefer? 3.

The advantages of water mill are dust-free, easy to clean, less auxiliary tools, low abrasive wood formation, and low initial investment cost.

▲ Henghe Yongsheng ▲ Tianjin Yushen building step1 determine the construction scheme before determining the construction scheme, the first thing to determine is the ground condition, including construction volume, concrete grade, flatness, aggregate properties and adverse surface factors.

How much do you know about the solidified floor? 7.

The common unfavorable factors in China include many types, such as pores, cracks, sanding, dusting, honeycomb, pitted surface, oil pollution and so on.

After 800 meshes, the normal ground has a certain gloss.

The advantages of dry grinding are dust-free, pollution-free, high grinding efficiency, better gloss, less scratches and easy to find.

The disadvantage is that the machine cost is high, and the industrial vacuum cleaner is large and inconvenient to move.

(epoxy mortar can also be used to repair) PS: rough grinding scratch problem (1) during rough grinding, the diamond particles in the abrasive are relatively large, which is prone to scratch.

In addition, the rotating speed of the grinding machine is too fast (the rotating speed of the machine should not exceed 800rpm, and the frequency should be controlled below 30 Hz), the levelness of the grinding head of the machine is poor, and the ground J is not thoroughly cleaned are all the inducing factors of scratch.

Step2 rough grinding rough grinding is aimed at the old land with poor ground conditions or the new land with poor flatness.

However, the concrete curing floor is often used for industrial floors.

(2) The technology of concrete curing floor is derived from the stone grinding and renovation technology.

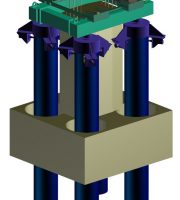

(1) The grinding machine with 12 or more grinding heads is suitable.

Therefore, many construction units have the habit of using dry grinding disc (about 15mm thick) for water grinding construction, which is a compromise method.

The smaller the mesh number, the greater the grinding force.

Estimate the rough grinding depth according to the ground flatness, select the model of rough grinding consumables and the time to add curing agent according to the ground hardness, and finally allocate machines and personnel in combination with the construction area.

Floor dry goods: I will teach you how to make floor paint on old cement floor Disclaimer: today’s terrace platform release, excerpt.

One of the construction areas is large and the site is open.

Many construction units directly use the traditional process of stone grinding, water grinding machine and water grinding sheet.

How to solve the difficulties of low temperature construction of epoxy floor? 9.

Excellent enterprise recommendation ▲ xiupo chemical ▲ July 15-17, 2022 ▲ August 13-15, 2022 ▲ October 19-21, 2022 article selection 1.

(2) The abrasive is usually 30-50 mesh diamond bit.

The greater the grinding expansion, the better the flatness.

self leveling ground leveling construction technology 2.

The following will introduce the differences between dry grinding and water grinding processes and the impact of the birth of new polishing machinery on the process.

Excellent enterprises recommend ▲ Huizhi diamond light ▲ sankeshu coating ▲ litek: 13925595097step3 fine grinding refers to the grinding of the ground after rough grinding and before polishing, that is, from 200 mesh resin sheet to 800 mesh resin, and most of the ground is sealed with curing agent at this stage.

For example, the scratches grinded by the 50 mesh diamond cutter head should be removed by using the 50 mesh resin grinding disc.

If the ground has been coated with sealing curing agent, it needs to be grinded twice more.

Dry mill or water mill? (1) In the field of traditional stone, from grinding and renovation to crystal surface crystallization, water grinding is the main method.

Construction scheme of epoxy resin self leveling floor (full version) 8.

For new ground with good flatness, first use a grinder equipped with 300-500 particle size grinding plates for fine grinding, and then apply a sealing curing agent.

Therefore, the dry grinding process equipped with large industrial vacuum cleaners is gradually widely used.

The disadvantages are low grinding efficiency, high labor intensity, easy to produce sand marks, and environmental pollution caused by sewage.

Use professional floor grinding machinery to grind the ground to a solid base, and polish the loose, delaminated, greasy dirt, and dusty land, so as to achieve the flatness required for subsequent construction.

Many old blood reconstruction projects are also required not to affect normal production.

Step4 polishing uses the grinding and polishing characteristics of high-speed polishing machine.

Choose the time to apply the curing agent according to the ground hardness.

(3) For the ground with soft ground but small grinding depth, the hardener can be applied first to increase the ground hardness before grinding.

Why are micro cement and micro cement tiles so popular? 6.

After the curing agent is fully absorbed, use 1 #, 2 # 3 # pad (800 mesh, 1500 mesh, 3000 mesh) high-speed polishing machine can polish the concrete floor with sealing curing agent without exposing the aggregate.

Construction of emery wear-resistant floor and curing agent 5.

Combined with the grinding machine, apply the sealing curing agent after rough grinding, and then sprinkle an appropriate amount of concrete ash brought out by rough grinding, and grind with a 50 mesh metal knife head, which can effectively repair cracks and small holes.

The construction requires frequent replacement of abrasives, which seriously delays the construction efficiency.