Please pay attention to the industry information | road lookout finds different civil engineering wechat カ highway outlook wechat has been revised again 叒 many new friends say that they can’t find the road

.

Click “road lookout” on the top of the king point → click “…” on the top right corner → click “set as star” カ to add a star to “road lookout”, so they won’t pass by! 1、 The basic knowledge of pile foundation 1

.

Pile foundation pile foundation is one of the most widely used foundation forms in deep foundation, which is composed of several piles sunk into the soil and the pile cap or bearing beam connecting the pile top

.

2

.

The role of pile is to transfer the load of the upper building to the deep soil layer with strong bearing capacity, or to compact the soft soil layer to improve the bearing capacity and compactness of the foundation soil

.

3

.

Pile classification (1) according to the stress situation, end bearing pile: it is the pile that passes through the soft soil layer to reach the hard soil layer or rock layer, the load of the upper structure is mainly borne by the resistance of the rock layer; during the construction, it is mainly to control the penetration, and the depth of the pile tip into the bearing layer or the elevation of the pile tip can be used as a reference

.

Friction pile: it is completely set in the soft soil layer, and the soft soil layer is compacted to improve the compactness of the soil The load of the upper structure is borne by the resistance of the pile tip and the friction resistance between the side of the pile and the foundation soil

.

During the construction, the design elevation of the pile tip is mainly controlled, and the penetration can be used as a reference

.

(2) according to the construction method, the precast piles can be classified: according to the method of sinking into the soil, they can be divided into driven pile, water flushing pile, vibration pile and static pile

.

Cast in place pile: it is a pile formed by forming a hole at the pile position, then placing the reinforcement framework and pouring concrete

.

According to different hole forming methods, cast-in-place piles include bored cast-in-place pile, dug cast-in-place pile, punched cast-in-place pile and immersed cast-in-place pile

.

2、 Production process of prestressed pipe pile prestressed concrete pipe pile rolling pipe pile driver guide rod pile driver walking pile driver three-point support crawler pile driver diesel hammer hydraulic hammer extra large hydraulic hammer (with muffler cover) 1

.

Application scope of pipe pile (1) prestressed high strength concrete pipe pile (code PHC) and prestressed concrete pipe pile (Code PC) are applicable to the foundation of industrial and civil buildings Foundation

.

The basic design of railway, highway and bridge, port, water conservancy, municipal engineering and structure engineering can also be used

.

(2) Prestressed concrete thin-walled pipe pile (code PTC) is suitable for the foundation of industrial and civil buildings

.

(3) PHC pile and PC pile are suitable for the area with seismic fortification intensity less than 7 degree; if they are used in the area with higher seismic fortification intensity, they need to be checked separately

.

(4) PTC pile is suitable for the area with seismic fortification intensity less than 7 degree, and the area with seismic fortification intensity of 7 degree shall be checked separately; PTC pile shall not be used for the area with seismic fortification intensity greater than 7 degree

.

(5) When the environmental and geological conditions of foundation engineering are corrosive to the pipe pile, effective technical measures should be taken

.

(6) The pipe pile is mainly considered to bear vertical load

.

2

.

The main construction methods of pipe pile foundation are as follows: (1) hammering method: diesel hammer and hydraulic hammer; (2) static pressure method: hold pressure hydraulic pile driver; top pressure hydraulic pile driver; hold pressure and top pressure combined hydraulic pile driver; hold pressure vibration hydraulic pile driver; (3) drilling (pressing); (4) drilling pile planting method; (5) medium excavation method (diameter ≥ 600)

.

3

.

This paper mainly introduces the working principle of diesel pile driver, which is composed of diesel pile hammer and pile frame

.

There are special pile frames, and they are also refitted by adding gantry frame to the long boom boom of excavator or crane

.

According to its action characteristics, diesel pile hammer can be divided into two types: guide rod type and cylinder type

.

The impact body of the guide rod pile hammer is a cylinder, which has simple structure but low driving energy; the impact body of the cylinder pile hammer is a piston, which has large striking energy and high construction efficiency, so it is a widely used driving equipment at present

.

(1) When diesel and compressed air are injected, the upper piston falls down and impacts the fuel rod, which makes the fuel pump inject a certain amount of diesel hammer to the impact surface of the lower piston through the fuel injection nozzle

.

