Please click the standard atlas above to subscribe for free! 1、 Before the reinforcement installation and construction preparation site starts to bind the reinforcement, the garbage on the cushion and in the formwork shall be cleaned up

.

When binding, the reinforcement position line shall be drawn on the formwork first: the bottom reinforcement shall be marked on the cushion; the wall reinforcement shall be marked on the formwork; the column stirrup shall be marked on two diagonal lines, and the beam stirrup shall be marked on the erection reinforcement

.

After the formwork working face is cleaned up, it shall be delivered to the reinforcement team as a whole

.

2

.

The minimum anchorage length La and anti-seismic anchorage length Lae of the tensile reinforcement shall meet the requirements of 16g101-1 specification

.

3

.

Column reinforcement installation (1) column reinforcement binding

.

1

.

Pop up the column positioning control line on the floor concrete to check the position of the column

.

If the deviation of the main reinforcement exceeds the specification, it shall be timely checked After the report is submitted and the treatment plan is made by the technical director, the construction shall be carried out according to the treatment plan, and the site shall not handle it by itself

.

2

.

Stirrups for column: according to the spacing required in the drawing, the number of stirrups for each column shall be calculated

.

Firstly, the stirrups shall be set on the lap bars protruding from the lower layer, and then the column reinforcement shall be welded

.

The joints of stirrups (the joint of hooks) shall be staggered on the four corner longitudinal reinforcement

.

3

.

Draw stirrup spacing points: draw stirrup spacing points with chalk on the vertical reinforcement of welded column according to the drawing requirements

.

4

.

Column stirrup binding: according to the marked stirrup position line, move the sheathed stirrup upward and bind it from top to bottom

.

It is better to bind it with wrapping buckle

.

The stirrup and the main reinforcement should be vertical, the intersection of the stirrup corner and the main reinforcement should be bound, and the intersection of the main reinforcement and the non corner part of the stirrup should be bound in plum blossom staggered

.

The overlapping place of stirrup hook shall be staggered along the vertical reinforcement of column and bound firmly

.

The stirrups at the upper and lower ends of the column shall be densified, and the length of the densified area and the stirrup spacing in the densified area shall meet the requirements of the design drawings

.

When the stirrup is required to be provided with tie bars in the design, the tie bars shall hook the stirrup

.

5

.

Installation of column cushion block: the column adopts plastic cushion block, and the vertical and horizontal spacing shall not exceed 800mm, and the horizontal spacing shall not be less than 2

.

(2) correct method of longitudinal reinforcement lengthening (3) column reinforcement deviation treatment node ﹣ structural column reinforcement internal deviation treatment node ﹣ structural column reinforcement external deviation treatment node note: if the basement column reinforcement is out of column deviation, the column size can be appropriately enlarged without bending the column reinforcement, and the column reinforcement can be wrapped in the concrete

.

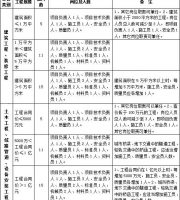

(4) Variable section column structure requirements (5) column stirrup densification structure requirements (6) column stirrup densification area scope (7) core stirrup requirements method (8) reinforcement protection layer cushion block setting requires symmetrical setting around the column (9) column longitudinal reinforcement welding connection requirements (10) positioning hoop setting requires that the initial stirrup is about 50 mm above the ground, and the column longitudinal reinforcement and beam reinforcement are firmly bound (11) column Initial stirrup 4

.

Installation of wall reinforcement 1

.

Pop up the position line of wall body and door and window openings on the floor concrete, correct the embedded joint reinforcement again, and deal with the main reinforcement of the same column in case of displacement

.

2

.

The placing order of the wall distribution bars: the vertical bars should be tied to the distance clip first, and the vertical distribution bars needed by the wall should be placed at the wall column edge and fixed slightly with the wall column

.

Then tie the transverse bar to the distance clip, and then fix the transverse bar on the wall from top to bottom

.

Finally, the longitudinal distribution bars are fixed

.

3

.

The wall reinforcement is two-way stressed reinforcement, and all crossing points of reinforcement shall be bound point by point, and the overlapping degree and position shall meet the requirements of design drawings and construction specifications

.

In order to ensure that the wall reinforcement will not shift during concrete pouring, a wall reinforcement positioning frame welded with A8 reinforcement is planned to be set on the top of each floor for positioning the relative position between two layers of reinforcement and single reinforcement

.

4

.

In order to ensure the correct elevation position of the door and window openings, the elevation lines are drawn on the vertical bars of the openings

.

The door and window openings shall be bound with coupling beam reinforcement according to the design requirements, and the length anchored into the wall shall meet the design requirements

.

In addition, the position and elevation of embedded pipe fittings and reserved holes shall meet the design requirements in cooperation with other types of work

.

