Want to do waterproof, waterproof common sense how can not know? 01 classification of waterproof Engineering (1) according to the fortification parts, 1

.

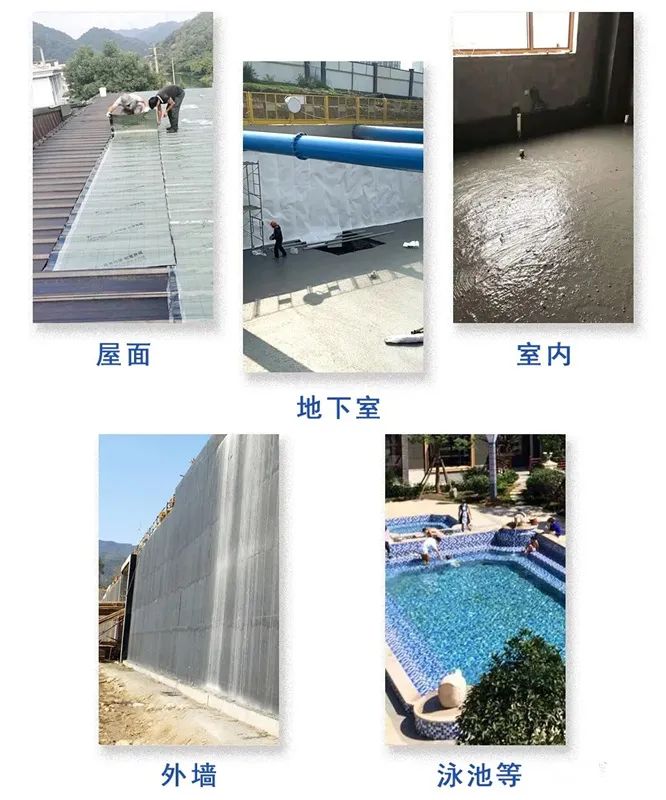

Roof waterproof; 2

.

Underground waterproof; 3

.

Indoor and toilet waterproof; 4

.

External wall waterproof; external wall facade, slope, windowsill, column edge, etc

.

5

.

Special building (structure) waterproof; such as: water tower, swimming pool

.

(2) According to the method of fortification, 1

.

Composite waterproofing

.

Rigid and flexible combination, multi-channel waterproof, comprehensive treatment

.

2

.

The construction is self waterproof

.

(3) According to the performance classification of fortification materials 1

.

Rigid waterproof

.

The waterproof layer is composed of mortar, cement slurry and waterproof mortar

.

2

.

Flexible waterproofing (1) membrane waterproofing: several layers of membrane are glued on the structural layer with cementing material to form a waterproof layer

.

It is often used in roof and underground waterproof engineering

.

It can be divided into three categories: modified asphalt membrane, self-adhesive waterproof membrane and non asphalt waterproof membrane

.

(2) Film waterproof; waterproof coating mainly includes polyurethane, polymer cement (JS), cement-based permeable crystal and other waterproof materials

.

The construction is simple and widely used

.

(4) According to the types of fortification materials, membrane waterproof, sealing material waterproof, concrete waterproof, powder hydrophobic material, penetrant waterproof

.

02 waterproofing membrane knowledge what is asphalt waterproofing membrane? The paper, fiber fabric, fiber felt and other matrix materials are dipped with asphalt, and powdery, granular or flake materials are spread on the surface to make curly flake waterproof materials

.

What is polymer modified asphalt waterproofing membrane? Using synthetic high molecular polymer modified asphalt as coating cover, fiber fabric or fiber felt as matrix, powder, granular, flake or film material as covering material, the curlable flake waterproof material is made

.

What is synthetic polymer waterproofing membrane? Using synthetic rubber, synthetic resin or their blends as the base material, adding appropriate amount of chemical additives and fillers, the sheet waterproof material can be curled through different processes, or the above materials and synthetic fibers can be compounded to form two or more layers of sheet waterproof material

.

What is reactive viscosity? Under the construction technology of wet paving method, it refers to that in the curing process of waterproof coiled material and polymer cement slurry or cast-in-place concrete, the coiled material binder forms an “interpenetrating network” interface structure between coiled material and concrete through the synergistic effect of chemical crosslinking and physical mortise and tenon, so as to achieve tight, firm and irreversible bonding effect

.

03 basic content of waterproof Engineering 1

.

