Starting from March 15th, Foshan will carry out a special rectification of scaffolding engineering.

Cuplock Scaffolding Manufacturers

In order to conscientiously implement the requirements of the National, Provincial, and Municipal Three Year Action Plan for Safety Production (2024-2026), further strengthen the supervision of safety production in housing construction, and effectively solve the problems of substandard materials, non-standard installation, and prominent safety hazards in construction scaffolding, our bureau has decided to extend the period from March 15, 2024 to September 30, 2024, Carry out special rectification of construction scaffolding for housing construction projects throughout the city (hereinafter referred to as special rectification)..

(1) Overall requirements. Effectively implement all responsibilities, implement regulations, systems, and standards, enhance the ability to ensure construction safety production, and ensure the continuous and stable improvement of the construction safety production situation in the city..

(2) Rectification objectives. Through special rectification, we will strengthen the organization and management of construction sites, promote the implementation of the main responsibilities of all parties involved in engineering construction, further standardize the use of construction scaffolding, continuously improve relevant regulatory systems, improve the safety production status of construction sites, and make every effort to prevent collapse accidents of construction scaffolding..

(1) Rectification time. March 15th to September 30th..

1. Enterprise security management situation. The responsible parties involved in the construction project have implemented the “Regulations on Safety Management of Sub projects with High Risk” (Order No. 37 of the Ministry of Housing and Urban Rural Development), the “Notice of the General Office of the Ministry of Housing and Urban Rural Development on Relevant Issues Concerning the Implementation of the Regulations on Safety Management of Sub projects with High Risk” (Jianbanzhi [2018] No. 31), and the “Construction Safety Inspection Standards” (JGJ59-2011); The establishment of a quality and safety assurance system on the construction site, the performance of management personnel such as project leaders of the construction unit, project managers and technical leaders of the construction unit, and project directors of the supervision unit on duty, as well as the allocation and performance of full-time safety management personnel on the construction site..

2. Plan preparation and approval status. Whether the content of the special construction plan for scaffolding is comprehensive, whether it follows the approval process of construction and supervision unit review in accordance with the Safety Management Regulations for Sub projects with High Risk, and whether the special construction plan for scaffolding and formwork support projects in hazardous projects exceeding a certain scale is subject to expert argumentation in accordance with the prescribed requirements..

3. Enterprise qualifications and personnel management situation. Whether the engineering project has subcontracted professional engineering to qualified contracting enterprises (template scaffold professional contracting qualifications) in accordance with regulations, and whether on-site scaffold operators have obtained special operation qualification certificates for construction scaffolding..

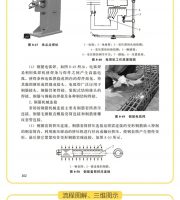

4. Material entry inspection and acceptance status. When materials such as steel pipes, fasteners, adjustable brackets, and dense mesh are used in the construction of the frame, are witness sampling conducted according to batches and sent to those with corresponding testing qualifications.