5

.

The wall reinforcement cushion block adopts plastic cushion block, which is arranged in quincunx shape, and the vertical and horizontal spacing does not exceed 800 * 800mm

.

(1) Construction method of shear wall (2) anchorage structure of plate at the end of wall and column (3) standard practice of shear wall (4) reinforcement structure of reserved hole in wall and plate (5) installation of beam reinforcement 1

.

Binding of beam reinforcement should follow the principle of first frame beam, then non frame beam, first main beam, then secondary beam, first binding low span beam, and then binding high span beam

.

2

.

Firstly, the beam reinforcement should be penetrated from bottom to top, and the stirrup spacing should be drawn on the beam main reinforcement, then the stirrups should be separated one by one according to the drawn spacing

.

3

.

The stirrups for binding the upper longitudinal reinforcement of the beam shall be bound by the buckle method

.

The hook of stirrup at the overlap shall be staggered bound in the beam

.

The first stirrup at the beam end shall be set at a distance of 50 mm from the edge of the column joint

.

The stirrups at the joint of beam end and column shall be densified, and the spacing and length of densified area shall meet the design requirements

.

4

.

When the reinforcement at the joint is very dense, special attention should be paid to the clear distance between the main reinforcement at the top of the beam, which should be 30mm

.

5

.

When the main reinforcement is double-layer, the cement precast strip can be used to pad between the two layers of reinforcement, and the row spacing of cement precast strip shall be no less than 1.5m and no less than 2

.

6

.

Installation of cushion block: Marble cushion block shall be placed at the intersection of stirrup and main reinforcement of main beam and secondary beam, the spacing of cushion block shall not exceed 800mm, plastic cushion block shall be used at the side of beam, and the vertical and horizontal spacing shall not exceed 1000mm

.

7

.

When binding the beam reinforcement, the reinforcement shall be prevented from being lifted or pressed down by the water and electricity pipeline, and the lightning protection grounding shall be prevented before the acceptance of the beam reinforcement, and the end or the intersection of the main beam and the secondary beam shall be welded firmly

.

(1) Marking and positioning before beam stirrup installation (2) standard installation of beam reinforcement (3) setting of core stirrup at the junction of primary and secondary beams (4) structural requirements of beam longitudinal reinforcement lengthening position: the longitudinal reinforcement lengthening at the upper part of beam shall be within the range of LN / 3 at the middle of span, and the longitudinal reinforcement lengthening at the lower part of beam shall be within the range of LN / 3 at the support of wall and column

.

(5) Structural requirements of beam longitudinal reinforcement (6) standard practice of roof beam joint (7) standard installation of beam reinforcement (8) wrong practice of beam longitudinal reinforcement lengthening, the lengthening area at the same section is more than 50% (9) beam reinforcement binding (unqualified) (10) beam bottom reinforcement standard binding (qualified) beam bottom plate corner reinforcement full binding, middle longitudinal reinforcement jumping binding, draw hook setting in place (11) beam reinforcement spacing It is required that the clear distance between the upper longitudinal reinforcement of the beam: ≥ 30mm and ≥ 1.5D; the clear distance between the lower longitudinal reinforcement of the beam: ≥ 25mm and ≥ 1.0d

.

6、 Plate reinforcement installation 1

.

Clean up the sundries on the formwork, mark the main reinforcement on the formwork with chalk, and distribute the reinforcement spacing

.

According to the delimited spacing, the main load-bearing reinforcement and the distribution reinforcement shall be placed

.

The embedded parts, wire pipes and reserved holes shall be installed in time

.

When there is a slab with beam in the cast-in-place slab, the slab with beam reinforcement should be bound first, and then the slab reinforcement should be placed

.

When binding the bottom reinforcement of the slab, check whether both ends extend into the beam

.

When binding the slab reinforcement, generally use straight buckle or eight shaped buckle

.

Except that the intersection points of the two peripheral reinforcement should be all bound, the other points can be staggered bound

.

Each intersection point of negative moment reinforcement shall be bound

.

2

.

The distance between the finished horse stools shall not be more than 1000mm * 1000mm

.

Only then can the acceptance of concealed reinforcement be organized

.

3

.

The vertical and horizontal spacing of the lower layer of the slab shall be no more than 800mm * 800mm, arranged in quincunx shape

.

4

.

When binding the slab reinforcement, the reinforcement shall be prevented from being lifted or pressed down by the water and electricity pipeline

.

5

.

After the steel mesh of the slab is bound, the negative reinforcement on the upper part of the slab shall be paid attention to to to prevent it from being stepped down; especially for the cantilever slab such as awning, overhanging eaves and balcony, the position of the negative reinforcement shall be strictly controlled to avoid fracture after formwork removal.

.