Building (1) roof engineering: waterproof concrete self waterproof structure, leveling layer waterproof, coiled material waterproof, film waterproof, rigid waterproof, joint sealing waterproof, tile waterproof, gutter waterproof, pipe waterproof, drainage outlet waterproof, partition joint waterproof, overall roof waterproof

.

(2) Wall waterproof: external wall overall waterproof, parapet wall waterproof, toilet wall, deformation joint, large plate, light plate and hanging plate, vertical joint waterproof, parapet wall waterproof

.

(3) Floor waterproof: floor waterproof, floor moisture-proof, toilet floor, skirting line waterproof, balcony floor waterproof, floor through pipeline

.

(4) Waterproof of doors, windows and glass curtain wall: Waterproof of frame seam, frame leaf seam, windowsill and glass inlay

.

(5) The basement, water pump room, swimming pool, elevator pit, etc

.

are waterproof

.

2

.

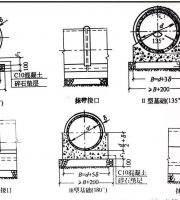

Structure (1) water tower, water tank, pool, aqueduct, gate, drainage pipe waterproof

.

(2) Subway waterproof; (3) tunnel and tunnel waterproof and drainage; (4) structural waterproof grade of special construction method

.

The waterproof grade mentioned here is mainly determined according to the nature, importance, functional requirements, structural characteristics and durability of waterproof layer of buildings

.

With the implementation of the new edition of technical code for waterproofing of Underground Engineering (GB 50108-2008) in 2008 and the new edition of technical code for Roofing Engineering (GB 50345-2012) in 2012, the waterproofing grade of building engineering can be divided into two categories: the waterproofing grade of underground engineering and the waterproofing grade of roofing engineering

.

The waterproof grade of underground engineering is divided into four grades: Grade 1, no water seepage, grade 2 and no water leakage on the structural surface

.

There may be a small amount of wet stains on the structural surface

.

For industrial and civil buildings, the total area of wet stains is not more than 0.1% of the total waterproof area, the area of single wet stain is not more than 0.1 m2, the area of any 100 m2 is not more than 2 wet stains

.

For other underground engineering, the total area of wet stains is not more than the total waterproof surface 2% of the total area, the single wet spot area is not more than 0.2 m2, and the wet spots on any 100 m2 waterproof area are not more than 3; the average water leakage of tunnel engineering is not more than 0.05l / (M2 · d), and the water leakage on any 100 m2 waterproof area is not more than 0.15L / (M2 · d)

.

There are three levels, a small amount of water leakage points, and no wire flow and sand leakage

.

The single wet spot area is not more than 0.3 m2, and a single water leakage point The water leakage is not more than 2.5l/d, the wet stains on any 100 m2 waterproof area are not more than 7 grade IV, there are water leakage points, and there is no line flow and mud and sand leakage

.

The average water leakage of the whole project is not more than 2L / (M2 · d), and the average water leakage of any 100 m2 waterproof area is not more than 4L / (M2 · d)

.

For buildings whose roof waterproof grade 1 and grade I are particularly important or have special requirements for waterproof, the reasonable service life of waterproof layer is 25 years, and the waterproof layer should be made of synthetic polymer waterproof membrane, high polymer modified asphalt waterproof membrane and metal plate 2

.

For class II important buildings and high-rise buildings, the reasonable service life of waterproof is 15 years, and the materials for waterproof layer should be polymer modified asphalt waterproof membrane, synthetic polymer waterproof membrane, metal plate, synthetic polymer waterproof coating and polymer modified asphalt waterproof membrane Water coating, fine aggregate concrete, flat tile, linoleum tile and other materials are required to have two layers of waterproof fortification; 3

.

For grade III general buildings, the reasonable service life of waterproof layer is 10 years, and the materials for waterproof layer should be three felt four asphalt waterproof membrane, high polymer modified asphalt waterproof membrane, synthetic polymer waterproof membrane, metal plate, high polymer modified asphalt waterproof coating and synthetic high polymer waterproof membrane Molecular waterproof coating, fine aggregate concrete, flat tile, linoleum tile and other materials; grade 4 and IV non permanent buildings, the reasonable service life of waterproof layer is 5 years, the waterproof layer can be made of two felt three asphalt waterproof membrane, high polymer modified asphalt waterproof coating and other materials, and the fortification requires one waterproof fortification..

.