When the upper piston continues to fall through the suction and exhaust port, it begins to compress the air in the cylinder, and the gradually increasing air pressure will press the lower piston and pile cap tightly on the pile head

.

(2) The series of diesel pile hammers use the impact energy of the free fall of the impact part and the energy of diesel combustion and explosion to make the pile sink

.

It is essentially a single stroke diesel engine with a horizontal bar

.

When the piston goes down and touches the pressure block of the oil pump, it begins to inject oil into the central ball groove of the hammer seat; when the piston goes down to close the suction and exhaust, the air is compressed, which is the process of injection and compression

.

After that, the piston goes down until it impacts the hammer seat, which produces strong impact force and makes the pile sink

.

At the same time, the diesel fuel injected into the ball groove is atomized under the action of high temperature and high pressure air and ignites

.

While the combustion and explosion force pushes the piston upward, it produces pressure on the hammer seat

.

(3) When the piston goes up over the suction and exhaust port, the exhaust gas is discharged out of the cylinder

.

The exhaust gas in the cylinder is discharged, but the piston still needs inertia upward, so fresh air is sucked in again

.

When the piston goes down again, part of the fresh air in the free cylinder is swept out of the cylinder

.

Until the piston goes down as shown in the figure

.

At this point, a working cycle (4) is completed, and the upper piston continues to rise up to generate negative pressure in the cylinder

.

Fresh air is sucked in through the suction and exhaust port, and the exhaust gas is completely swept out

.

The pressure lever of the fuel pump is released to return to its original position, and the fuel pump re inhales diesel

.

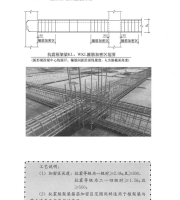

3、 The setting of piling machine, pile cap and cushion shall meet the following requirements: (1) pile cap shall have sufficient strength, rigidity and driving resistance

.

(2) The pile cap should be made into a cylinder, the depth of the cylinder for the pile head should be 350-400mm, and the inner diameter should be 20-30mm larger than the outer diameter of the pipe pile

.

(3) During pile driving, elastic cushion shall be set between pile cap and pile head

.

The liner can be made of gunny bag, cardboard, cement paper bag, plywood and other materials

.

The liner thickness should be uniform, and the thickness after hammering compaction should not be less than 120mm

.

During piling, it should be checked frequently and replaced or supplemented in time

.

(4) Between the pile cap and the pile hammer, the “hammer pad” shall be made of hard wood or coiled steel wire rope with a thickness of 150 to 200 mm

.

2

.

The setting of pile feeder and liner should meet the following requirements: (1) the pile feeder should be made into a cylinder with sufficient strength, rigidity and driving resistance

.

The length of the pile feeder should meet the requirements of the pile density

.

(2) The upper and lower ends of the pile feeder shall be flat and perpendicular to the central axis of the pile feeder

.

(3) The lower end face of the pile feeder should be perforated to connect the inner cavity of the pile with the outside world

.

(4) The pile feeder shall match the pipe pile

.

The depth of the sleeve at the lower end of the sleeve type pile feeder should be 250 to 350 mm, and the inner diameter should be 20 to 30 mm larger than the outer diameter of the pipe pile; the length of the pin at the lower end of the plug type pile feeder should be 200 to 300 mm, and the outer diameter should be 20 to 30 mm smaller than the inner diameter of the pipe pile

.

For the pipe pile with excess slurry in the inner hole, it is not suitable to use the plug pile feeder

.

(5) During pile driving operation, 1 to 2 layers of sack or cardboard should be set between pile driver and pile head

.

4、 Pile driving construction code: 1

.

It is absolutely not allowed to start the pile hammer before the pile hammer is placed on the pile head reliably and the preparation and inspection of various regulations are not completed

.

When the lower piston extends downward, it is not allowed to start the pile hammer to prevent damage to the half ring, the connecting flange or the lower cylinder

.

2

.

It is not allowed to start the pile hammer when it is separated from the guide rail of the pile frame or parked on the skid to prevent accidents

.

To prevent eccentric driving, the axial line of the pile and the center line of the pile should be overlapped as far as possible, so as to ensure that the force on the pile head is uniform and avoid accidents

.

If the pile is driven eccentrically, the hammer will swing under the action of eccentric impact, and the lower cylinder will break or deform

.

In addition, if the concrete pile may break, to prevent this phenomenon, the pile cap with guide can be used.

.