③ When the heating pipe or water supply pipe needs to pass through the inverted sill vertically, the form of reserved groove shall be adopted to avoid secondary slotting.

Forming effect of anti crack notch in thin masonry construction and pipe laying construction 7.

Shaping effect of semi-finished products of the stereotypical hoop bending machine shaping effect 5 inverted sill construction 1.

Roughening of inverted sill roughening effect of inverted sill 2.

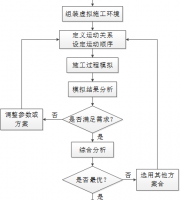

The template review project department will decompose each process of masonry, identify important control nodes, clarify the operation standards and product acceptance standards of each process, check whether the construction process is consistent with the standards, correct the deviation in time, solidify the construction standards, form the template review results, and guide the masonry construction of subsequent floors.

If it exceeds the requirements, the scraper with steel teeth can be used for local grinding.

② When the water supply pipe passes through the inverted sill transversely, the “U” type anti-seepage casing shall be used to avoid leakage passage.

Optimize the height of guide wall, adjust the height of guide wall in coordination with masonry layout, reduce the model of non-standard blocks and reduce material loss.

Anti seismic measures: anti seismic measures shall be set every 2 bricks, and reinforcement can be planted or L-shaped corner codes can be used.

The dustpan shall be set at the upper opening of the structural column of the secondary structure construction of anti-corrosion wood top plug and micro expansion concrete top plug 8; For the reinforcement of structural column formwork, it is forbidden to perforate on the masonry, and the split screw shall be set inside or at the side of the structural column.

3.

Slotting effect of bar planting slotting machine 2.

At the same time, it is required to snap the side line of door and window opening, 1m line of building, vertical axis of wall column and position line of planting reinforcement, and make marks to facilitate inspection and guidance of construction.

2.

The verticality control shall be measured at the same time of laying.

Base course roughening: for the concrete inverted sill set in the kitchen, toilet, bathroom, etc., use ink lines to pop up the boundary line of the area to be roughened.

The masonry pipe wrapping construction process is adopted to invert the traditional masonry, slotting, line pipe installation and other processes.

The wall layout is convenient for the centralized processing of special-shaped bricks and reduces the material loss.

Anti leakage U-shaped water bending pressure groove forming effect of inverted sill formwork support 6 wall masonry 1.

The secondary piping can be slotted with a special slotter, or the pipe laying process can be used in the masonry stage.

The key points of the on-site inspection process are fine setting out and precise setting out of the double-sided control line of the wall and the number of poles.

The slotting machine can adjust the distance from the edge and can process blocks of various widths such as 200mm and 100mm.

The article is transferred from actual project management.

Block with size of 600 * 185 * 240mm shall be used, and the width shall be consistent with the width of shear wall after pressure groove pressing.

The pull-out strength is more guaranteed than the traditional embedded bar method, and the forming quality is reduced, and the technical intermission after the embedded bar is reduced.

It is prohibited to set cement support and positioning bar in the inverted sill.

After the mortar joint squeezing block is in place, the mortar shall be squeezed to ensure that the mortar is uniform and the mortar joint is not more than 4mm.

The top of the brickwork shall be caulked with a gap of about 30mm, wedged with triangular anti-corrosion wood for positioning, and caulked after 14 days.

Fine setting out shall be carried out on the layout planning site.

The expansion bolt type embedded bar of PC4 prefabricated strong and weak current box of door opening wood brick adopts the expansion bolt + anchor plate welding type embedded bar.

Mortar scraping: use special tools to scrape serrated mortar on the masonry surface of the block, and then install it in place.

Prefabrication of indoor strong and weak current boxes and wood bricks at the door opening.

The slotting of this process is inside the block, with excellent surface appearance, and there is no later slotting and groove filling process, so as to reduce the risk of hollowing and cracking in the later stage.

The depth needs to remove the structural stone surface, and the vertical joint surface is the same.

The bell mouth is provided with structural column formwork and the forming effect of structural column 9.

The construction setting out of the secondary structure shall be carried out in advance.

Based on the example of high-precision masonry implemented by Zhongtian Group project, this paper comes to the site to learn the construction technology.

Fine setting out fine setting out fine setting out fine setting out fine setting out fine setting out red painting precise mark of planting reinforcement point 3 centralized processing 1.

Part of the special-shaped blocks and the blocks at the covered parts are cut in a centralized manner.

Construction of inverted sill: ① during the reinforcement of concrete inverted sill formwork, the stereotyped “U” beam clamp and presser foot formwork shall be used.

Use a hand-held (pneumatic) concrete roughening machine to gently contact the roughing head with the concrete surface and move the roughing machine to roughen.

Equipped with a shaped slotting machine, assign special personnel to make reserved slots for planting reinforcement in masonry to ensure the accuracy of planting reinforcement position.

It is required to pop up the double-sided control line of the wall to control the position of the wall and the thickness of the plastering layer.

2.

The stirrups and planting bars are processed by the shaped hoop bending machine, with accurate dimensions and correct angles.

The masonry layout shall be pasted to the corresponding positions on the site to guide the operators to correctly divide and assemble the materials and improve the construction energy efficiency.

Tomorrow will be more exciting..

About 30mm gap shall be reserved at the top of top caulking masonry, and triangular anti-corrosion wood shall be wedged, and caulking treatment shall be carried out after 14 days.

The base course shall be leveled with mortar.

If it is not flat, it can be leveled with 1:3 mortar.

Construction process 1 deepening design 1.

Before the construction of high-precision blocks, the base course floor shall be flat.

Thank you for your attention.

It shall be poured with the inverted sill at one time and vibrated and compacted.

The water and electricity are first, and the line pipe installation is arranged in advance.

After anti cracking treatment of pressure groove hanging net at the junction, the shear wall can directly enter the decoration batch or gypsum mortar thin plastering construction; The height of 2-skin block is 480mm, which meets the specification requirement that the spacing between tie bars is not more than 500mm.

Your every message and every praise are the driving force for our progress! If the article is helpful to you, please forward it to your relatives and friends! Compared with the traditional masonry construction, the high-precision masonry has many advantages, achieving the purpose of reducing cost and improving quality and efficiency: dry construction, which is convenient for the construction process; Simple construction, high perpendicularity and flatness, and free / thin plastering; The block has high strength and less shrinkage, which reduces the risk of hollowing and cracking in later plastering.